Automatic Robot Spray Painting Line Coating Line Plant Powder Coating Production Line For Metal And Plastic Parts

Our Automatic Robot Spray Painting Line is a high-efficiency, fully automated coating system designed for metal and plastic parts. It integrates robotic precision, multi-angle spraying, and intelligent control systems, ensuring uniform coating, high-quality finishes, and minimal material waste.

This versatile production line supports both liquid spray painting and powder coating, making it ideal for automotive parts, electronics, home appliances, and industrial components. With CNC & PLC control, servo-driven reciprocators, and customizable spraying programs, it enhances production efficiency, reduces labor costs, and ensures eco-friendly operation.

Our Automatic Robot Spray Painting Line is a high-efficiency coating solution designed for metal and plastic parts. It integrates robotic spraying technology, UV curing, and powder coating processes, ensuring superior surface finishing, durability, and material utilization. This fully automated system enhances production efficiency, reduces waste, and ensures a consistent, high-quality coating.

1. Advanced Robotic Spraying System

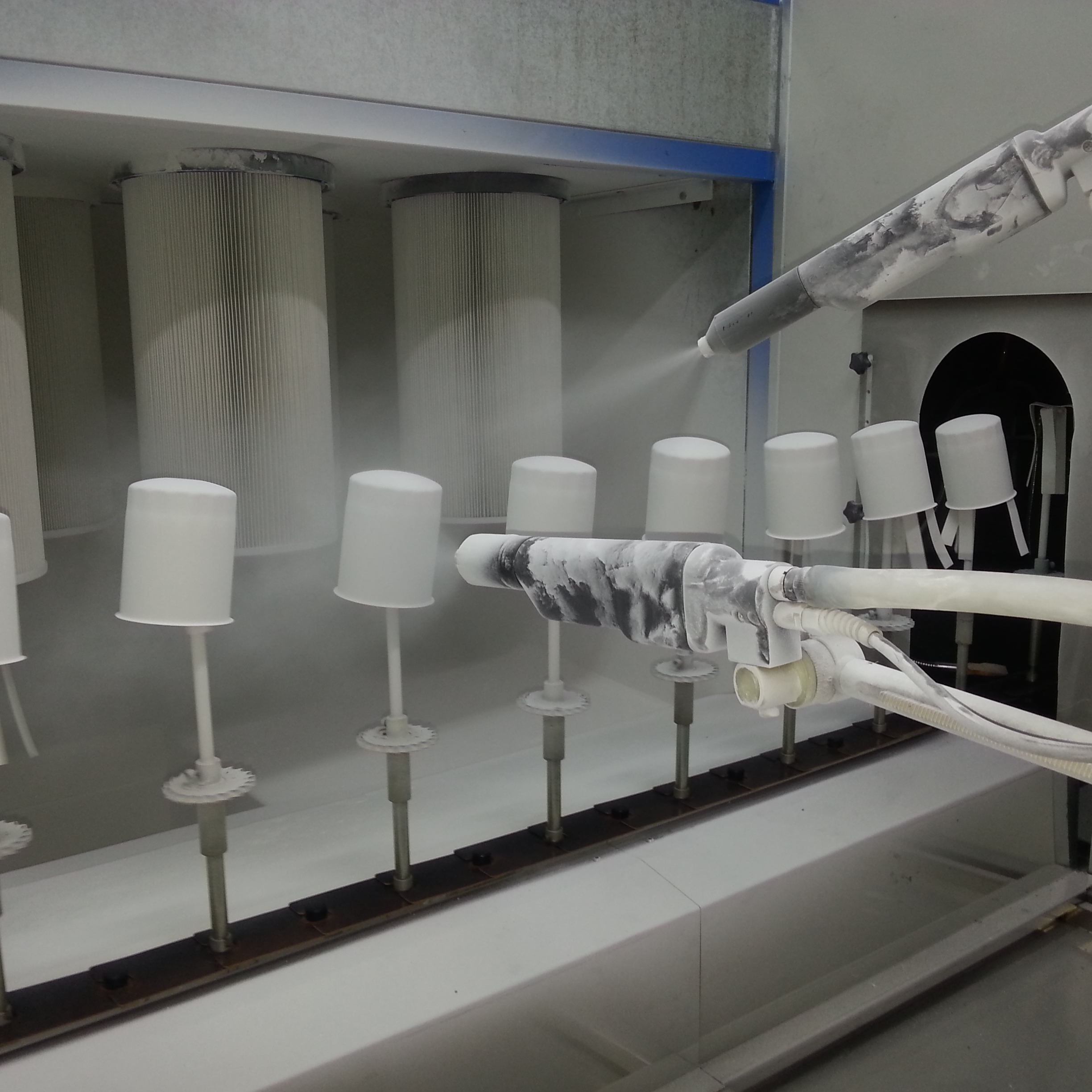

✅ Multi-Angle Spraying – Covers complex shapes & hard-to-reach areas.

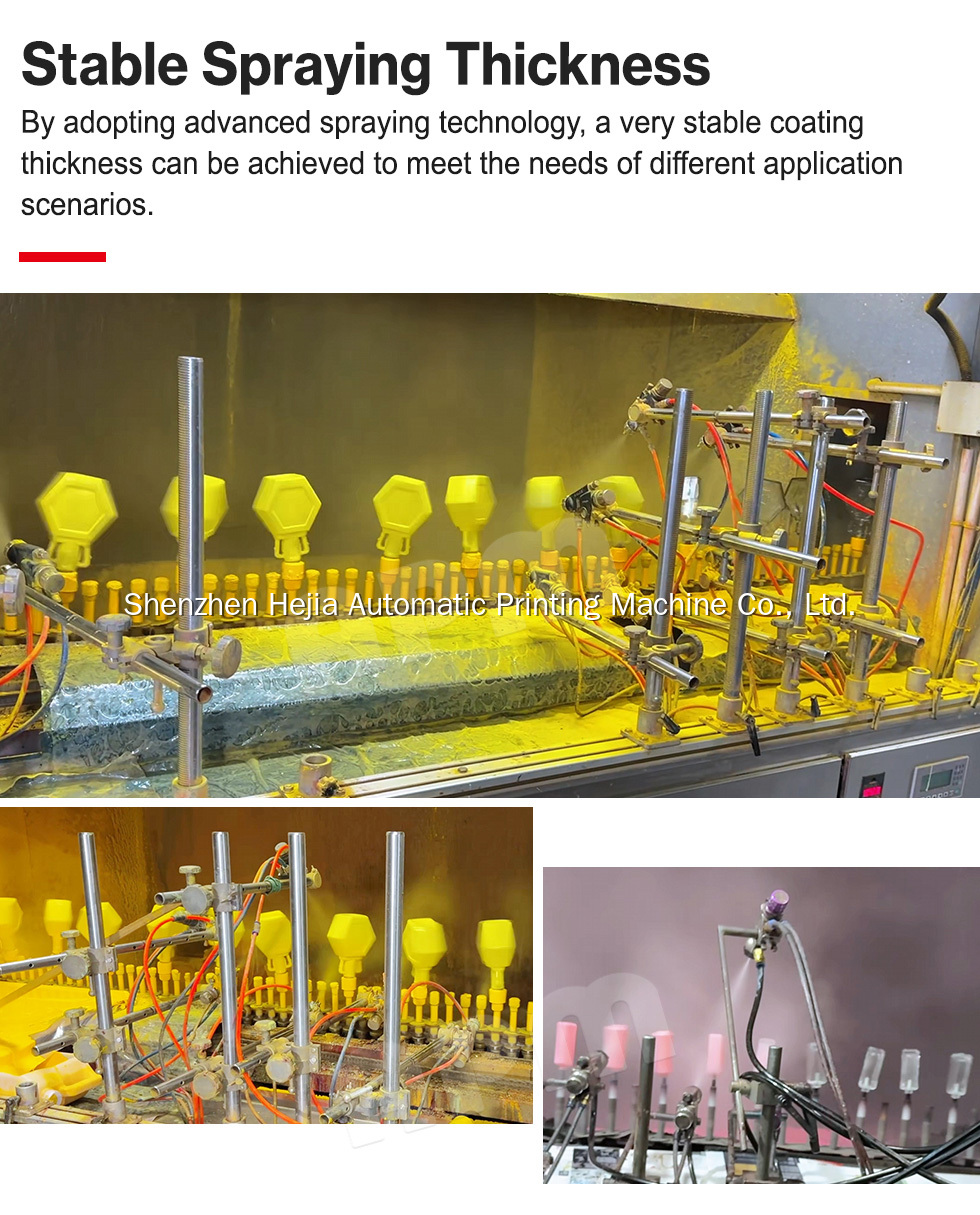

✅ Consistent Coating Quality – Ensures smooth, uniform, and high-adhesion finishes.

✅ Intelligent Control – PLC + CNC system with touch-screen operation.

2. High Efficiency & Cost Savings

✅ Automated Powder Coating & Wet Spray Coating – Suitable for various materials.

✅ 90%-95% Material Utilization – Reduces overspray & saves coating materials.

✅ Fast Cycle Time – Improves production output & reduces labor costs.

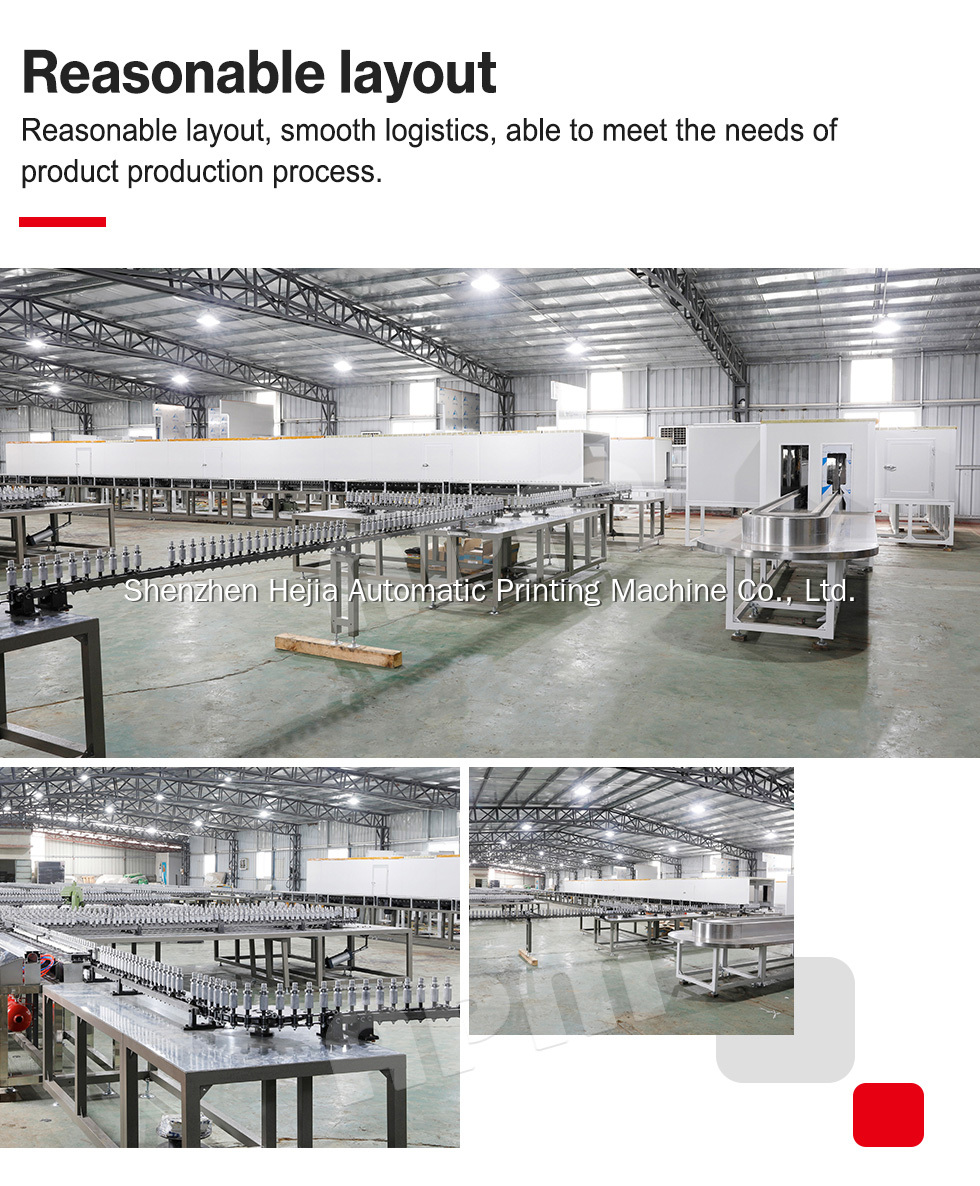

3. Modular & Customizable Design

✅ Custom Workpiece Sizes – Adapts to different metal & plastic components.

✅ Plug-and-Play Installation – Easy maintenance & quick component replacement.

✅ Environmental Friendly – Low VOC emissions, eco-friendly powder coating technology.

Revolution Speed: 0-10 RPM

Rotation Speed: 50 RPM

Max Workpiece Size: Customizable

Spraying Gun Control: YANTEN Gun System – Adjustable atomization & oil mass spraying

Reciprocating Speed: 0-2.5m/sec (Servo Motor Drive)

Control System: NC Program + PLC Central Control Unit

This UV painting line is widely used in:

✅ Metal Parts – Automotive components, appliances, machine frames.

✅ Plastic Parts – Electronic casings, plastic panels, decorative parts.

✅ Household & Industrial Products – Furniture, aluminum profiles, kitchenware.

1. Fully Automated – Reduces labor costs & increases efficiency.

2. High-Quality Finishing – Superior adhesion, durability & gloss.

3. Versatile Applications – Works with powder coating, wet painting, and UV curing.

4. Eco-Friendly & Cost-Effective – Reduces material waste & VOC emissions.

✅ On-Site Maintenance & Active Customer Engagement – Strengthening relationships and ensuring long-term customer satisfaction.

✅ Boosting Employee Productivity – Encouraging work enthusiasm and minimizing staff turnover.

✅ Understanding Customer Needs – Helping clients optimize existing production lines for cost efficiency.

🔹 Installation & Equipment Commissioning – Ensuring smooth setup & functionality.

🔹 Free Technical Training – Covering operation, maintenance, and spraying techniques.

🔹 Spare Parts Supply & Process Optimization – Reducing costs & improving efficiency.

🔹 Preventive Maintenance & Technical Advice – Minimizing downtime and preventing equipment failures.

1. What types of materials can this coating line handle?

✅ Metal Parts – Automotive components, machinery, appliances, aluminum profiles.

✅ Plastic Parts – Electronic casings, plastic caps, panels, and decorative items.

2. What coating processes does this system support?

✅ Wet Spray Coating – For smooth, uniform finishes on plastic and metal.

✅ Powder Coating – Durable, eco-friendly, and corrosion-resistant coatings.

✅ UV Curing Coating – Fast-drying for high-gloss and scratch-resistant surfaces.

3. What is the efficiency of the robotic spraying system?

✅ 90%-95% Material Utilization – Reduces overspray and coating waste.

✅ Automated Multi-Angle Spraying – Ensures full coverage and uniform coating.

✅ Fast Processing Speed – Reciprocating speed up to 2.5m/sec.

4. How is the system controlled?

✅ PLC + CNC Touch Screen Control – Easy setup and parameter adjustments.

✅ Custom Programming Support – Adapts to different workpieces and production needs.

✅ Offline Programming – Reduces on-site commissioning time.

5. Can the system be customized for specific production needs?

✅ Yes! We offer customizable solutions based on your workpiece size, coating type, and production capacity.

6. How does this system improve cost efficiency?

✅ Automated operation reduces labor costs.

✅ High material utilization saves coating materials.

✅ Eco-friendly design minimizes VOC emissions.

7. What industries use this coating line?

✅ Automotive Manufacturing – Bumpers, interior trims, alloy wheels.

✅ Electronics & Appliances – Mobile casings, laptops, household appliances.

✅ Industrial & Consumer Goods – Furniture, pipes, lighting fixtures.

8. What are the installation and maintenance requirements?

✅ Modular Plug-and-Play Design – Quick installation & minimal downtime.

✅ Easy Maintenance – Components are designed for fast replacement & servicing.

9. What are the power and space requirements?

✅ Customizable according to production capacity.

✅ Compact layout options available for space-saving installations.

10. How can I get a quote or more details?

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

slaes@apmprinter

+8618100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886