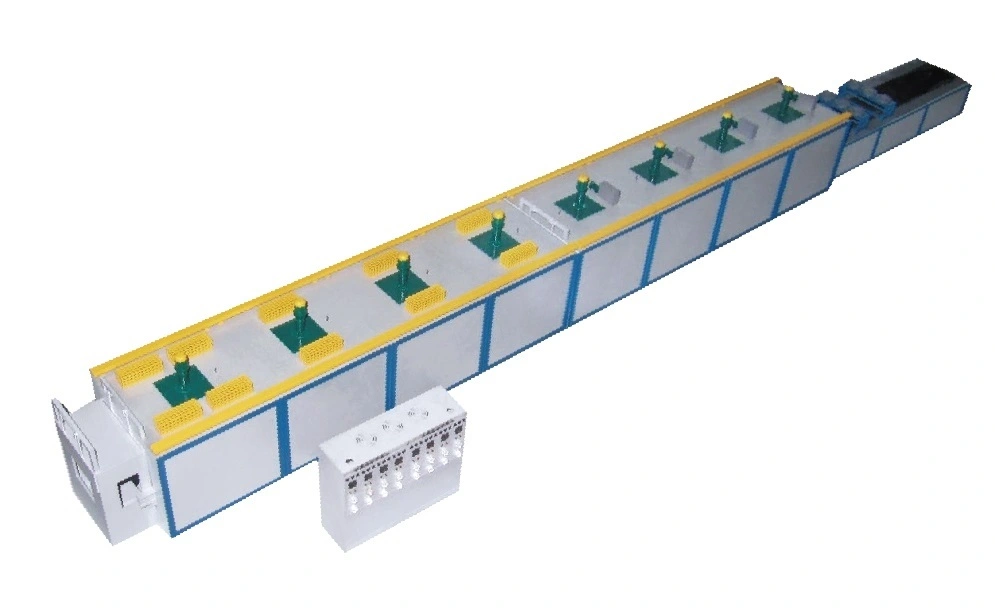

APM PRINT- APM- RT galaas kuleyliyaha sare heerkulka sare ee tunnel qalajinta IR

ELECTRIC HEATING GLASS ANNEALING FURNACE/LEHR APM-RT

Astaamaha:

1. Foornada oo dhan oo ay samaysay birta aan fiicnayn, oo loo qaybiyay qaybo kala duwan.

2. Nooca wareegga hawada kulul, kululaynta degdega ah, heerkulka gudaha waa labbis, buuq la'aan, wasakhaysan.

3. Suunka mesh waa wareegga gudaha, wuxuu dib u warshadayn karaa kulaylka qashinka ee aagga qaboojinta si uu horay u sii kululeeyo suunka mesh, u badbaadiyo tamarta, xakamaynta inta jeer.

4. Xakamaynta otomaatiga ah, xakamaynta qayb-hoosaadka, xakamaynta heerkulka tooska ah, saxnaanta waa ± 1 ℃.

5. Saamaynta daahfurka wanaagsan, tayada alaabta wax-soo-saarka ayaa wanaagsan iyo dhumucdiisu waa weyn tahay, isticmaalka tamarta yar.

Xogta farsamada:

NO | NAME | Tilmaamid | ||||||

| UNIT | APM-RT1200 | APM-RT2100 | APM-RT2400 | APM-RT3300 | APM-RT3600 | APM-RT4500 | ||

| 1 | Ballaca suunka mesh | mm | 1200 | 2100 | 2400 | 3300 | 3600 | 4500 |

| 2 | Dhererka suunka mesh | mm | 980 | |||||

| 3 | Xawaaraha suunka mesh | mm/min | 10-500 | |||||

| 4 | Heerkulka ugu badan | ℃ | 620 | |||||

| 5 | Farqiga heerkulka qaybta | ℃ | ±2 | |||||

| 6 | Dhererka qolka gubashada | mm | 350/400 | |||||

| 7 | suunka mesh culeyska ugu badan | Kg/m² | 90 | |||||

| 8 | Dhumucda haanta gudaha | mm | 3 | |||||

| 9 | Awoodda mishiinka wax-yareeya | kw | 1.1-3 | |||||

| 10 | Awoodda marawaxada wareegga | kw | 1.1-3 | |||||

| 11 | Awoodda marawaxada dib u warshadaynta kulaylka qashinka | kw | 0.75-1.5 | |||||

| 12 | Awood kuleylinta korantada | kw | 240 | 336 | 420 | |||

| 13 | Qalabka silig foornada korontada ku shaqeeya | Cr20Ni80 | ||||||

| 14 | Habka kululaynta | Kuleylinta korontada | ||||||

| 15 | Habka xakamaynta heerkulka | Xakamaynta tooska ah ee madax-banaan | ||||||

| 16 | Dhererka foornada | mm | 25000-28000 | |||||

| 17 | Ku dhig mashiinka dhalada sameeya (tixraac) | Qaybta SG2 | Qaybta BLZ10 | Qaybta SG8 | Qaybta DG10 | DG12Qof | Qaybaha DS.G.12 | |

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fakis: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Iimayl: sales@apmprinter.com

What sapp: 0086-181 0027 6886