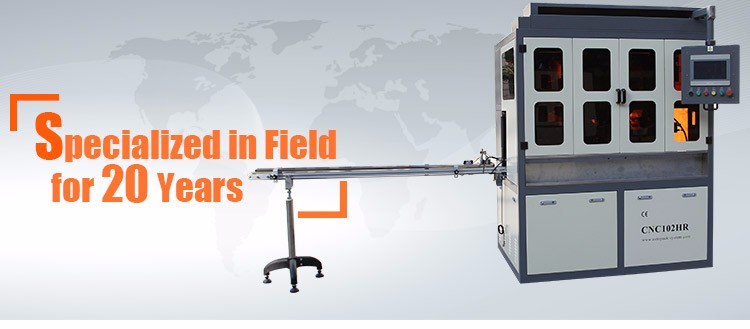

APM PRINT - CNC10 Led Uv Cuiring System Glass Mugs Automatic Screen Printer Auto hot stamping machine

In order to better adapt to the diversified needs of customers,Shenzhen Hejia Automatic Printing Machine Co., Ltd. has been working hard to develop products. CNC10 Led Uv Cuiring System Glass Mugs Automatic Screen Printer with reasonable price, excellent performance and excellent quality, it has won wide recognition from customers. The research and development of CNC10 Led Uv Cuiring System Glass Mugs Automatic Screen Printer has further improved the company's market competitiveness.

| Type: | Heat Press Machine | Applicable Industries: | Manufacturing Plant, Printing Shops |

| Condition: | New | Plate Type: | Letterpress |

| Place of Origin: | Guangdong, China | Brand Name: | APM |

| Model Number: | CNC102HR | Usage: | Glass Bottle Stamping |

| Automatic Grade: | Automatic | Color & Page: | Multicolor |

| Voltage: | 380V | Dimensions(L*W*H): | 1800 x 1320 x 22000mm |

| Weight: | 1200kgs | Warranty: | 1 Year |

| After-sales Service Provided: | Online support, Video technical support, Engineers available to service machinery overseas | Certification: | CE Certificate |

| Product Name: | Led Uv Cuiring System Glass Mugs Automatic Screen Printer | Application: | Glass Bottle Stamping |

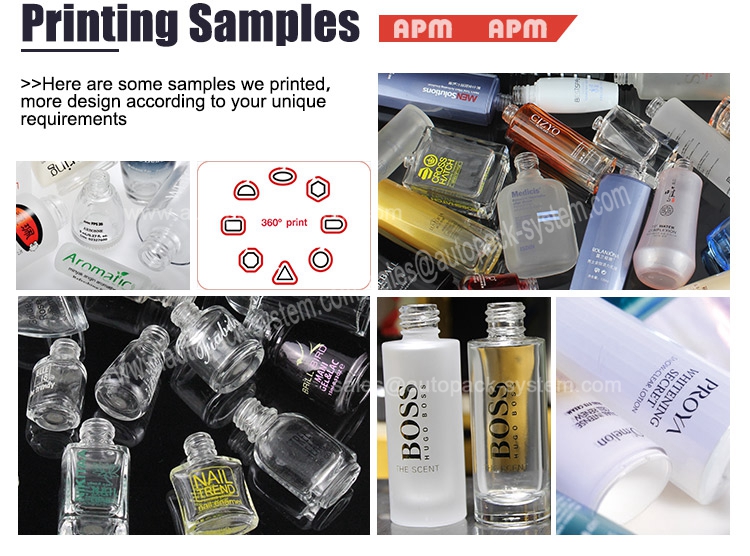

| Printing Speed: | Max. 30pcs/min, normal: 20-27pcs/min | Printing Size(Round Container): | Dia.20-90mm & Len. 30-180mm |

| Printing Size(Irregular container): | Wid. 20-100mm & Len. 30-180mm |

Tech-data

Product Name | Led Uv Cuiring System Glass Mugs Automatic Screen Printer |

Printing speed | Max. 30pcs/min, normal: 20-27pcs/min |

| Power | 380V, 3P 50/60HZ |

| Air pressure | 6-8Bar |

Round Container |

|

Printing diameter | 20-90mm |

Printing length | 30-180mm |

Square/Irregular container |

|

Printing Width | 20-100mm |

Printing Length | 30-180mm |

Application

All shapes of glass bottles.

General Description

1. Loading belt. Bottle standing on belt.

Loading belt length:2m, unloading belt length: 1.2m (outside machine length: 0.5m)

Extra : 90°after unloading belt add another belt 1.5m and a buffer (diameter: 1m)

2. Mechanical registration

3. Servo motor driven: pre-registration, product rotate, product left/right moving, product up/down moving, foil winding

4. Multi sides printing in one process.

5. Super quick and easy change over from one product to another.

6. All parameters automatic setting simply in touch screen.

7. Automatic unloading with servo robot. Bottle standing unloading.

8. Safety operation with CE.

9. Repeat print to be multi colors.

Two machines in line:

1. Two machines can combine together, transfer from screen printing to hot stamping directly, no belts between two machines but a device with wheels;

2. Two machines can separate, with two more belts between two machines, all belts in one line (direction).

3. With one page on touch screen to input password and choose if we need to separate two machines. (if we need to use extra belts).

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886