Automatic Screen Printing and Hot Stamping Machine for Bottle

The Automatic Servo Screen Printing and Hot Stamping Machine integrates printing, stamping, flame treatment, dust cleaning, and UV drying. Servo-driven for high precision, it reaches 2000 pcs/hour, supporting multi-color printing and cap stamping.

The Automatic Servo Screen Printing and Hot Stamping Machine is a fully automatic device designed for bottle decorating, integrating screen printing, hot stamping, flame treatment, dust cleaning, and UV drying. It is suitable for high-precision decorating of cylindrical and irregular bottles in the cosmetics, food, and pharmaceutical industries.

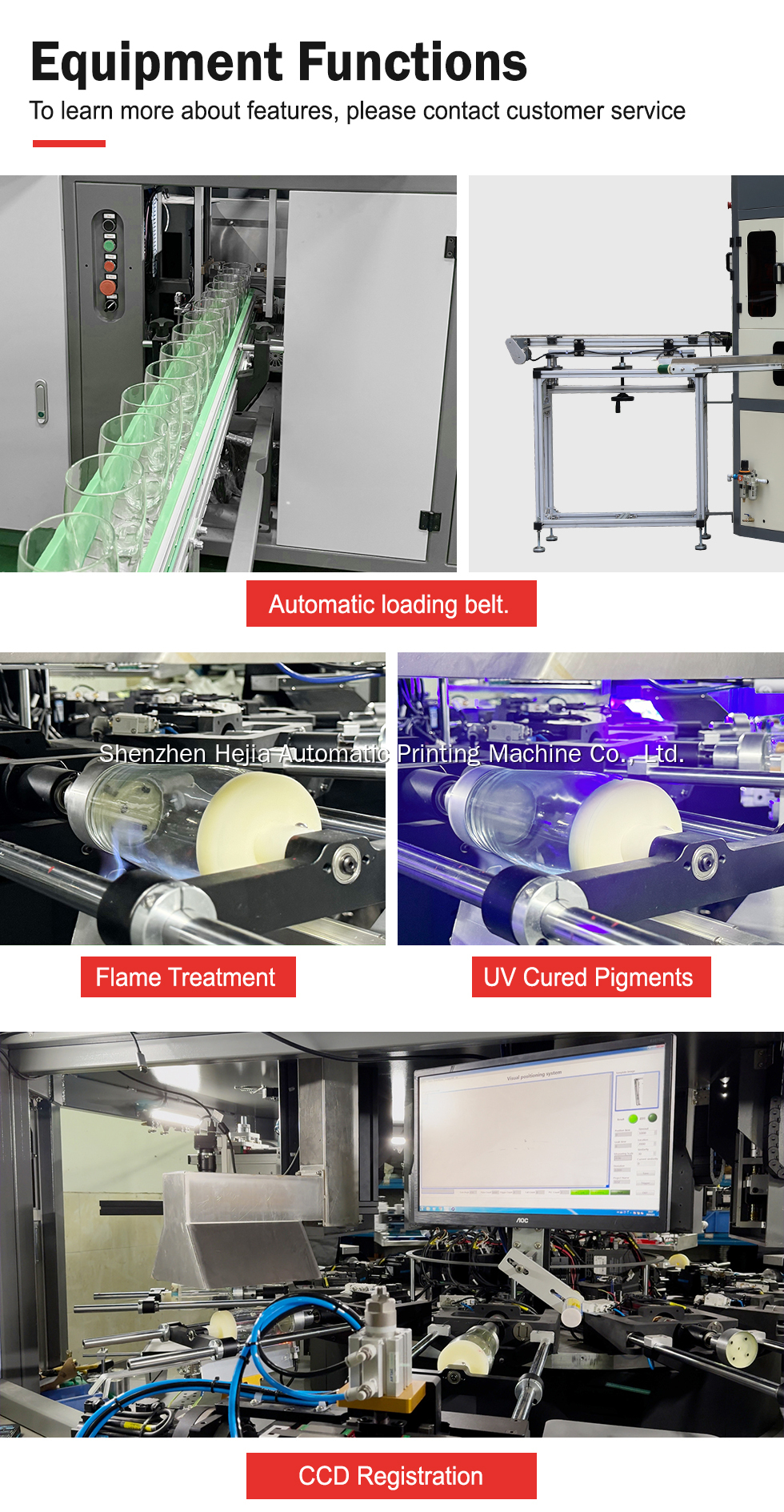

1. Fully Automatic Loading System

The Automatic Servo Screen Printing and Hot Stamping Machine features a fully automatic loading system for stable bottle handling.

2. Auto Flame Treatment & Dust Cleaning

The Automatic Servo Screen Printing and Hot Stamping Machine includes flame treatment to enhance ink adhesion and dust cleaning for a flawless surface.

3. Servo-Driven High Precision

The Automatic Servo Screen Printing and Hot Stamping Machine uses servo motors for mesh frames and jigs, ensuring alignment accuracy ≤±0.1mm.

Servo-driven jigs (gearless design) enable quick mould change and precise rotation.

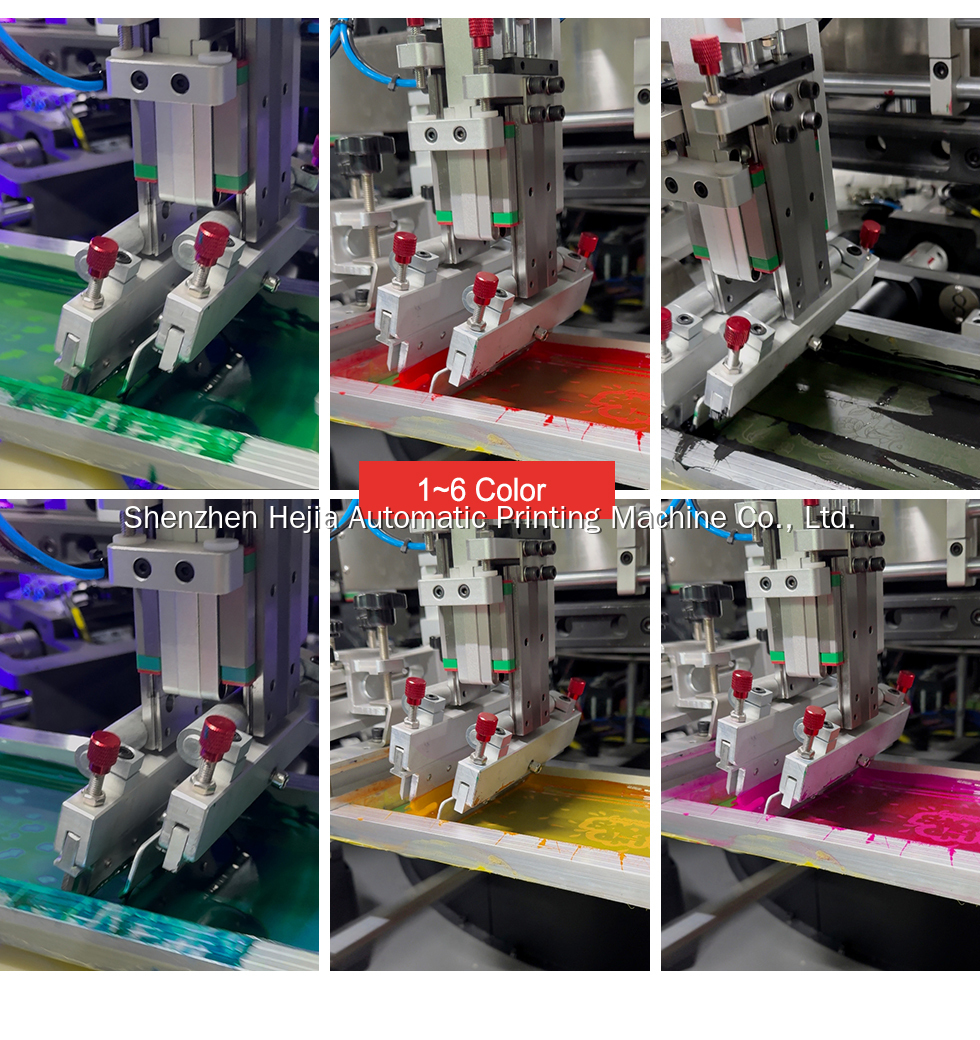

4. Multi-Color Printing & Cap Stamping

The Automatic Servo Screen Printing and Hot Stamping Machine supports multi-colour printing and cap stamping in one process.

5. Vision Alignment (Optional)

The Automatic Servo Screen Printing and Hot Stamping Machine offers an optional CCD vision system for precise double-colour printing on cylindrical products without registration points.

6. Quick Changeover & Intelligent Control

The Automatic Servo Screen Printing and Hot Stamping Machine allows product changeover within 15 minutes, with a one-touch parameter setting via touchscreen.

7. Auto UV/LED Drying

The Automatic Servo Screen Printing and Hot Stamping Machine features UV or LED drying for instant curing after each colour printing.

8. Fully Automatic Unloading

The Automatic Servo Screen Printing and Hot Stamping Machine includes a fully automatic unloading system for stable product placement.

9. CE-Certified Safety Design

The Automatic Servo Screen Printing and Hot Stamping Machine meets CE standards, with emergency stop, protective covers, and self-diagnosis features.

Parameter/Item | SS106 |

power | 380V, 3P 50/60Hz |

Air consumption | 6-8bar |

Max Printing Speed | 40-60pcs/min (with stamp/lacker speed is slower, only screen print higher speed.) |

Max. printing Dia. | 40mm |

Max. printing circumstance | 120mm |

Max. product height | 70mm |

1. Cosmetic Bottles: Hot stamping on lipstick tubes, gradient patterns on serum bottles.

2. Food & Beverage: Label printing on glass bottles, and decorative stamping on cans.

3. Medical Bottles: Scale printing, anti-counterfeit labels.

4. Daily Chemicals: Hot stamping on shampoo bottles, printing on disinfectant containers.

Customization: Tailored solutions for special bottle shapes and processes.

Global Delivery: Ships within 45 working days, with on-site installation and training.

Warranty: 1-year full machine warranty, lifetime technical support.

1. What is the Automatic Servo Screen Printing and Hot Stamping Machine?

✅ The Automatic Servo Screen Printing and Hot Stamping Machine is a fully automatic device integrating screen printing, hot stamping, flame treatment, dust cleaning, and UV drying for bottle decorating.

2. Can the Automatic Servo Screen Printing and Hot Stamping Machine perform printing and stamping simultaneously?

✅ Yes, it completes multi-colour printing and cap stamping in one process.

3. Does the Automatic Servo Screen Printing and Hot Stamping Machine support various bottle shapes?

✅ Yes, it adapts to cylindrical, oval, and square bottles with quick mould change.

4. How is stamping precision ensured?

✅ Servo systems guarantee alignment accuracy ≤±0.1mm.

5. What is the production speed?

✅ Up to 2000 pcs/hour for printing, 1800 pcs/hour for stamping.

6. Does the Automatic Servo Screen Printing and Hot Stamping Machine support vision alignment?

✅ Optional CCD vision system ensures precise double-colour printing for cylindrical products.

7. Is the Automatic Servo Screen Printing and Hot Stamping Machine CE-certified?

✅ Yes, it meets international safety and quality standards.

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886