Automatic Lipstick Tube Assembly Machine

The Automatic Lipstick Tube Assembly Machine offers high-speed, efficient assembly of 60-80 tubes per minute. Featuring an automatic loading/unloading system, customizable feeding, and defect detection, it ensures precise, reliable production. Ideal for the cosmetics industry, it’s durable, CE-certified, and comes with a one-year warranty, enhancing both efficiency and cost savings.

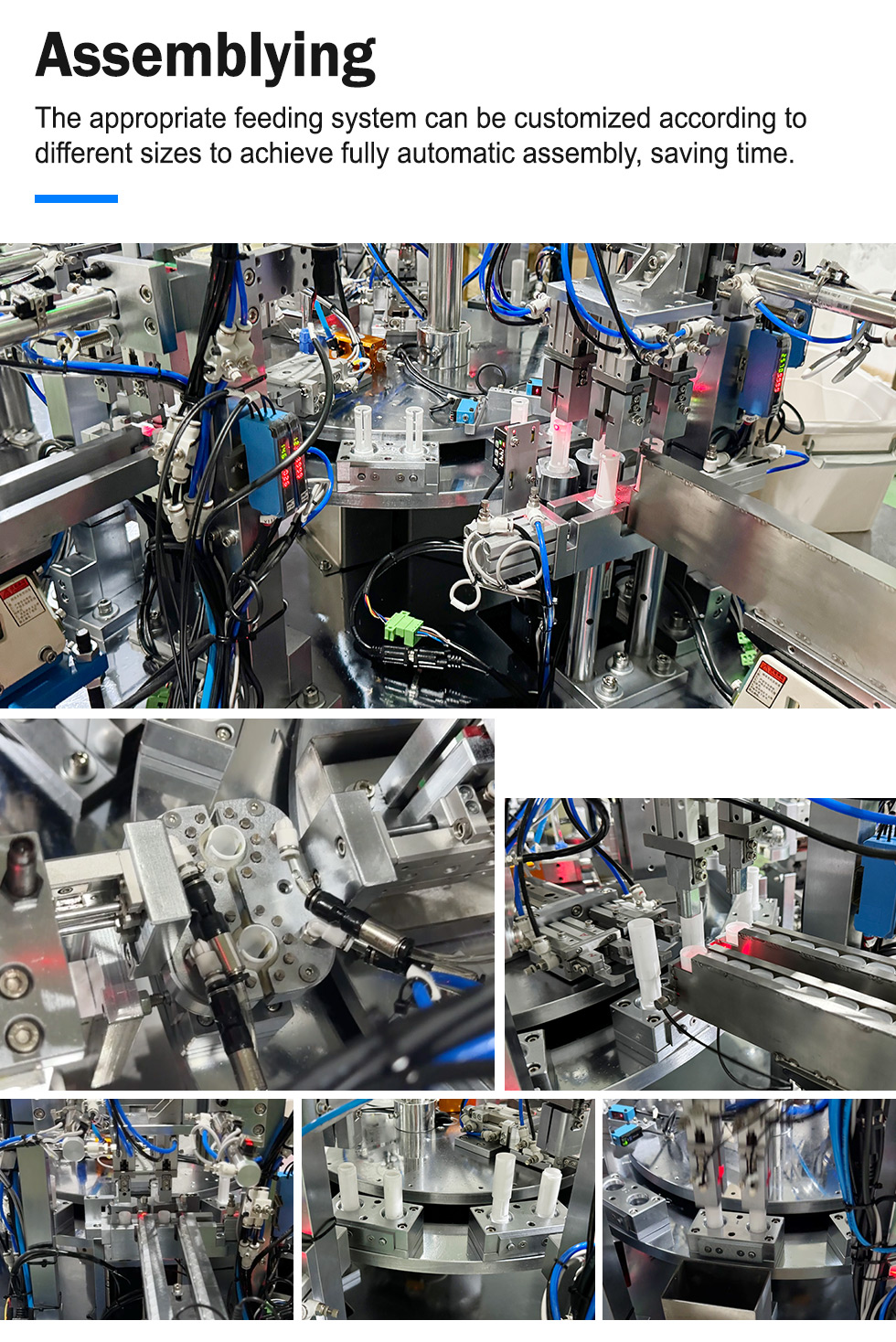

The Automatic Lipstick Tube Assembly Machine is a cutting-edge solution designed to streamline the assembly process of lipstick tubes in the cosmetics industry. This high-performance machine automates key operations such as feeding, positioning, assembly, and quality inspection, ensuring precise and efficient production. Weighing 4500 kg and with compact dimensions of 2700X1500X2300 cm, this machine is ideal for high-volume production lines. The system is equipped with an advanced vibrating feeding mechanism, automatic loading/unloading systems, and a defect detection system, all controlled by a highly reliable PLC system. With a 1-year warranty and CE certification, this machine guarantees long-lasting performance and safety.

High-Speed Assembly

The machine boasts a high production rate, capable of assembling 60-80 lipstick tubes per minute, dramatically improving overall productivity. Its automated process eliminates manual labor, increasing speed without compromising on precision.

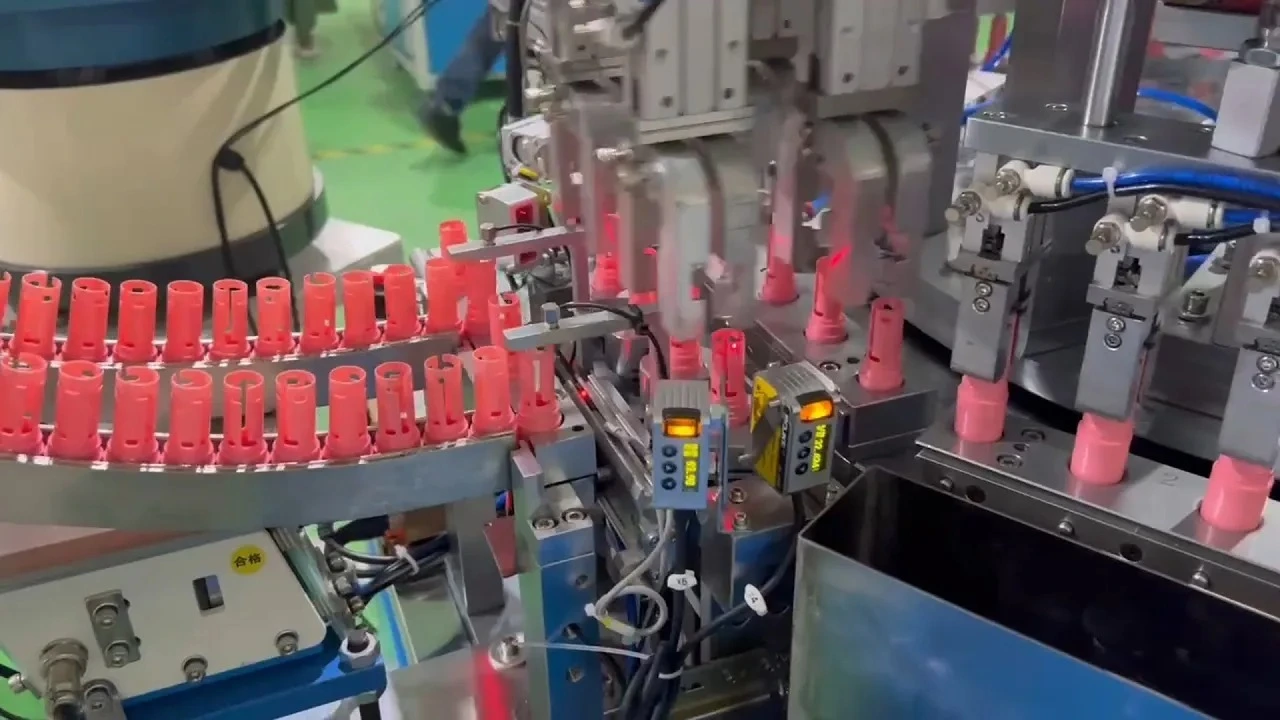

Customizable Vibrating Feeding System

The innovative vibrating feeding system is specifically designed for lipstick tubes and can be adjusted for different tube sizes. This feature ensures smooth, continuous, and efficient feeding, reducing downtime and improving throughput.

Precision and Accuracy

The Automatic Lipstick Tube Assembly Machine is equipped with a PLC control system that ensures consistent accuracy throughout the assembly process. The system guarantees high precision, with minimal errors in tube positioning, significantly reducing the defect rate.

Automatic Loading and Unloading

The integrated automatic loading and unloading systems streamline the workflow, eliminating the need for manual intervention in the tube handling process. This helps save valuable time and reduces human error.

Defective Product Detection System

Equipped with an advanced defective product detection system, the machine can automatically identify and remove defective units from the production line, ensuring that only high-quality lipstick tubes are packaged.

Durable and Reliable

Built with high-quality components, including PLCs, motors, and engines, the machine offers durability and longevity. The CE certification confirms that it adheres to international safety and quality standards, ensuring smooth operation in diverse industrial environments.

| Parameter | Automatic Lipstick Tube Assembly Machin |

Assembly Speed | 60-80 pcs/min |

Power | 5.5 K |

Weight | 4500 kg |

Dimensions (L x W x H) | 2700X1500X2300 cm |

Power Supply | 380V, 50H |

Warranty | 1 Year |

Bran | APM |

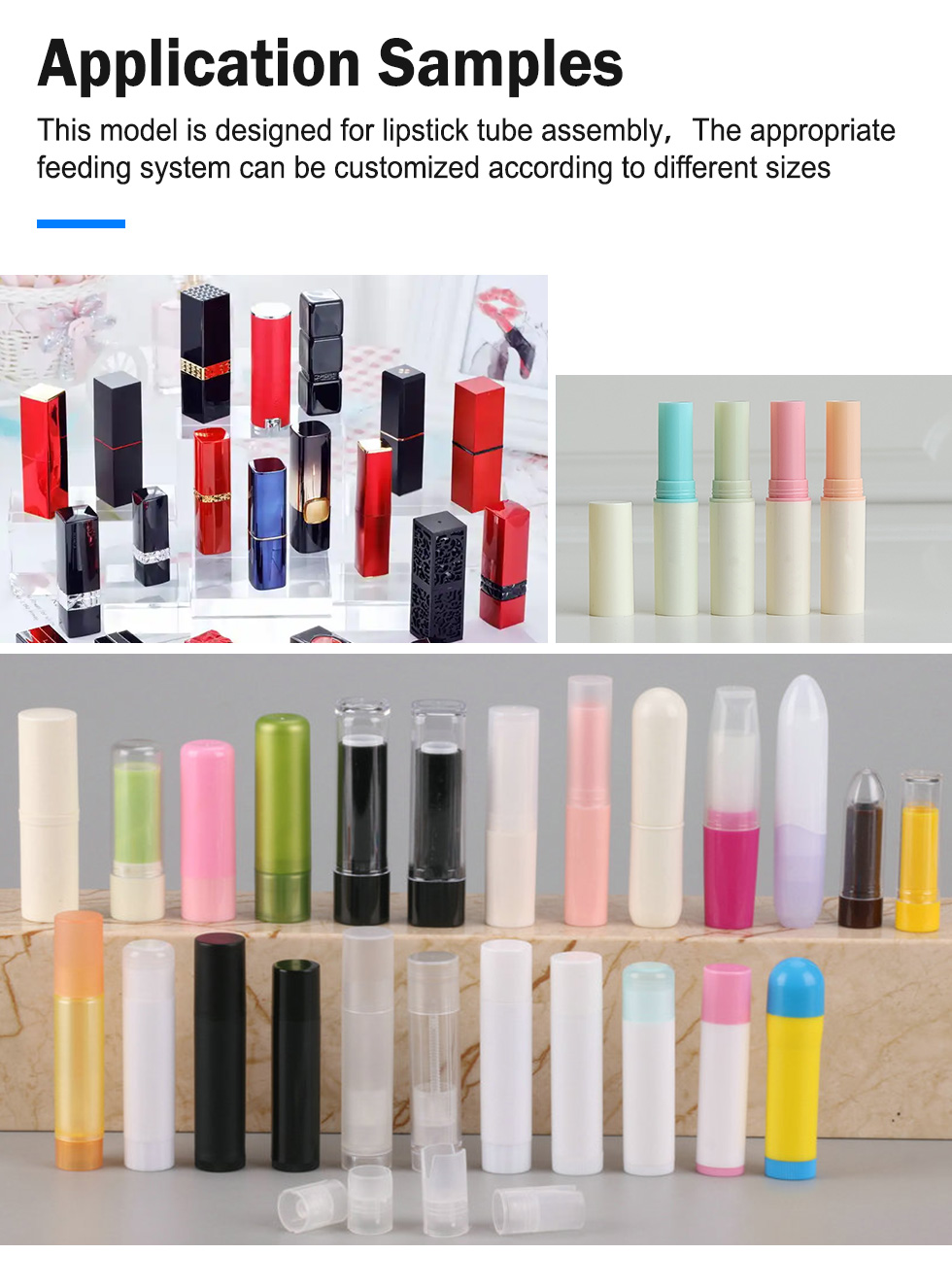

Cosmetics Industry

The Automatic Lipstick Tube Assembly Machine is primarily designed for the assembly of lipstick tubes, making it an indispensable tool in cosmetic packaging production. Its high-speed and high-accuracy features meet the demanding standards of the cosmetics market.

Medical Product Packaging

This machine can also be utilized in the assembly of packaging for disposable sterile medical products, where precision and hygiene are critical.

Consumer Goods Packaging

The machine is adaptable to various other packaging needs in the consumer goods sector, providing a flexible solution for high-volume assembly lines.

Food and Beverage Packaging

Additionally, the machine can be used for packaging food products, particularly in sectors that require careful, high-precision assembly processes.

Feeding System

Regularly inspect the vibrating feeding system for any blockages or wear. Clean the feeding tracks to ensure smooth tube delivery and adjust the feeding parameters when necessary to suit different tube sizes.

Control System

Periodic checks of the PLC control system and software updates are essential to ensure the machine operates smoothly and accurately. Ensure the control panel and wiring are kept clean and free from dust.

Motor and Engine

Inspect motors and engines for wear or overheating. Lubricate all moving parts and ensure they are in optimal condition to avoid unnecessary downtime.

Defective Product Detection System

Test and calibrate the defect detection sensors to ensure they are functioning properly. Clean the sensors and ensure there is no build-up of dust or debris that could affect their accuracy.

- Q: What is the primary function of the Automatic Lipstick Tube Assembly Machine?A: This machine is designed to automate the entire assembly process of lipstick tubes, including loading, positioning, assembly, and defect detection, greatly improving production efficiency.

- Q: What is the production capacity of the machine?A: The machine can assemble 60-80 lipstick tubes per minute, depending on the specific tube design and operational conditions.

- Q: What kind of maintenance is required for this machine?A: Regular cleaning, inspection of the feeding system, and software updates for the PLC control system are required. Periodic checks of the motor and defect detection system should also be performed.

- Q: How flexible is the machine for different tube sizes?A: The vibrating feeding system is fully adjustable for different lipstick tube sizes. Switching between sizes takes minimal time, allowing quick adaptation to production line needs.

- Q: Is the machine CE certified?A: Yes, the machine has CE certification, ensuring it meets European safety and quality standards.

- Q: Can the machine handle multiple tube styles?A: Yes, it can handle various tube shapes and sizes, making it versatile for different lipstick packaging designs.

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886