APM PRINT - Glass wine bottle cap automatic foil hot stamping machine Auto hot stamping machine

Glass wine bottle cap automatic foil hot stamping machine is made of qualified and easy-to-process raw materials. Combining all the great performance of those materials, APM PRINT is stable and durable in use.It is a perfect combination of all perfection and is bound to create benefits for customers.

An image mold or stamping die is heated to transfer metal foils or pre-dried inks to a surface during hot stamping. Hot stamping uses heated image molds or stamping dies to transfer metal foil or pre-dried ink to the surface to be marked. An engraved mold or die is heated by a hot stamping machine, which then presses marking foil onto it.

A stamping press typically has one die on top and another on the bottom. The top die is pushed down on the bottom die during use. Since the metal workpiece is sandwiched between these two dies, it will take their respective shapes. As a result, the bottom die will shape the bottom of the metal workpiece.

Because automatic stamping is reliable and reproducible, it has received significant attention. In addition to reducing manual effort, this gives marketing more time and prevents dangers that might occur when humans work in hazardous environments.

The process involves using a hot stamping machine for plastic, along with interchangeable characters made of steel, brass, or magnesium, or a solid logo die. By adding a hot stamping foil, a colored mark is created. The machine heats up the type or die and presses it against the foil, transferring the ink onto the surface of the marked part. Once lifted away, the machine completes the marking cycle and leaves behind a permanent mark on the part.

Hot stamping offers numerous advantages. It is an adaptable process that can be used on a variety of materials such as leather, plastics, rubber, and fabrics with excellent results. Hot stamping is highly preferred for monogramming and personalization purposes and has a long-standing track record. In fact, automatic hot stamping machines have been in use for over a century and are widely recognized as one of the most robust and dependable marking methods available. It is also a straightforward and reproducible process - simply load the metal die into the machine, add hot stamping foil, position the item to be marked in the fixture, and voila! Your mark is made.

There are a variety of die types and marking types available on tube hot stamping machines. Hot stamping type and dies can be made from magnesium, brass, or steel, depending on your budget and the number of items to be stamped. APM Print has extensive experience designing and recommending the best materials for your particular application.

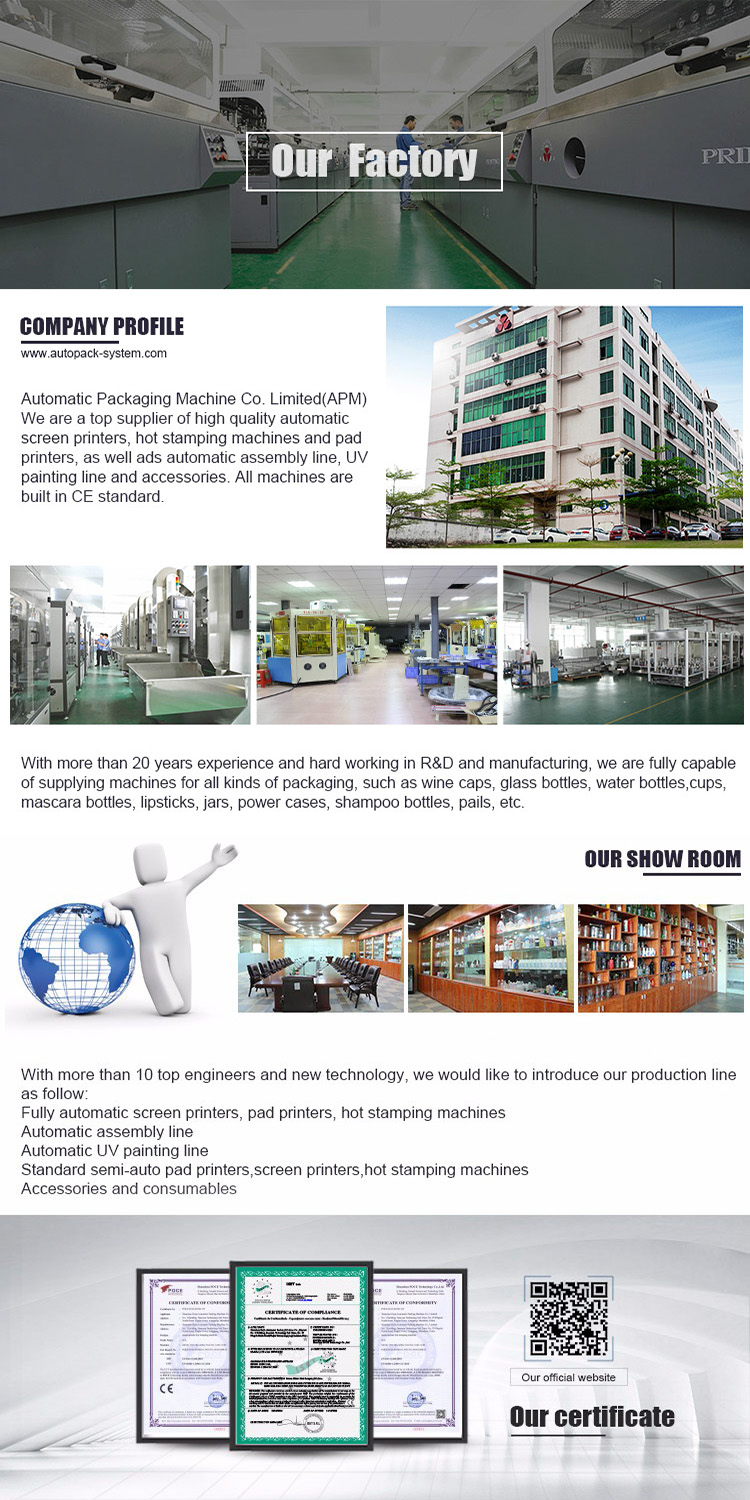

Shenzhen Hejia Automatic Printing Machine Co., Ltd. still remembered the time when we successfully developed the new product - Glass wine bottle cap automatic foil hot stamping machine. The product is absolutely new and has something different in it. In today's era,Glass wine bottle cap automatic foil hot stamping machine has proved its value in the field(s) of Screen Printers. The launch of a product that perfectly solves the industry's pain points is that Shenzhen Hejia Automatic Printing Machine Co., Ltd. has always adhered to the goal of technological innovation, and the newly developed products perfectly solve the pain points that have been lingering in the industry for a long time. Once launched, they have been enthusiastically sought after by the market.

| Plate Type: | Screen Printer | Applicable Industries: | Manufacturing Plant, Food & Beverage Factory, Printing Shops, Advertising Company, bottle making company, packaging company |

| Condition: | New | Place of Origin: | Guangdong, China |

| Brand Name: | APM | Usage: | Cap printer |

| Automatic Grade: | Automatic | Color & Page: | single color |

| Voltage: | 380V | Dimensions(L*W*H): | 128*128*200cm |

| Weight: | 800 KG | Certification: | CE certificate |

| Warranty: | 1 Year | After-sales Service Provided: | Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support |

| Key Selling Points: | Automatic | Machinery Test Report: | Provided |

| Video outgoing-inspection: | Provided | Warranty of core components: | 1 Year |

| Core Components: | Bearing, Motor, PLC, Engine | Max. speed: | 40~55pcs/min |

| Product Dia.: | 15-50mm | Length: | 20-80mm |

| Air pressure: | 6-8bar | Power supply: | 380V, 3P. 50/60Hz |

| After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service | Local Service Location: | United States, Spain |

| Showroom Location: | United States, Spain | Marketing Type: | Hot Product 2019 |

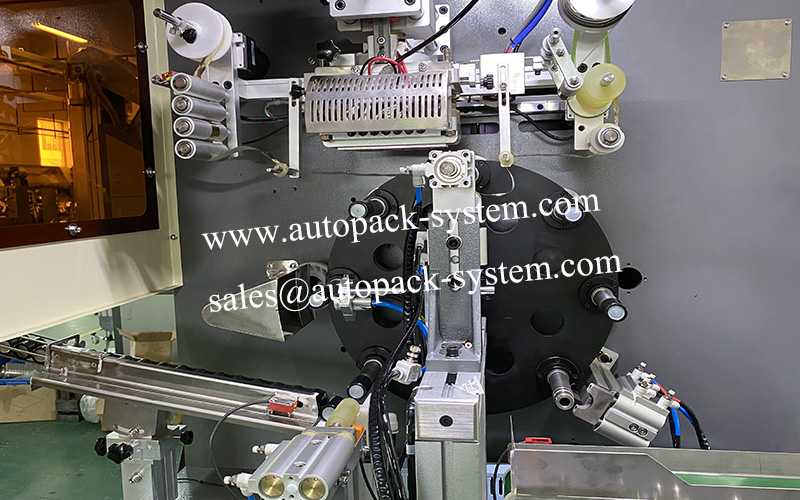

H200M automatic hot stamping machine

Application :

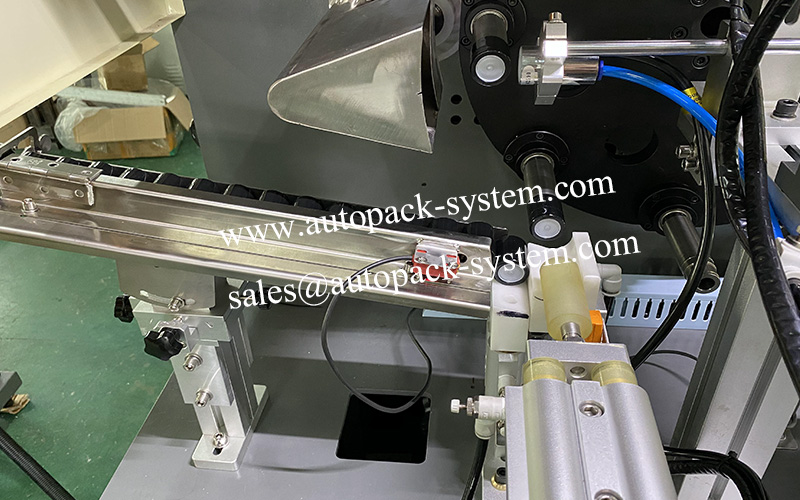

The machine is designed special for stamping on cylindrical caps.

General Description:

1. Fully automatic loading system with elevator and feeder.

2. Anti-static dust cleaning before stamping

3. Stamping with cliché

4. High accuracy indexer with 8 stations

5. Servo driven stamping head left/right.

6. PLC control and touch screen display

7. Auto unloading with counter

Tech-data

Max Speed | 40~55pcs/min |

Product Dia. | 15-50mm |

Length | 20-80mm |

Air pressure | 6-8bar |

Power supply | 380V, 3P. 50/60Hz |

Samples:

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886