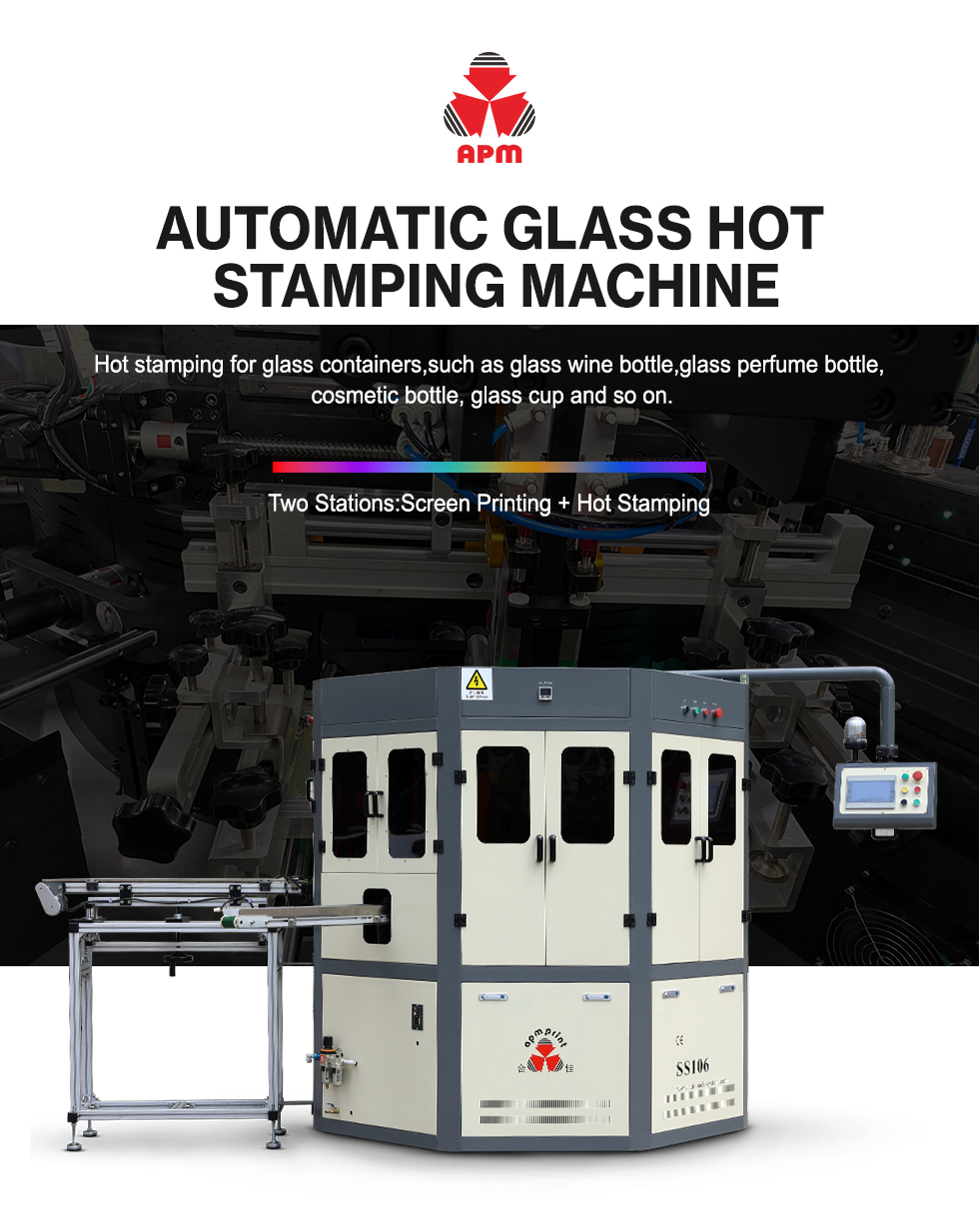

Glass bottle hot stamping machine

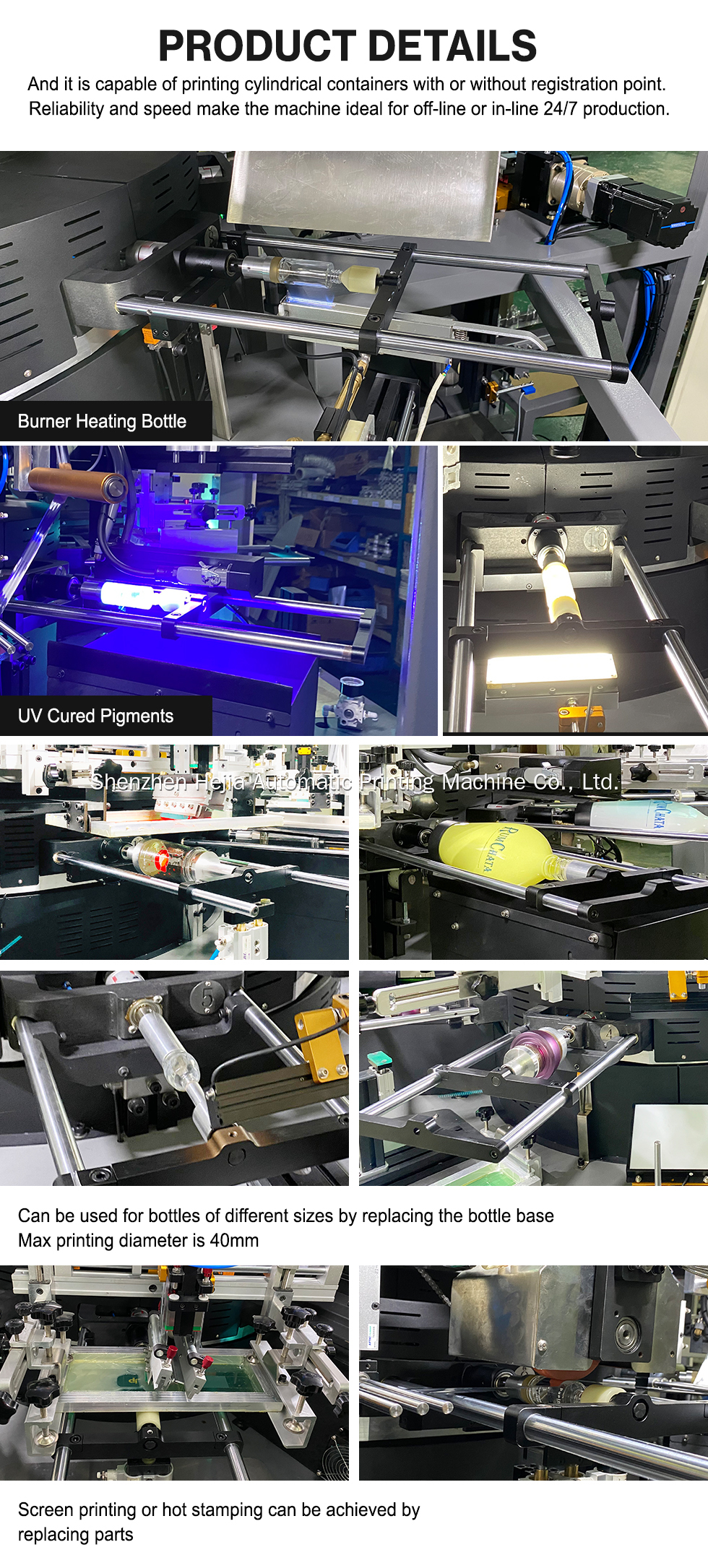

The Glass Bottle Hot Stamping Machine offers dual-station screen printing and hot stamping for glass containers (max print diameter 40mm), supporting containers with/without registration points and 24/7 high-efficiency production.

The Glass Bottle Hot Stamping Machine is a dual-station device designed for glass containers (wine/perfume/cosmetic bottles, cups), combining screen printing and hot stamping. It supports high-speed multi-color decoration, handles containers with/without registration points (max printing diameter 40mm), and is ideal for 24/7 production in cosmetics, luxury packaging, and beverage industries.

1. Dual-Station Efficiency

✅Perform screen printing and hot stamping in one machine.

✅Compatible with UV inks for fast curing and high adhesion.

2. Multi-Size Adaptability

✅Adjustable bottle bases for different sizes (max print diameter 40mm).

3. High Reliability

✅Designed for continuous 24/7 operation with minimal downtime.

4. Quick Changeover

✅Swap screen plates or stamping modules in 15 minutes.

Parameter | Specification |

Applicable Containers | Glass/plastic bottles, jars, caps |

Max Printing Diameter | 40mm |

Processes | Screen Printing and Hot Stamping |

Registration Points | Supported (optional) |

Ink Compatibility | UV Inks |

1. Luxury Wine Bottles: Label printing and logo stamping.

2. Perfume Bottles: Gradient prints and embossed foil.

3. Cosmetic Packaging: Security codes and metallic cap stamping.

4. Giftware: Full-wrap designs and festive foil accents.

Delivery: 45 working days after deposit.

Payment: 30% deposit, 70% balance before shipment.

Warranty: 1-year full machine warranty.

1. Can the Glass bottle hot stamping machine perform screen printing and hot stamping simultaneously?

✅ Yes, dual-station design enables simultaneous or sequential processes.

2. Does the Glass bottle hot stamping machine support containers without registration points?

✅ Yes, advanced alignment technology eliminates the need for registration marks.

3. What is the max bottle diameter supported by the Glass bottle hot stamping machine?

✅ Max printing diameter is 40mm (adjustable for bottle size).

4. How long does bottle changeover take the Glass bottle hot stamping machine?

✅ 15 minutes to swap bottle bases and fixtures.

5. Is the Glass bottle hot stamping machine compatible with plastic bottles?

✅ Yes, works with both glass and plastic containers.

6. What is the Glass bottle hot stamping machine production speed?

✅ Industry-leading speed, adjustable based on process complexity.

7. Does the Glass bottle hot stamping machine UV ink require separate curing?

✅ No, integrated UV curing module included.

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886