Umatshini wokushicilela weglasi yeglasi yeglasi

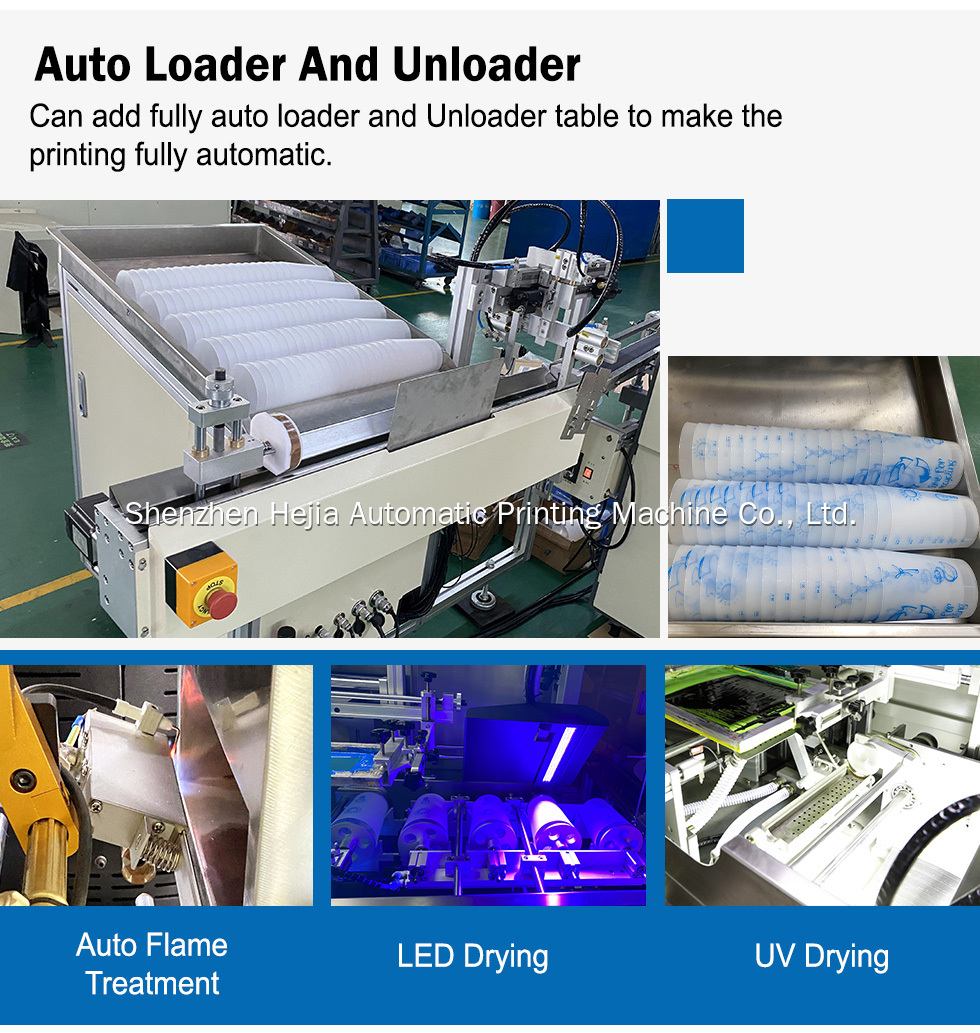

Intshayelelo Umatshini wokuprinta weglasi wePlasitiki weS102C sisixhobo sokushicilela esenzelwe izinto ezingqukuva okanye ezigobileyo ezifana neekomityi zeplastiki. Inkqubo yayo yokusebenza kukulayisha ngokuzenzekelayo kunye nokukhulula, kulandelwa unyango lwedangatye, ukuprinta, ukomiswa kwe-UV ye-LED okanye ukomiswa kombane kwe-UV, kwaye ekugqibeleni ngokuzenzekelayo...

S102C Plastic ikomityi yoshicilelo screen umatshini wokushicilela sisixhobo yoshicilelo eyenzelwe izinto ezingqukuva okanye egobileyo ezifana iikomityi zeplastiki. Inkqubo yokusebenza kwayo kukulayisha ngokuzenzekelayo kunye nokukhulula, kulandelwa unyango lwedangatye, ukuprinta, ukomiswa kwe-UV ye-LED okanye ukomisa umbane we-UV, kwaye ekugqibeleni ukukhulula ngokuzenzekelayo.

1. Ushicilelo oluchanekileyo

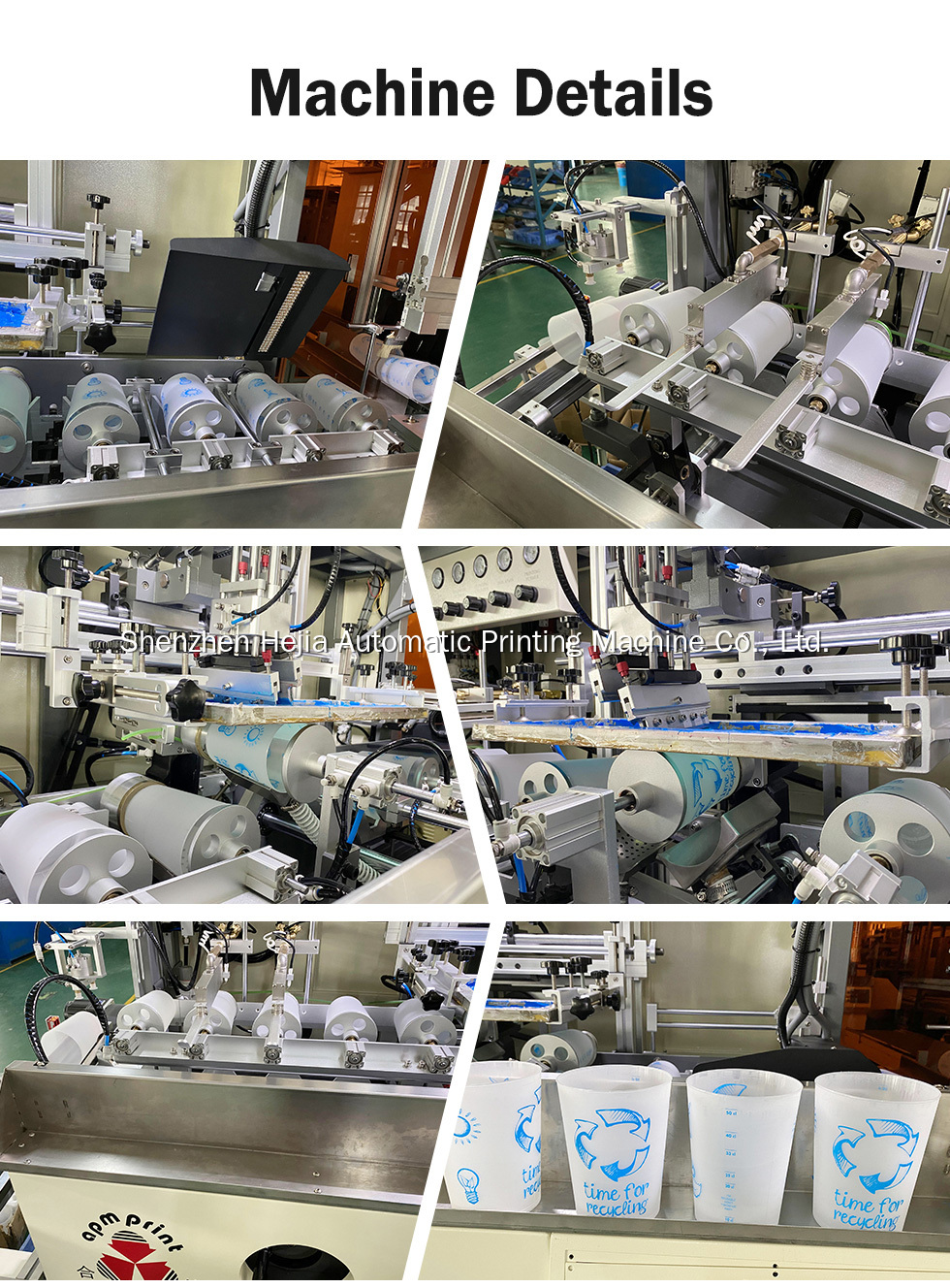

Umatshini wokushicilela weglasi yeglasi yeplastiki usebenzisa iteknoloji yokushicilela isikrini esiphezulu, ngokuchaneka kokuprinta kwe-± 0.1mm, enokubuyisela ngokucacileyo iipatheni eziyinkimbinkimbi kunye neenkcukacha.

2. Iinguqulelo ezininzi

Umatshini wokushicilela wekomityi yeplastiki unokushicilela iikomityi zeplastiki ezinobubanzi obuyi-25 ukuya kwi-100mm kunye nobude obuyi-50 ukuya kwi-280 mm, kwaye ifanelekile kwiindidi zeekomityi eziqhelekileyo.

3. Ukusebenza kakuhle

Isantya soshicilelo somatshini wokushicilela wekomityi yeplastiki yi-2100-2700 iingcezu / iyure, kwaye isantya esiqhelekileyo sisiqhekeza se-2400 / iyure, esinokuhlangabezana nemveliso enkulu.

4. Yomelele kwaye Yomelele

Umzimba womatshini wokuprinta isikrini seglasi yeplastiki wenziwe ngetsimbi ekumgangatho ophezulu, unamandla oxinzelelo olungaphezulu kwe-500MPa kunye nobomi benkonzo yeeyure ezingaphezu kwe-100,000.

Ipharamitha \ltem | S102 1-8 umbala umshicileli screen oluzenzekelayo |

Ubungakanani bomatshini: | 1900x1200x1600mm |

Iyunithi yoshicilelo: | 20-300mm |

Iyunithi yokutya (ukhetho): | 3050x1300x1500mm |

Iyunithi yokukhulula (ukhetho): | 1800x450x750mm |

Amandla: | 380V 3 izigaba 50/60Hz 6.5kw |

1. Ukucoca rhoqo

Emva komsebenzi ngamnye, isikrini, i-scraper, itanki ye-inki, njl. Emva kokuba i-scraper igqibe imisebenzi ye-100 yokushicilela, jonga ukunxiba kwaye ucoce ukuthintela inki eyomileyo ukuba ikhuphe isikrini. Itanki ye-inki kufuneka ikhutshwe kwi-inki eseleyo kwaye icocwe ngokucokisekileyo ukunqanda ukomisa kunye nokuchaphazela ukusetyenziswa okulandelayo.

2. Iindawo zokuthambisa

Iindawo ezihambayo zomatshini wokushicilela weglasi yeglasi yeplastiki kufuneka zithanjiswe kakuhle ukuze kuncitshiswe ukungquzulana nokunxiba. Ukuthambisa ikhonkco lokuhambisa kanye rhoqo kwiiyure ezingama-200 zokusebenza kunokunciphisa izinga lokunxiba nge-50%. Jonga ukuthanjiswa kwegiya phambi kokuba uqalise umatshini qho ngeveki, kwaye ubuyisele igrisi yokuthwala rhoqo emva kweenyanga ezintandathu ukuqinisekisa ukujikeleza okuguquguqukayo.

3. Ukugcinwa kweNkqubo yoMbane

Ubuncinci kanye ngenyanga, jonga ngokupheleleyo isekethe yombane yomatshini wokushicilela wekomityi yeplastiki, ugxininise kwiplagi yamandla, isokhethi, iswitshi, njl. Ibhokisi yokulawula kufuneka ingene kakuhle kwaye ubushushu bube phakathi kwe 20℃ - 35℃.

4. Ukugcinwa kweSkrini

Isikrini somatshini wokushicilela wekomityi yeplastiki sichaphazela umphumo wokushicilela. Yicoce ngoko nangoko emva kokuyisebenzisa kwaye uyigcine ithe tyaba kwindawo eyomileyo nengena umoya ukunqanda ukucudisa nokungqubana. Jonga uxinzelelo rhoqo. Ukunyanzeliswa kwesikrini esitsha kufuneka kugcinwe kwi-20-25N / cm. Yijonge rhoqo amaxesha ali-10 okusetyenziswa. Ukuba i-tension yehla ngaphezu kwe-10%, kufuneka iphinde iqiniswe okanye itshintshwe.

5. Ulungelelwaniso rhoqo

Linganisa indawo yokushicilela rhoqo ngeveki ukuze uqinisekise indawo echanekileyo yepateni. Ukulinganisa uxinzelelo loshicilelo lomatshini wokushicilela wekomityi yeplastiki rhoqo emva kweenyanga ezimbini ukulawula ukuchaneka kobhaliso lwepateni eprintiweyo ngaphakathi ± 0.1mm kunye nokutenxa koxinzelelo loshicilelo ngaphakathi ± 5%

1. Zeziphi iintlobo zeekomityi zeplastiki ezinokuprintwa kumatshini wokushicilela wekomityi yeplastiki?

✅ Umatshini wokushicilela wekomityi yeglasi yeplastiki unokuprinta iindidi zeekomityi zeplastiki, ezinjengeekomityi zamanzi eziqhelekileyo ezilahlwayo ezenziwe ngepolypropylene (Pp) kunye nepolyethene (PE), kunye neekomityi zeti yobisi ezenziwe ngepolystyrene (PS)

2. Zeziphi iindawo zokugcina umatshini wokushicilela wekomityi yeplastiki?

✅ Ukugcinwa kwemihla ngemihla komatshini wokuprinta wekomityi yeplastiki kufuneka kugxininise ekucoceni isikrini nokucoca i-inki eshiyekileyo kwangethuba emva kokusetyenziswa ukunqanda umnatha ekubeni uvaleke kwaye uchaphazele ukuprinta okulandelayo. Jonga ukunxiba kwe-scraper rhoqo kwaye uyibuyisele kwangethuba ukuze uqinisekise ukugquma kwe-inki efanayo. Amalungu omatshini, afana neereyile ezikhokelayo, amatyathanga othumelo, njl.njl., kufuneka athanjiswe rhoqo ukuqinisekisa ukusebenza kakuhle komatshini. ukongeza, inkqubo yesekethe kufuneka kwakhona ihlolwe ukuphepha ukungaphumeleli okubangelwa ukuguga komgca.

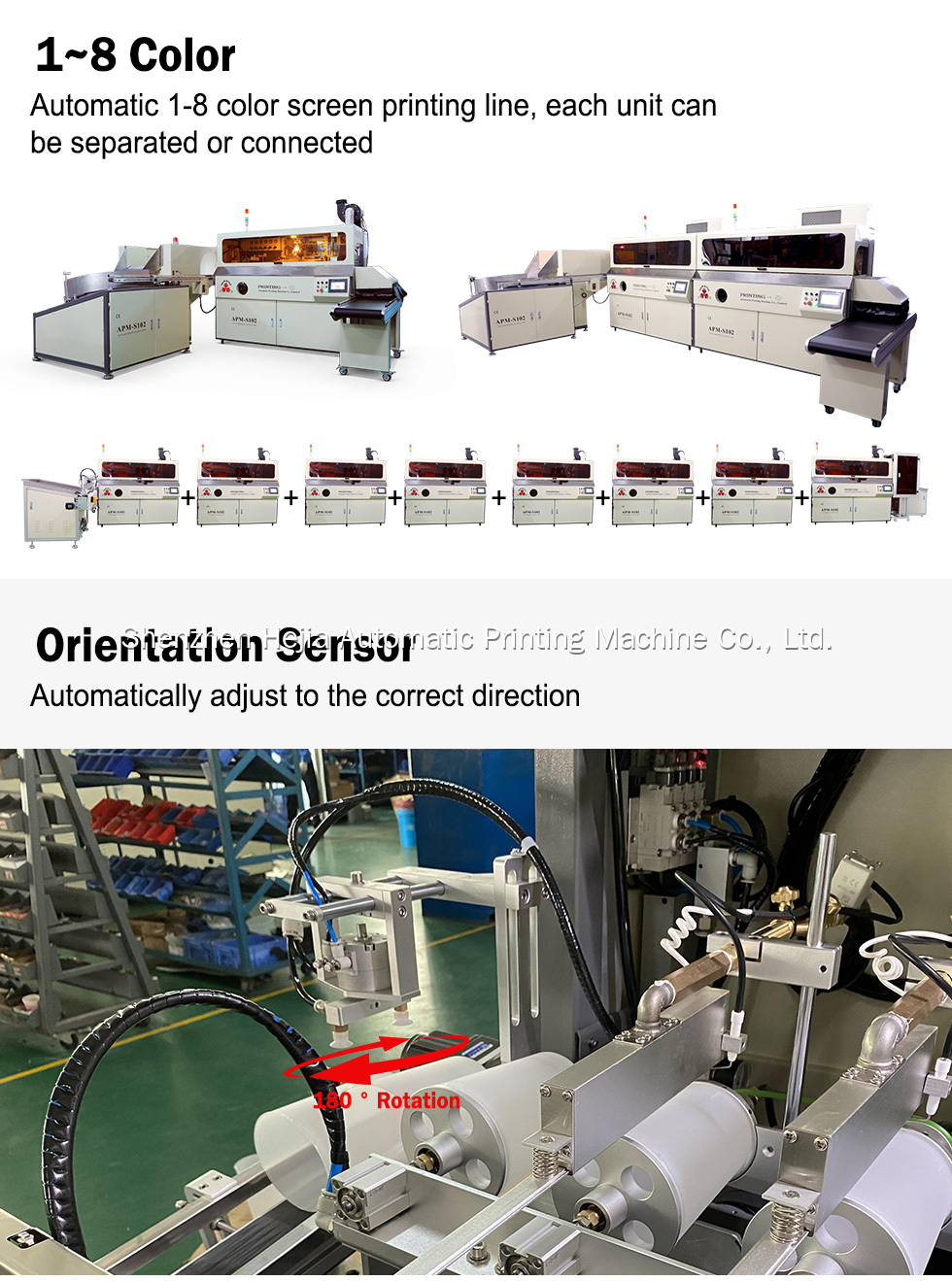

3. Ngaba umatshini wokushicilela wekomityi yeplastiki unokufezekisa ushicilelo olunemibala emininzi?

✅ Umatshini wokushicilela wekomityi yeplastiki unokufezekisa ukuprintwa kwemibala emininzi. Iipateni ezintsonkothileyo zigqitywe ngokuprinta ngokugqithisileyo imibala eyahlukileyo kaninzi. Emva kokuba umbala ngamnye ushicilelwe, kuyimfuneko ukulinda ukuba inki yome okanye usebenzise indlela yokunyanga ngokukhawuleza ngaphambi kokulungelelanisa ngokuchanekileyo umbala olandelayo.

4. Indlela yokulawula ubukhulu be-inki ngexesha lenkqubo yoshicilelo lomatshini wokushicilela weglasi yeplastiki?

✅ Ubukhulu bunokulawulwa ngokulungelelanisa i-angle ye-scraper, uxinzelelo kunye ne-viscosity ye-inki. Xa i-angle ye-scraper incinci kwaye uxinzelelo luphezulu, ubukhulu be-inki buncinci; kungenjalo, ingqindilili. I-viscosity ye-inki iphezulu kwaye ubukhulu buyanda. Ubungqingqwa be-inki obufanelekileyo bunokuqinisekisa ukuba ipateni igcwele umbala kwaye isantya sokumisa sifanelekile, ukuthintela iingxaki ezinjengokuqokelelwa kwe-inki kunye nokufa okucothayo ngenxa yobunzima obugqithisileyo, okanye umbala ongaxutywanga kunye namandla angonelanga okugquma ngenxa yokubhitya okugqithisileyo.

5. Ziziphi iimfuno zendawo yokusebenza yomatshini wokuprinta isikrini seglasi yeplastiki

✅ Indawo yokusebenza yomatshini wokushicilela wekomityi yeplastiki kufuneka igcinwe icocekile, yomile kwaye ingena umoya. Uthuli oluninzi lunokuxutywa kwi-inki kwaye luchaphazele umgangatho woshicilelo. Indawo efumileyo inokutshintsha ukusebenza kwe-inki okanye iruse iindawo zomatshini. Uluhlu olufanelekileyo lobushushu lukholisa ukuba ngama-20-25'c. Ukushisa okuphezulu kakhulu okanye okuphantsi kakhulu kunokuchaphazela umbane kunye nesantya sokuqhuba i-inki, i-Ventilation inceda iphunga le-inki ukuba lihlakazwe kwaye igesi ikhutshwe ngexesha lokumisa.

6. Ingaba umatshini wokushicilela wekomityi yeplastiki unokuprinta kumphezulu wekomityi yeplastiki egobileyo?

✅ Umatshini wokushicilela wekomityi yeplastiki unokuprinta kumphezulu wekomityi yeplastiki egobileyo. t ixhotyiswe ngesixhobo esikhethekileyo okanye i-tumble enokuthi ilungise kwaye ijikeleze ikomityi ukwenzela ukuba ipleyiti yesikrini kunye nomphezulu wekomityi igcine i-angle yoqhagamshelwano efanelekileyo kunye noxinzelelo ngexesha lokushicilela. Ngokulungelelanisa ezi zixhobo, iyakwazi ukuziqhelanisa neekomityi zee-curvatures ezahlukeneyo, iqinisekise ukuba i-inki ifakwe ngokulinganayo kumphezulu womzimba wendebe, kwaye ifezekise ukuprintwa kwepateni epheleleyo kunye ecacileyo.

📩 Qhagamshelana nathi namhlanje ukufumana isisombululo esilungiselelwe iimfuno zakho zemveliso! 🚀

UAlice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Ifeksi: +86 - 755 - 2672 3710

Iselula: +86 - 181 0027 6886

I-imeyile: sales@apmprinter.com

What sapp: 0086 -181 0027 6886