Umshini wokunyathelisa wesikrini senkomishi yepulasitiki

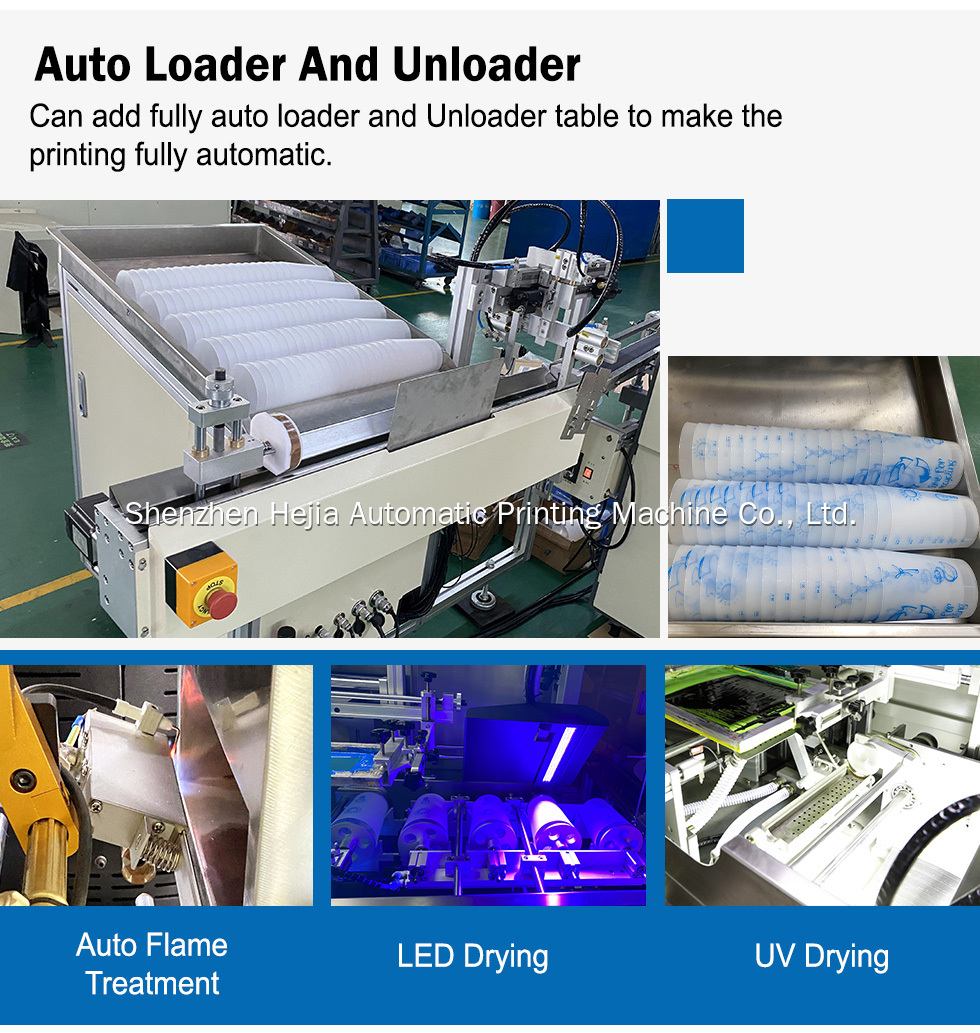

Isingeniso Umshini wokunyathelisa wesikrini senkomishi ye-Plastiki ye-S102C iyithuluzi lokunyathelisa eliklanyelwe izinto eziyindilinga noma ezigobile njengezinkomishi zepulasitiki. Inqubo yayo yokusebenza iwukulayisha nokuthulula okuzenzakalelayo, kulandelwa ukwelashwa kwelangabi, ukuphrinta, ukomiswa kwe-LED UV noma ukomiswa kwe-UV kagesi, futhi ekugcineni okuzenzakalelayo...

Umshini wokunyathelisa wesikrini senkomishi ye-S102C iyithuluzi lokunyathelisa eliklanyelwe izinto eziyindilinga noma ezigobile njengezinkomishi zepulasitiki. Inqubo yayo yokusebenza iwukulayisha nokuthulula okuzenzakalelayo, kulandelwe ukwelashwa kwelangabi, ukuphrinta, ukomiswa kwe-LED UV noma ukomiswa kwe-UV kagesi, futhi ekugcineni ukuthulula okuzenzakalelayo.

1. Ukuphrinta Okunembe

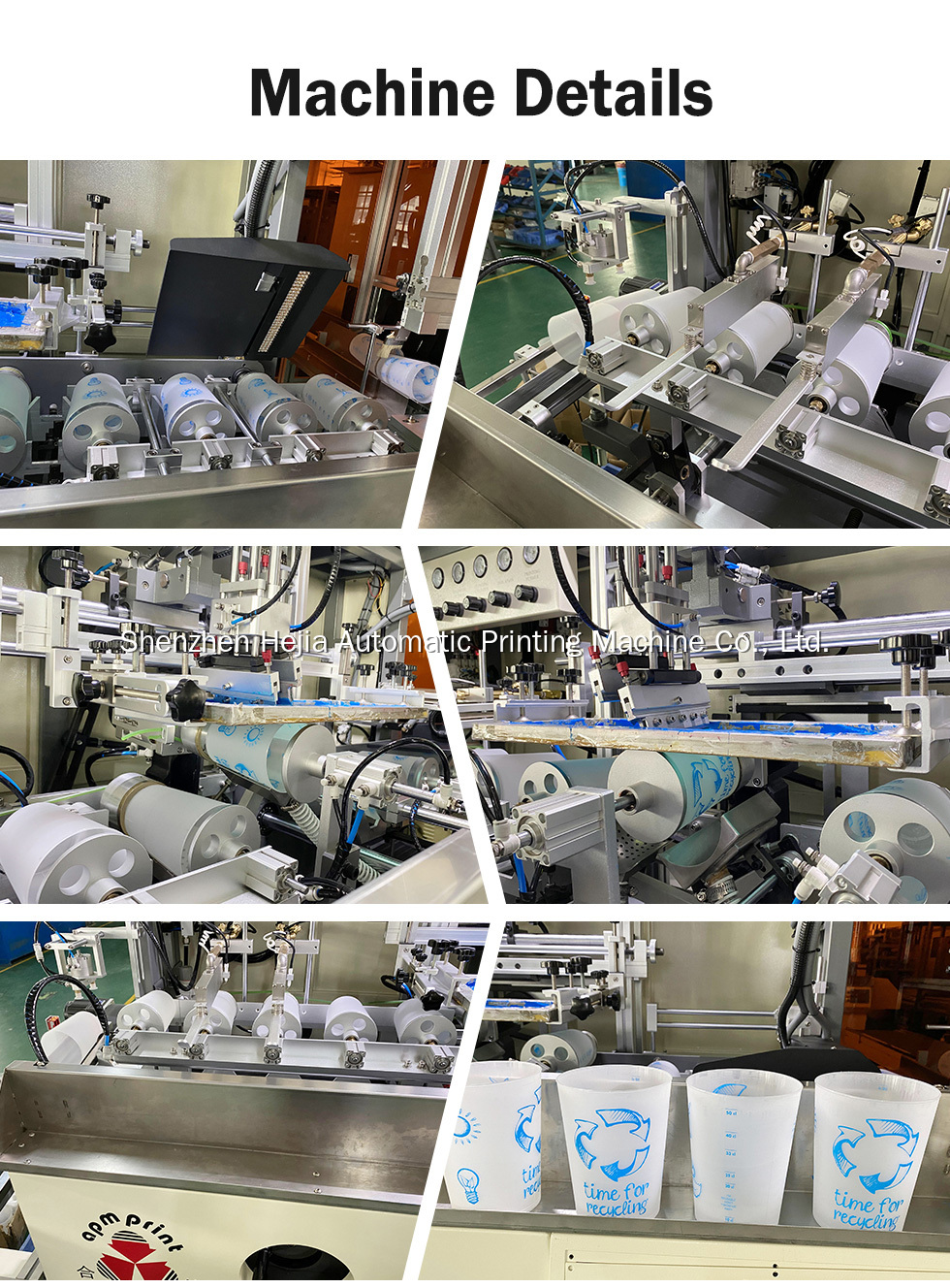

Umshini wokunyathelisa isikrini senkomishi yepulasitiki usebenzisa ubuchwepheshe bokuphrinta besikrini obunembayo, ngokunemba kokuphrinta okungu-±0.1mm, okungabuyisela ngokucacile amaphethini ayinkimbinkimbi nemininingwane.

2. Ukuzijwayeza Okuningi

Umshini wokunyathelisa wesikrini senkomishi yepulasitiki ungaphrinta izinkomishi zepulasitiki ezinobubanzi obungu-25 kuya ku-100mm nobude obungu-50 kuya ku-280 mm, futhi ulungele izinhlobonhlobo zamasayizi ezinkomishi ezivamile.

3. Ukusebenza kahle

Ijubane lokuphrinta lomshini wokunyathelisa wesikrini senkomishi yepulasitiki yizicucu ezingu-2100-2700/ihora, futhi isivinini esivamile singama-2400 izingcezu/ihora, esingahlangabezana nokukhiqizwa okukhulu.

4. Iqinile Futhi Ihlala Njalo

Umzimba womshini wokunyathelisa wesikrini senkomishi yepulasitiki wenziwe ngensimbi yezinga eliphezulu, enamandla acindezelayo angaphezu kuka-500MPa nempilo yesevisi engaphezu kwamahora angu-100,000.

Ipharamitha \ltem | Iphrinta yesikrini esizenzakalelayo ye-S102 1-8 |

Ubukhulu bomshini: | 1900x1200x1600mm |

Iyunithi yokuphrinta: | 20-300 mm |

Iyunithi yokudla (ongakukhetha): | 3050x1300x1500mm |

Iyunithi yokulayisha (kuyakhetheka): | 1800x450x750mm |

Amandla: | 380V 3 izigaba 50/60Hz 6.5kw |

1. Ukuhlanza Njalo

Ngemuva komsebenzi ngamunye, isikrini, i-scraper, ithangi likayinki, njll. yomshini wokunyathelisa isikrini senkomishi yepulasitiki kudingeka ihlanzwe ngokucophelela nge-ejenti yokuhlanza ekhethekile. Ngemuva kokuthi i-scraper iqedele imisebenzi yokuphrinta eyi-100, hlola ukuguga futhi uyihlanze ukuze uvimbele u-inki omisiwe ukuthi anganwaya isikrini. Ithangi likayinki lidinga ukuthululwa ku-inki osele futhi lihlanzwe kahle ukuze kugwenywe ukomiswa nokuba nomthelela ekusebenziseni okulandelayo.

2. Izingxenye Ukugcotshwa

Izingxenye ezihambayo zomshini wokunyathelisa isikrini senkomishi yepulasitiki zidinga ukugcotshwa kahle ukuze kuncishiswe ukungqubuzana nokuguga. Ukugcoba iketango lokudlulisela kanye njalo emahoreni angama-200 okusebenza kunganciphisa izinga lokuguga ngo-50%. Hlola ukugcotshwa kwegiya ngaphambi kokuqala umshini masonto onke, bese ushintsha igrisi yebheringi njalo ngemva kwezinyanga eziyisithupha ukuze uqinisekise ukuphenduka okuvumelana nezimo.

3. Ukugcinwa Kwesistimu Kagesi

Okungenani kanye ngenyanga, hlola ngokugcwele isekethe kagesi yomshini wokunyathelisa wesikrini senkomishi yepulasitiki, ugxile kupulaki yamandla, isokhethi, ukushintsha, njll. ukuze uvimbele amasekhethi amafushane noma imililo ebangelwa ukuthintana kabi. Ibhokisi lokulawula kufanele libe nomoya omuhle futhi izinga lokushisa kufanele libe phakathi kuka-20℃ - 35℃.

4. Ukugcinwa Kwesikrini

Isikrini somshini wokunyathelisa wesikrini senkomishi yepulasitiki sithinta umphumela wokuphrinta. Ihlanze ngokushesha ngemva kokuyisebenzisa futhi uyibeke endaweni eyomile futhi engenawo umoya ukuze ugweme ukuminya nokungqubuzana. Hlola ukushuba njalo. Ukuqina kwesikrini esisha kufanele kugcinwe ku-20-25N/cm. Kuhlole njalo izikhathi ezingu-10 zokusebenzisa. Uma ukungezwani kwehla ngaphezu kuka-10%, kufanele kuqiniswe kabusha noma kushintshwe.

5. Ukulinganisa Okuvamile

Linganisa indawo yokuphrinta masonto onke ukuze uqinisekise ukuma okunembile kwephethini. Linganisa ingcindezi yokuphrinta yomshini wokunyathelisa wesikrini senkomishi yepulasitiki njalo ngemva kwezinyanga ezimbili ukuze ulawule ukunemba kokubhaliswa kwephethini ephrintiwe ngaphakathi kuka-±0.1mm kanye nokuchezuka kwengcindezi yokuphrinta ngaphakathi kuka-±5%

1. Yiziphi izinhlobo zezinkomishi zepulasitiki umshini wokunyathelisa wenkomishi yepulasitiki ongaphrinta?

✅ Umshini wokunyathelisa wesikrini senkomishi yepulasitiki ungaphrinta izinkomishi zepulasitiki ezihlukahlukene, njengezinkomishi zamanzi ezilahlwayo ezivamile ezenziwe nge-polypropylene(Pp) ne-polyethene(PE), nezinkomishi zetiye lobisi ezenziwe nge-polystyrene (PS)

2. Yiziphi amaphuzu okunakekela omshini wokunyathelisa wesikrini senkomishi yepulasitiki?

✅ Ukugcinwa kwansuku zonke komshini wokunyathelisa wesikrini senkomishi yepulasitiki kufanele kugxile ekuhlanzeni isikrini nokuhlanza uyinki osele ngesikhathi ngemva kokusetshenziswa ukuze kuvinjwe inetha ukuthi livaleke futhi lithinte ukuphrinta okulandelayo. Hlola ukugqokwa kwe-scraper njalo futhi ubeke esikhundleni ngesikhathi ukuze uqinisekise ukunamathela kwe-inki efanayo. Izingxenye zemishini, njengama-guide rails, amaketanga okuhambisa, njll., zidinga ukugcotshwa njalo ukuze kuqinisekiswe ukusebenza kahle komshini. ngaphezu kwalokho, uhlelo lwesifunda kufanele futhi luhlolwe ukugwema ukwehluleka okubangelwa ukuguga komugqa.

3. Ingabe umshini wokunyathelisa wesikrini senkomishi yepulasitiki ungafinyelela ukuphrinta ngemibala eminingi?

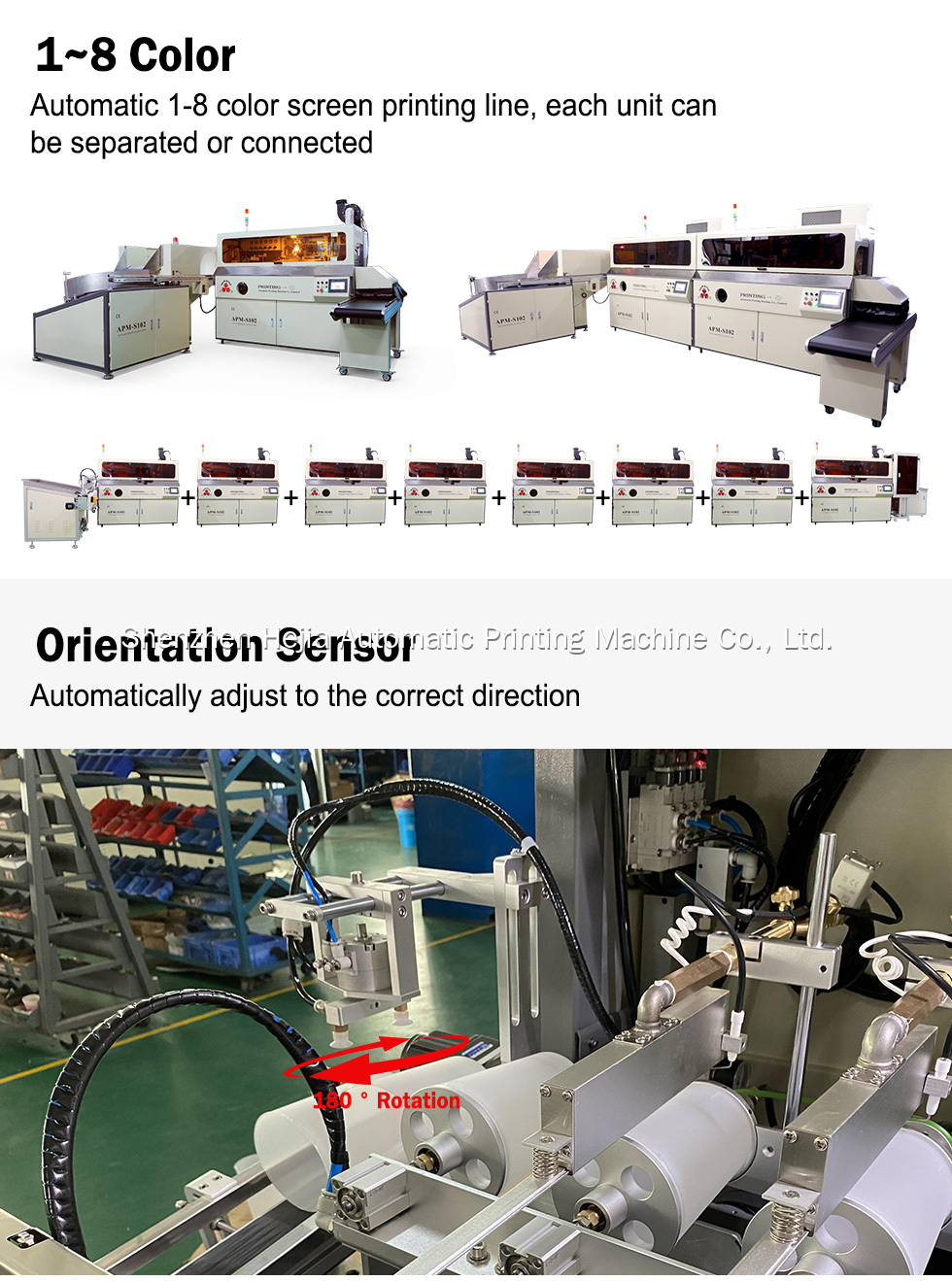

✅ Umshini wokuphrinta wesikrini senkomishi yepulasitiki ungafinyelela ukuphrinta ngemibala eminingi. Amaphethini ayinkimbinkimbi aqedwa ngokuphrinta imibala ehlukene izikhathi eziningi. Ngemuva kokuthi umbala ngamunye uphrintiwe, kuyadingeka ukuthi ulinde uyinki ukuthi wome noma usebenzise indlela yokwelapha esheshayo ngaphambi kokuqondanisa ngokunembile umbala olandelayo.

4. Indlela yokulawula ukujiya kweyinki phakathi nenqubo yokuphrinta yomshini wokunyathelisa wesikrini senkomishi yepulasitiki?

✅ Ubukhulu bungalawulwa ngokulungisa i-angle ye-scraper, ingcindezi kanye ne-viscosity ye-inki. Lapho i-engeli ye-scraper incane futhi ingcindezi iphezulu, ubukhulu beyinki buncane; kungenjalo, iwugqinsi. I-viscosity ye-inki iphezulu futhi ukushuba kuyanda. Ugqinsi lukayinki olufanele lungaqinisekisa ukuthi iphethini igcwele umbala kanye nesivinini sokumisa sinengqondo, kugwenywe izinkinga ezinjengokuqoqwa kukayinki nokufa kancane ngenxa yogqinsi oludlulele, noma umbala ongagcwele kanye namandla okuvala anganele ngenxa yokuba mncane kakhulu.

5. Yiziphi izidingo zendawo yokusebenza yomshini wokunyathelisa isikrini senkomishi yepulasitiki

✅ Indawo yokusebenza yomshini wokunyathelisa wesikrini senkomishi yepulasitiki kufanele igcinwe ihlanzekile, yomile futhi inomoya omuhle. Uthuli oluningi lungase luxube kuyinki futhi luthinte ikhwalithi yokuphrinta. Indawo enomswakama ingase iguqule ukusebenza kweyinki noma igxume izingxenye zomshini. Izinga lokushisa elifanele livamise ukuba ngu-20-25'c. Ukushisa okuphezulu kakhulu noma okuphansi kakhulu kungase kuthinte ukugeleza kwamanzi kanye nesivinini sokushayela sikayinki, Ukungenisa umoya kusiza iphunga likayinki ukuba lihlakazeke kanye negesi ukuthi ikhishwe phakathi nenqubo yokomisa.

6. Ingabe umshini wokunyathelisa wesikrini senkomishi yepulasitiki ungaphrinta phezu kwenkomishi yepulasitiki egobile?

✅ Umshini wokunyathelisa wesikrini senkomishi yepulasitiki ungaphrinta phezu kwenkomishi yepulasitiki egobile. t ifakwe isici esikhethekile noma i-wamble engalungisa futhi izungezise inkomishi ukuze ipuleti lesikrini nendawo yenkomishi igcine i-engeli yokuxhumana efanelekile kanye nokucindezela ngesikhathi sokuphrinta. Ngokulungisa le mishini, ingakwazi ukuzivumelanisa nezindebe zama-curvature ahlukene, iqinisekise ukuthi uyinki unamathiselwe ngokulinganayo ebusweni bomzimba wendebe, futhi ifinyelele ukuphrinta kwephethini okuphelele nokucacile.

📩 Xhumana nathi namuhla ukuze uthole isixazululo esenziwe ngokwezifiso esifanelana nezidingo zakho zokukhiqiza! 🚀

U-Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Ifeksi: +86 - 755 - 2672 3710

Iselula: +86 - 181 0027 6886

I-imeyili: sales@apmprinter.com

Whatsap: 0086 -181 0027 6886