Plastic cup screen printing machine

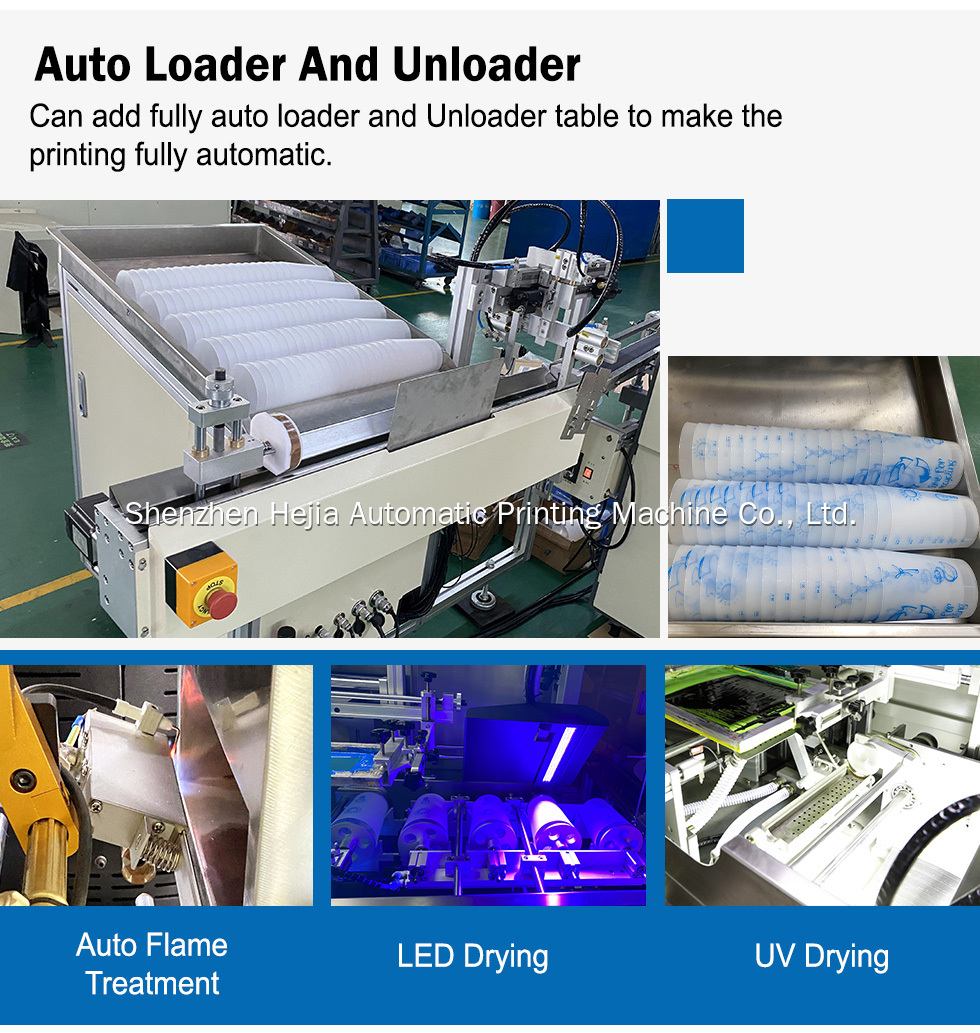

Introduction The S102C Plastic cup screen printing machine is a printing device designed for round or curved objects such as plastic cups. Its working process is automatic loading and unloading, followed by flame treatment, printing, LED UV drying or electric UV drying, and finally automatic...

S102C Plastic cup screen printing machine is a printing device designed for round or curved objects such as plastic cups. Its working process is automatic loading and unloading, followed by flame treatment, printing, LED UV drying or electric UV drying, and finally automatic unloading.

1. Precision Printing

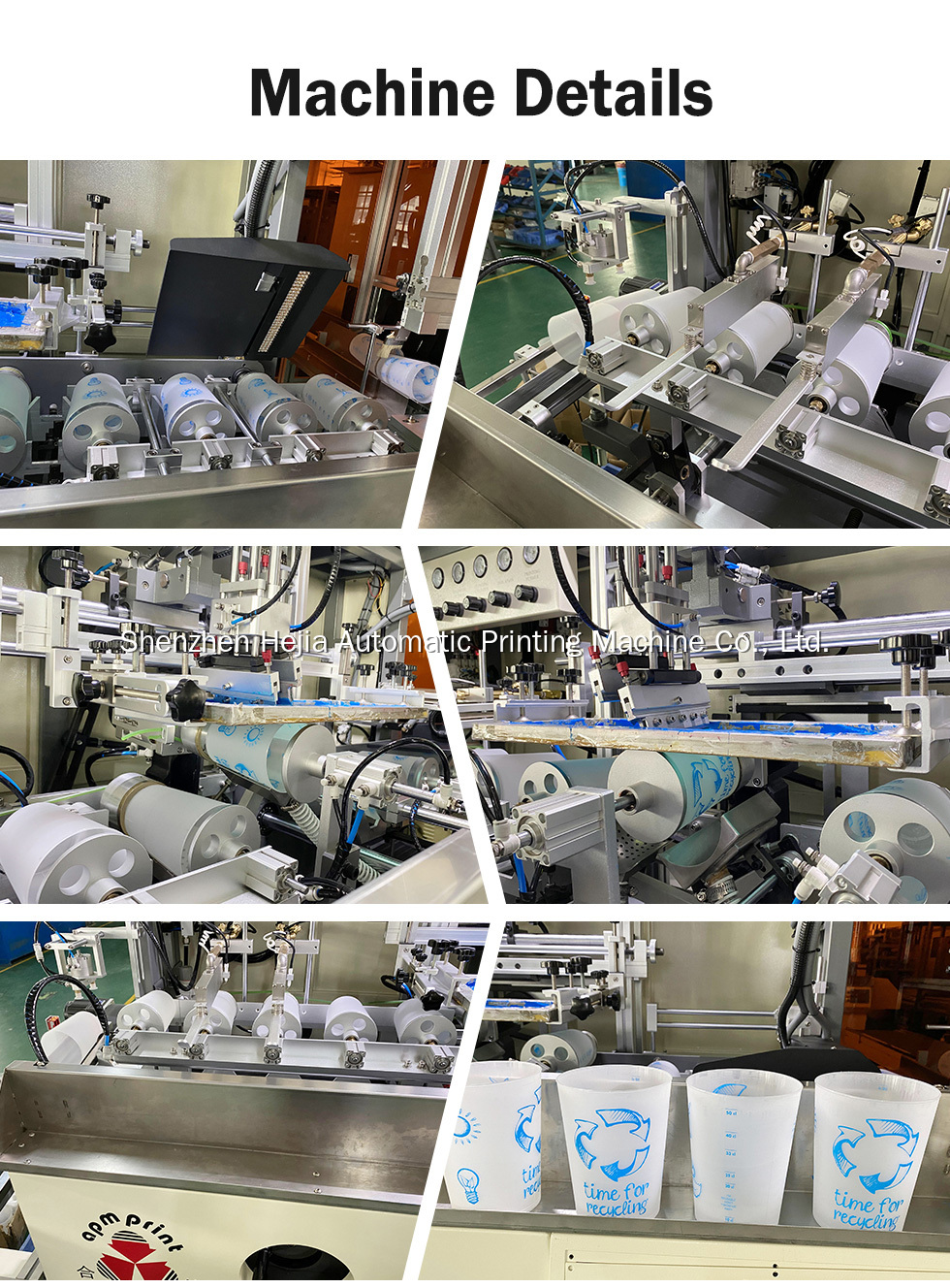

The plastic cup screen printing machine uses high-precision screen printing technology, with a printing accuracy of ±0.1mm, which can clearly restore complex patterns and details.

2. Multiple Adaptations

The plastic cup screen printing machine can print plastic cups with diameters of 25 to 100mm and lengths of 50 to 280 mm, and is suitable for a variety of common cup sizes.

3. Efficiency

The printing speed of the plastic cup screen printing machine is 2100-2700 pieces/hour, and the normal speed is 2400 pieces/hour, which can meet large-scale production.

4. Sturdy And Durable

The body of the plastic cup screen printing machine is made of high-quality steel, with a compressive strength of more than 500MPa and a service life of more than 100,000 hours.

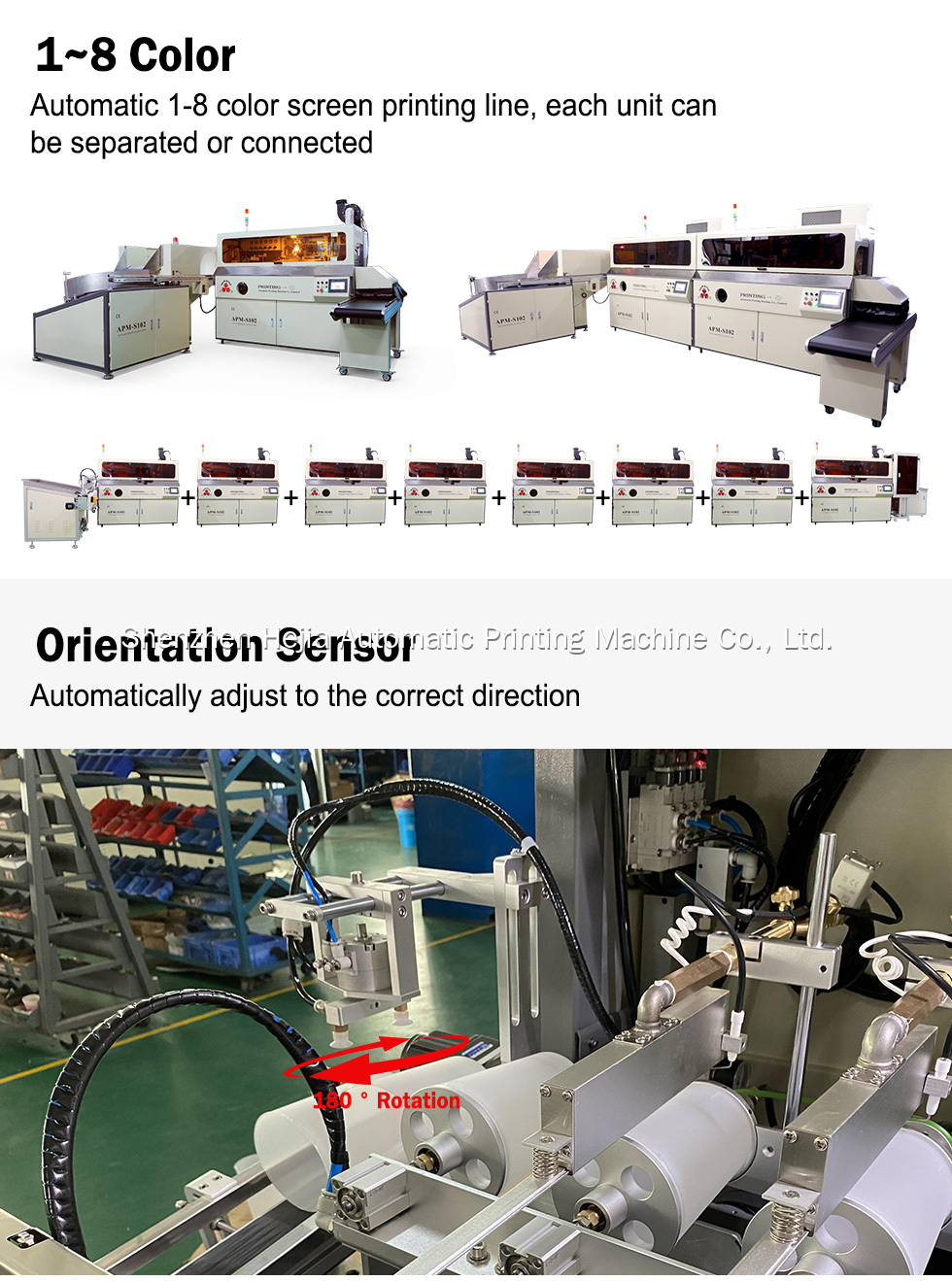

Parameter \ltem | S102 1-8 color automatic screen printer |

Machine Dimension: | 1900x1200x1600mm |

Printing unit: | 20-300mm |

Feeding unit (optional): | 3050x1300x1500mm |

Unloading unit (optional): | 1800x450x750mm |

Power: | 380V 3 phases 50/60Hz 6.5kw |

1. Regular Cleaning

After each work, the screen, scraper, ink tank, etc. of the plastic cup screen printing machine need to be carefully cleaned with a special cleaning agent. After the scraper completes 100 printing operations, check the wear and clean it to prevent the dried ink from scratching the screen. The ink tank needs to be emptied of the remaining ink and thoroughly cleaned to avoid drying and affecting the next use.

2. Parts Lubrication

The moving parts of the plastic cup screen printing machine need to be well-lubricated to reduce friction and wear. Lubricating the transmission chain once every 200 hours of operation can reduce the wear rate by 50%. Check the gear lubrication before starting the machine every week, and replace the grease of the bearing every six months to ensure flexible rotation.

3. Electrical System Maintenance

At least once a month, fully check the electrical circuit of the plastic cup screen printing machine, focusing on the power plug, socket, switch, etc. to prevent short circuits or fires caused by poor contact. The control box should be well-ventilated and the temperature should be between 20℃ - 35℃.

4. Screen Maintenance

The screen of the plastic cup screen printing machine affects the printing effect. Clean it immediately after use and store it flat in a dry and ventilated place to avoid squeezing and collision. Check the tension regularly. The tension of the new screen should be kept at 20-25N/cm. Check it every 10 times of use. If the tension drops by more than 10%, it needs to be re-tightened or replaced.

5. Regular Calibration

Calibrate the printing position every week to ensure the accurate position of the pattern. Calibrate the printing pressure of the plastic cup screen printing machine every two months to control the registration accuracy of the printed pattern within ±0.1mm and the printing pressure deviation within ±5%

1. What types of plastic cups can the plastic cup screen printing machine print?

✅ The plastic cup screen printing machine can print a variety of plastic cups, such as the common disposable water cups made of polypropylene(Pp) and polyethene(PE), and milk tea cups made of polystyrene (PS)

2. What are the maintenance points of the plastic cup screen printing machine?

✅ The daily maintenance of the plastic cup screen printing machine should focus on cleaning the screen and cleaning the residual ink in time after use to prevent the mesh from clogging and affecting the next printing. Check the scraper wear regularly and replace it in time to ensure uniform ink coating. Mechanical parts, such as guide rails, transmission chains, etc., need to be lubricated regularly to ensure the machine's smooth operation. in addition, the circuit system should also be checked to avoid failures caused by the ageing of the line.

3. Can the plastic cup screen printing machine achieve multi-colour printing?

✅ The plastic cup screen printing machine can achieve multicolour printing. Complex patterns are completed by overprinting different colours multiple times. After each colour is printed, it is necessary to wait for the ink to dry or use a quick curing method before accurately aligning the next colour.

4. How to control the ink thickness during the printing process of the plastic cup screen printing machine?

✅ The thickness can be controlled by adjusting the scraper angle, pressure and ink viscosity. When the scraper angle is small and the pressure is high, the ink thickness is relatively thin; otherwise, it is thick. The ink viscosity is high and the thickness increases. The appropriate ink thickness can ensure that the pattern is full of colour and the drying speed is reasonable, avoiding problems such as ink accumulation and slow dying due to excessive thickness, or unsaturated colour and insufficient covering power due to excessive thinness.

5. What are the requirements for the working environment of the plastic cup screen printing machine

✅ The working environment of the plastic cup screen printing machine should be kept clean, dry and well-ventilated. Too much dust may mix into the ink and affect printing quality. A humid environment may change the ink performance or rust the machine parts. The suitable temperature range is generally 20-25'c. Too high or too low temperature may affect the fluidity and driving speed of the ink, Ventilation helps the ink smell to be dispersed and the gas to be discharged during the drying process.

6. Can the plastic cup screen printing machine print on the surface of a curved plastic cup?

✅ The plastic cup screen printing machine can print on the surface of a curved plastic cup. t is equipped with a special fixture or tumble that can fix and rotate the cup so that the screen plate and the cup surface maintain a suitable contact angle and pressure during printing. By adjusting these devices, it can adapt to cups of different curvatures, ensure that the ink is evenly attached to the surface of the cup body, and achieve complete and clear pattern printing.

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886