hot stamping machine manufacturers at Wholesale Prices | APM PRINT1

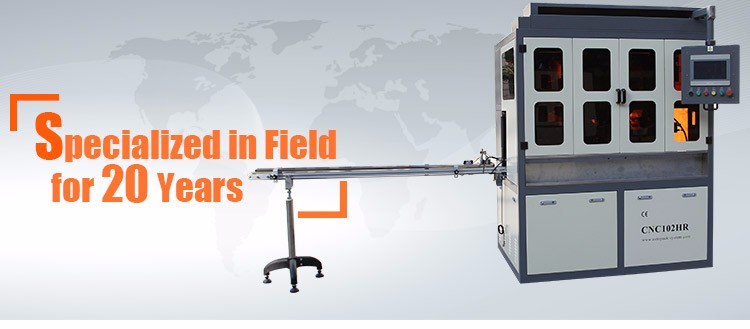

Over the years, APM PRINT has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. hot stamping machine manufacturers Today, APM PRINT ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product hot stamping machine manufacturers and our company by directly contacting us.APM PRINT is a fruit born out of diverse knowledge subjects. Its development process employs a range of technologies such as CNC, power machinery, mechanical engineering, tribology, thermodynamics, and more. So, if you're looking for a brand that leverages a multitude of innovative tech, APM PRINT may be just the solution you need.

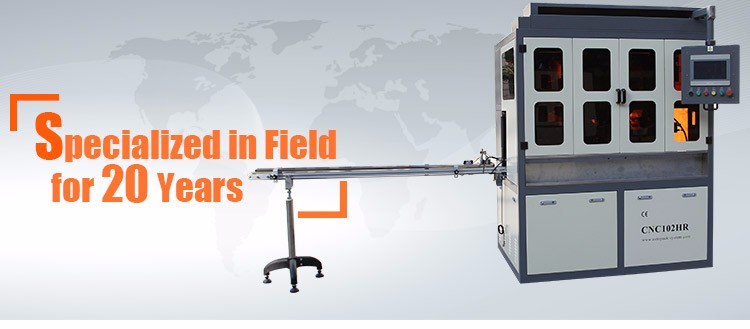

After months of furious yet meaningful development work, Shenzhen Hejia Automatic Printing Machine Co., Ltd. has made it a great success to work out Heavy Duty Hot Stamping Machine For Glass Bottle. The product is supplied with multiple features and a broad range of applications. It is designed to cater to the changing demands and requisites of customers. Our goal is to exceed the quality expectations of our customers. This commitment starts with the top-level management and extends through the entire enterprise. This can be achieved through innovation, technical excellence, and continuous improvement. In this way, Shenzhen Hejia Automatic Printing Machine Co., Ltd. firmly believe that we will satisfy the growing needs of every customer.

| Type: | Heat Press Machine | Applicable Industries: | Manufacturing Plant, Printing Shops |

| Condition: | New | Plate Type: | Letterpress |

| Place of Origin: | Guangdong, China | Brand Name: | APM |

| Model Number: | CNC102HR | Usage: | Glass Bottle Stamping |

| Automatic Grade: | Automatic | Color & Page: | Multicolor |

| Voltage: | 380V | Dimensions(L*W*H): | 1800 x 1320 x 22000mm |

| Weight: | 1200 KG | Warranty: | 1 Year |

| Key Selling Points: | Automatic | Machinery Test Report: | Provided |

| Video outgoing-inspection: | Provided | Warranty of core components: | 1 Year |

| Core Components: | Motor, PLC | After-sales Service Provided: | No overseas service provided, Online support, Video technical support |

| Product Name: | Heavy Duty Hot Stamping Machine For Glass Bottle | Application: | Glass Bottle Stamping |

| Printing Speed: | Max. 30pcs/min, normal: 20-27pcs/min | Printing Size(Round Container): | Dia.20-90mm & Len. 30-180mm |

| Printing Size(Irregular container): | Wid. 20-100mm & Len. 30-180mm | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | United States, Spain | Showroom Location: | United States, Spain |

| Marketing Type: | Ordinary Product | Certification: | CE Certificate |

Tech-data

|

Printing speed |

Max. 30pcs/min, normal: 20-27pcs/min |

| Power |

380V, 3P 50/60HZ |

| Air pressure |

6-8Bar |

|

Round Container |

|

|

Printing diameter |

20-90mm |

|

Printing length |

30-180mm |

|

Square/Irregular container |

|

|

Printing Width |

20-100mm |

|

Printing Length |

30-180mm |

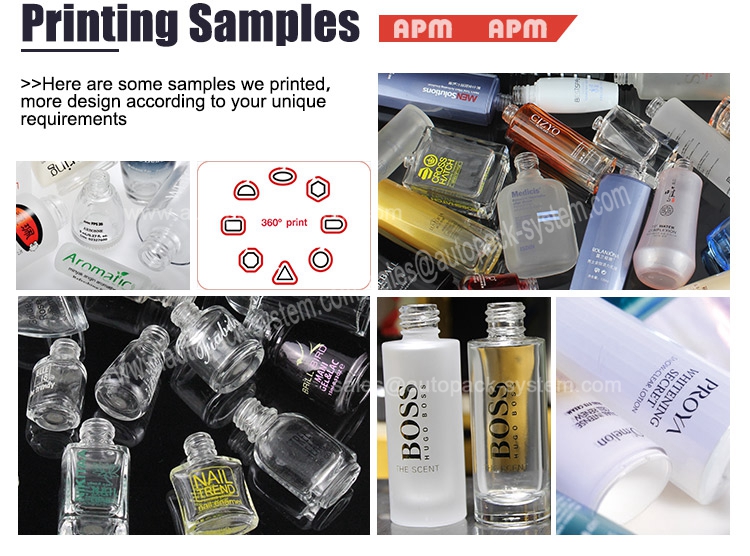

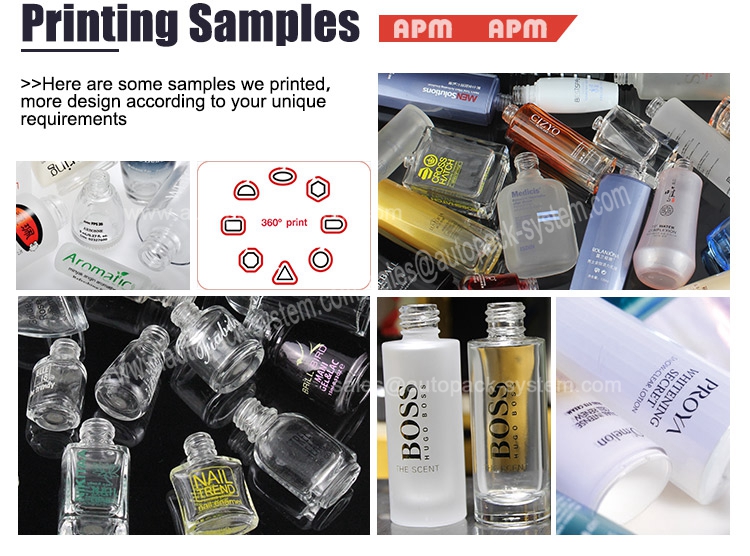

Application

All shapes of glass bottles.

General Description

1. Loading belt. Bottle standing on belt.

Loading belt length:2m, unloading belt length: 1.2m (outside machine length: 0.5m)

Extra : 90°after unloading belt add another belt 1.5m and a buffer (diameter: 1m)

2. Mechanical registration

3. Servo motor driven: pre-registration, product rotate, product left/right moving, product up/down moving, foil winding

4. Multi sides printing in one process.

5. Super quick and easy change over from one product to another.

6. All parameters automatic setting simply in touch screen.

7. Automatic unloading with servo robot. Bottle standing unloading.

8. Safety operation with CE.

9. Repeat print to be multi colors.

Two machines in line:

1. Two machines can combine together, transfer from screen printing to hot stamping directly, no belts between two machines but a device with wheels;

2. Two machines can separate, with two more belts between two machines, all belts in one line (direction).

3. With one page on touch screen to input password and choose if we need to separate two machines. (if we need to use extra belts).

Over the years, APM PRINT has been offering customers high-quality products and efficient after-sales services with the aim of bringing unlimited benefits for them. hot stamping machine manufacturers Today, APM PRINT ranks the top as a professional and experienced supplier in the industry. We can design, develop, manufacture, and sell different series of products on our own combining the efforts and wisdom of all our staff. Also, we are responsible for offering a wide range of services for customers including technical support and prompt Q&A services. You may discover more about our new product hot stamping machine manufacturers and our company by directly contacting us.APM PRINT is a fruit born out of diverse knowledge subjects. Its development process employs a range of technologies such as CNC, power machinery, mechanical engineering, tribology, thermodynamics, and more. So, if you're looking for a brand that leverages a multitude of innovative tech, APM PRINT may be just the solution you need.

After months of furious yet meaningful development work, Shenzhen Hejia Automatic Printing Machine Co., Ltd. has made it a great success to work out Heavy Duty Hot Stamping Machine For Glass Bottle. The product is supplied with multiple features and a broad range of applications. It is designed to cater to the changing demands and requisites of customers. Our goal is to exceed the quality expectations of our customers. This commitment starts with the top-level management and extends through the entire enterprise. This can be achieved through innovation, technical excellence, and continuous improvement. In this way, Shenzhen Hejia Automatic Printing Machine Co., Ltd. firmly believe that we will satisfy the growing needs of every customer.

| Type: | Heat Press Machine | Applicable Industries: | Manufacturing Plant, Printing Shops |

| Condition: | New | Plate Type: | Letterpress |

| Place of Origin: | Guangdong, China | Brand Name: | APM |

| Model Number: | CNC102HR | Usage: | Glass Bottle Stamping |

| Automatic Grade: | Automatic | Color & Page: | Multicolor |

| Voltage: | 380V | Dimensions(L*W*H): | 1800 x 1320 x 22000mm |

| Weight: | 1200 KG | Warranty: | 1 Year |

| Key Selling Points: | Automatic | Machinery Test Report: | Provided |

| Video outgoing-inspection: | Provided | Warranty of core components: | 1 Year |

| Core Components: | Motor, PLC | After-sales Service Provided: | No overseas service provided, Online support, Video technical support |

| Product Name: | Heavy Duty Hot Stamping Machine For Glass Bottle | Application: | Glass Bottle Stamping |

| Printing Speed: | Max. 30pcs/min, normal: 20-27pcs/min | Printing Size(Round Container): | Dia.20-90mm & Len. 30-180mm |

| Printing Size(Irregular container): | Wid. 20-100mm & Len. 30-180mm | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | United States, Spain | Showroom Location: | United States, Spain |

| Marketing Type: | Ordinary Product | Certification: | CE Certificate |

Tech-data

|

Printing speed |

Max. 30pcs/min, normal: 20-27pcs/min |

| Power |

380V, 3P 50/60HZ |

| Air pressure |

6-8Bar |

|

Round Container |

|

|

Printing diameter |

20-90mm |

|

Printing length |

30-180mm |

|

Square/Irregular container |

|

|

Printing Width |

20-100mm |

|

Printing Length |

30-180mm |

Application

All shapes of glass bottles.

General Description

1. Loading belt. Bottle standing on belt.

Loading belt length:2m, unloading belt length: 1.2m (outside machine length: 0.5m)

Extra : 90°after unloading belt add another belt 1.5m and a buffer (diameter: 1m)

2. Mechanical registration

3. Servo motor driven: pre-registration, product rotate, product left/right moving, product up/down moving, foil winding

4. Multi sides printing in one process.

5. Super quick and easy change over from one product to another.

6. All parameters automatic setting simply in touch screen.

7. Automatic unloading with servo robot. Bottle standing unloading.

8. Safety operation with CE.

9. Repeat print to be multi colors.

Two machines in line:

1. Two machines can combine together, transfer from screen printing to hot stamping directly, no belts between two machines but a device with wheels;

2. Two machines can separate, with two more belts between two machines, all belts in one line (direction).

3. With one page on touch screen to input password and choose if we need to separate two machines. (if we need to use extra belts).

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886