Glass Bottle Coating Line Introduction

The Glass Bottle Coating Line is an advanced automatic system designed for coating a wide range of bottles including glass bottles, wine bottles, perfume bottles, ceramic jars, cosmetic containers, and tea canisters. This line incorporates cutting-edge UV painting technology that ensures a uniform, high-quality finish for products in various industries, including cosmetics, beverages, and luxury goods. The Glass Bottle Painting Line is engineered to meet the growing demands of both high-volume production and precision coatings.

This automated solution streamlines the coating process, enhancing both efficiency and product quality while offering versatile compatibility with various materials and bottle types.

Key Features of Glass Bottle Coating Line

Versatile Coating Application – The Glass Bottle Coating Line can handle a variety of containers including glass bottles, wine bottles, perfume bottles, cosmetic jars, tea canisters, and ceramic bottles. Whether it’s a delicate glass bottle or a more robust ceramic jar, the system adapts easily to different shapes and sizes.

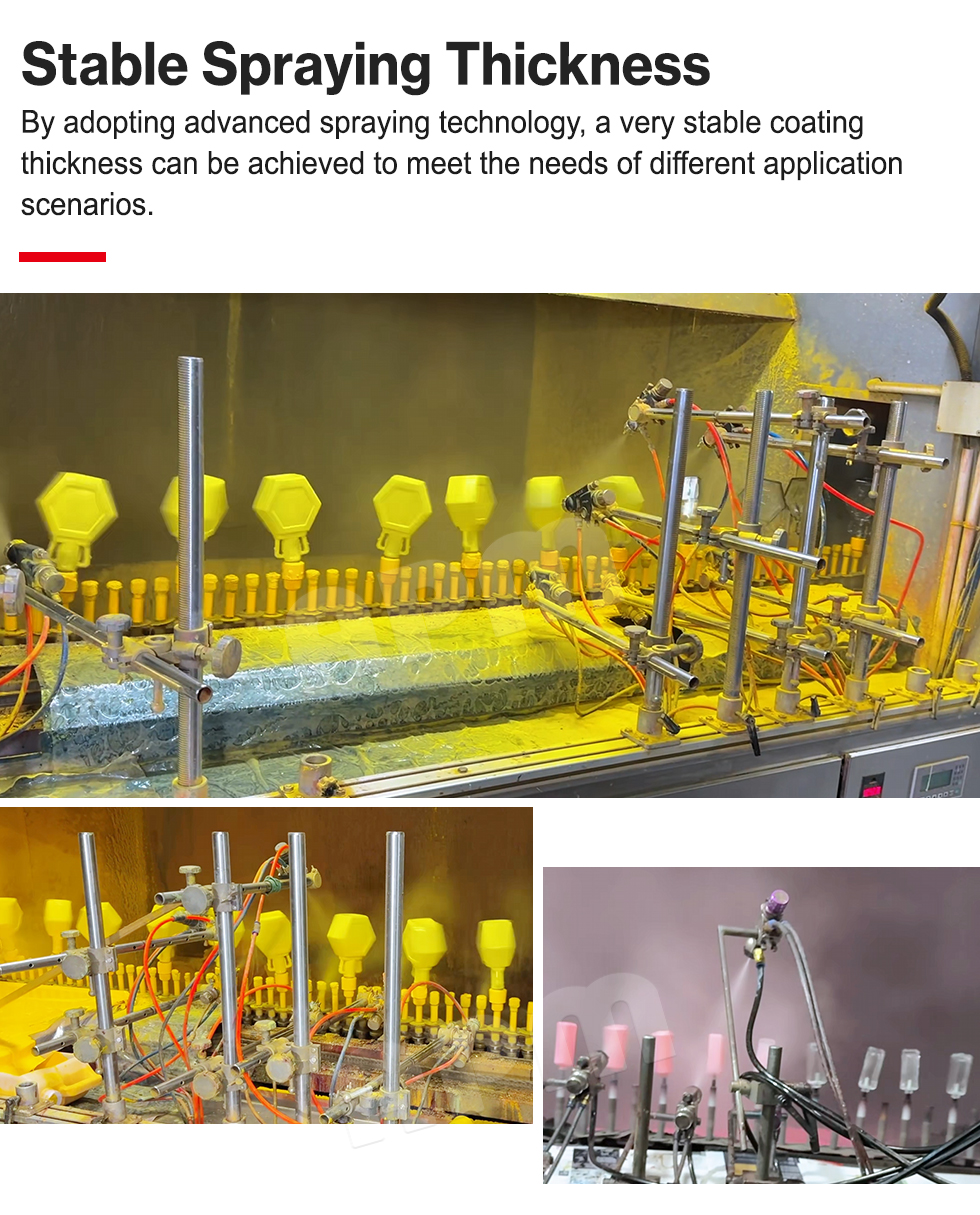

UV Coating Technology – This line utilizes UV coating technology, which ensures fast curing and a durable finish. The UV light used in the system helps the paint cure almost instantly, reducing drying time and improving production speed.

Automatic Precision Control – With intelligent PLC control and touchscreen operation, the Glass Bottle Painting Line guarantees precise control over parameters like coating thickness, spray pattern, and curing time. This automated control results in consistently high-quality output with minimal human intervention.

Energy-Efficient & Environmentally Friendly – The system is designed to be energy-efficient, utilizing advanced drying technologies that minimize energy consumption. The environmentally friendly UV curing process emits no harmful VOCs, contributing to a cleaner and safer production environment.

High-Speed Production – The Glass Bottle Coating Line operates at high speeds, making it perfect for large-scale production. Whether you’re working with standard glass bottles or more intricate packaging like perfume bottles or cosmetic containers, the line ensures fast processing with excellent finish quality.

Durability & Maintenance – Made with high-quality materials such as 304 stainless steel and high-temperature resistant components, this line is built for long-term use. Its robust construction guarantees reliable performance, even in high-demand environments. The system’s easy maintenance design ensures minimal downtime and longer machine life.

Glass Bottle Coating Line Products & Parameters

| Specification/Features | |

|---|---|

| Main Material | Suitable for Glass, Ceramic, and Metal Bottles |

| Coating Type | UV Coating, Eco-friendly, Fast-drying |

| Control System | PLC + Touch Screen |

| Temperature Range | Room Temperature to 100°C |

| Max Bottle Height | Customizable based on customer requirements |

| Max Bottle Diameter | Customizable based on customer requirements |

| Production Capacity | Up to 300 pieces per minute |

| Power Supply | Standard 380V or Custom as required |

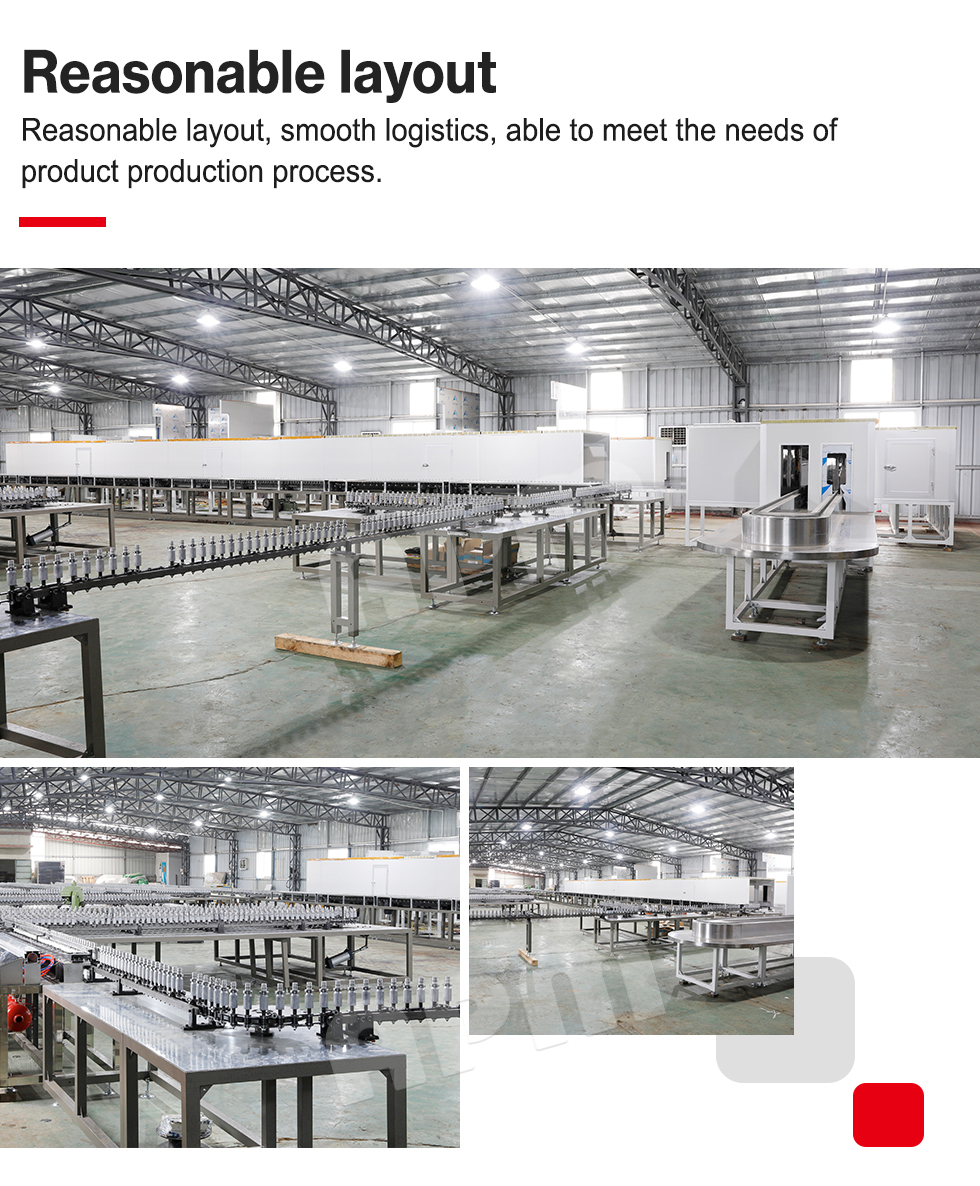

| Dimensions | Customizable to fit factory space and production requirements |

| Drying System | High-efficiency UV Lamp Curing System |

| Automation | Fully automated, low labor costs |

Glass Bottle Coating Line Maintenance

1. Regular Cleaning: Ensure that the spray guns, UV curing lamps, and conveyors are cleaned regularly to prevent clogging and to maintain uniform coating quality.

2. Lubrication: Apply appropriate lubrication to moving parts such as conveyors and rotating arms to reduce friction and ensure smooth operation.

3. UV Lamp Replacement: Check the UV lamps periodically for optimal curing performance. Replace lamps as per the manufacturer’s recommendation to ensure consistent coating results.

4. Electrical and Air System Checks: Regularly inspect the electrical system and air pressure for any leaks or wear to avoid disruptions in the coating process.

5. Component Inspection: Regular inspection of key components, such as spray nozzles, heaters, and control panels, will help to identify any early signs of wear and prevent costly repairs.

- FAQ

Q1: Can the Glass Bottle Coating Line handle bottles of different shapes and sizes?

A1: Yes, this line is highly versatile and can handle glass bottles, wine bottles, perfume bottles, ceramic jars, cosmetic containers, and tea canisters of various shapes and sizes. Custom fixtures and jigs can be added to accommodate specific shapes.

Q2: What type of coating does the Glass Bottle Coating Line use?

A2: The line uses UV coating technology, which provides fast curing, long-lasting durability, and an environmentally friendly solution. The UV coating ensures a high-quality finish while reducing drying time.

Q3: Is this line energy-efficient?

A3: Yes, the Glass Bottle Coating Line is designed with energy efficiency in mind. The UV curing process is highly effective, reducing the need for excessive energy consumption. The system’s components are also designed for long-term use, ensuring minimal energy waste.

Q4: How fast is the production capacity of this line?

A4: The Glass Bottle Coating Line can process up to 300 bottles per minute, depending on the bottle size and coating requirements. This makes it ideal for high-volume production environments.

Q5: What is the warranty and maintenance policy for this product?

A5: The Glass Bottle Coating Line comes with a one-year warranty for normal usage. This warranty covers free replacement of damaged components, except consumables. After the warranty period, we offer ongoing support with affordable maintenance services.