Offset Printing Machine

The Plastic Tube Printer is a high-efficiency printing machine designed for precise and high-quality printing on plastic tubes made from materials like PP, PS, and PET. Equipped with advanced offset printing technology, it offers vibrant and detailed prints for various applications. The machine supports printing speeds of up to 60-100 pieces per minute, with a UV curing system that ensures durable, long-lasting results. Its energy-efficient design and automatic ink-cleaning system reduce waste, making it an ideal choice for industries such as cosmetics, food packaging, and pharmaceuticals.

The APM-G6055B Plastic Tube Printer is a state-of-the-art machine designed for high-speed and high-quality printing on plastic tubes. It supports a wide range of materials, including PP, PS, and PET, and accommodates various tube diameters and lengths. Whether for manual or automatic feeding, this machine integrates advanced printing technologies to ensure precise, efficient, and visually stunning results.

1. High-Speed Printing

Manual Feeding Model: Supports printing speeds of 60–80 pcs/min.

Automatic Feeding Model: Achieves speeds of up to 100 pcs/min.

2. Versatile Printing Specifications

Tube Diameter: 22–55 mm.

Tube Length: 30–220 mm.

Maximum Printing Width: 172 mm.

Maximum Printing Length: 190 mm.

3. Comprehensive Printing Process

The machine integrates multiple steps into a seamless process:

Manual/Automatic Tube Feeding → Corona Treatment → Printing → Varnishing → UV Curing → Tube Out.

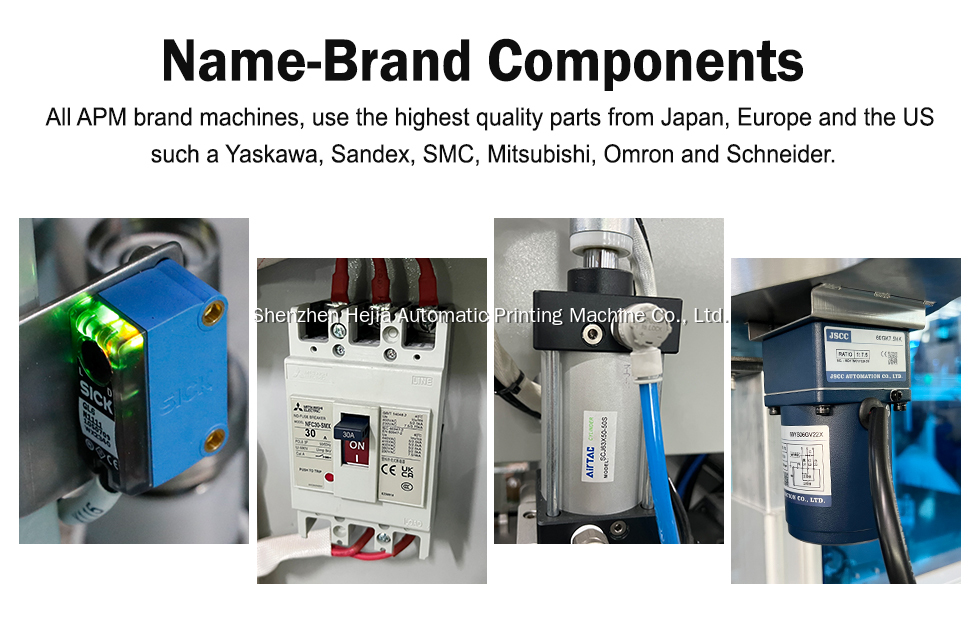

4. Modular Electrical Components

Equipped with Schneider, ABB, SIEMENS, and other reliable brands to ensure stable operation and easy maintenance.

Components like PLC Displayer, Servo Motors, and Inverters enhance operational efficiency and precision.

5. Durability and Efficiency

Features high-quality components such as Japanese timing belts and AIRTAR air cylinders, ensuring long-term reliability.

An optimized UV drying system and automatic ink cleaning significantly improve energy efficiency and reduce waste.

6. Customizable Options

Manual or automatic feeding models are available to suit production requirements.

Compatible with a wide variety of ink types for diverse printing applications.

Maximum Printing Speed | 60–100 pcs/min |

Printing Colors | 1-8 |

Tube Diameter | 22–55 mm |

Tube Length | 30–220 mm |

Maximum Printing Width | 172 mm |

Maximum Printing Length | 190 mm |

Applicable Materials | PP, PS, PET |

Essential Maintenance Tips

Regularly check and clean the UV curing system, ink pipelines, and rollers.

Ensure proper calibration of pneumatic components and servo motors for consistent performance.

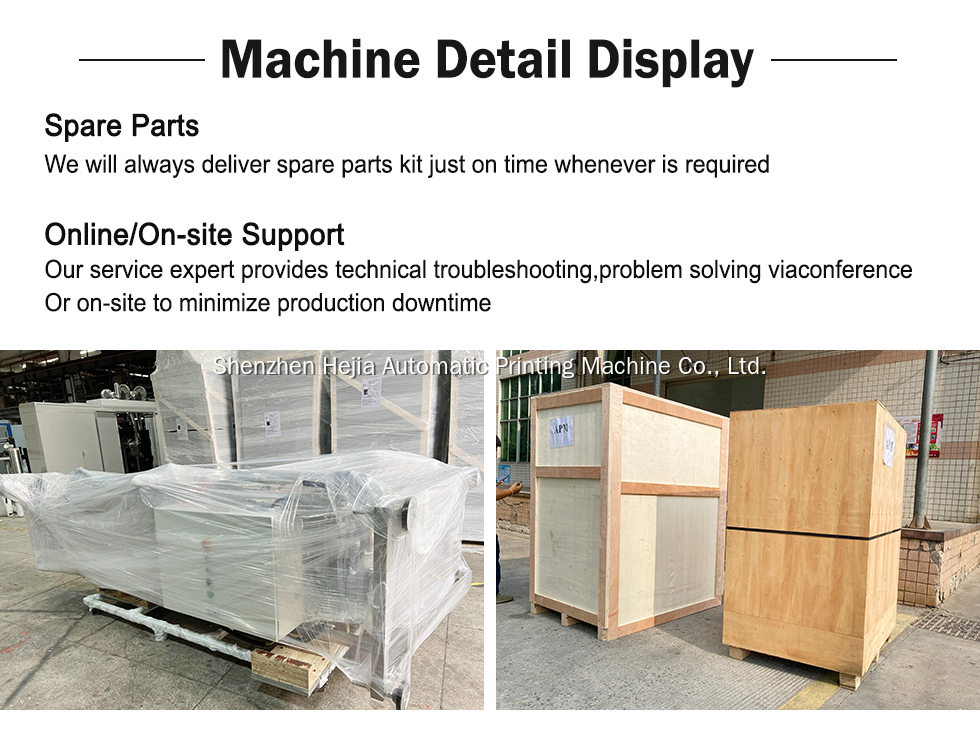

Included Spare Parts

Critical components like UV lamps, belts, blanket stickers, and forming rollers are included to minimize downtime.

Modular designs simplify component replacement, reducing maintenance costs.

1. What is the maximum printing efficiency?

The manual feeding model supports speeds of 60–80 pcs/min, while the automatic model can reach 100 pcs/min, depending on factors like tube size and print complexity.

2. Does it support different tube materials?

Yes, the machine is compatible with PP, PS, and PET tubes.

3. Can the printing quality of the equipment be guaranteed?

The machine is equipped with a precise printing control system and automatic adjustment function to ensure stable printing quality for each batch. Whether it is single-colour or multi-colour printing, the machine can accurately control the flow, thickness and distribution of ink, so that the printing effect is clear and without deviation. In addition, the automatic correction function can detect and correct the position of the pattern in real-time to avoid misalignment and blurring.

4. Is the operation user-friendly?

The machine features an intuitive touchscreen interface and requires minimal training, allowing operators to quickly adapt.

5. Can it adapt to plastic buckets of different sizes?

The printing range of the equipment can support a maximum printing diameter of 250mm and a printing height of 195mm, which is suitable for most common plastic buckets. The clamping system of the machine is adjustable to adapt to buckets of different sizes, and it is very easy to replace the size adapter.

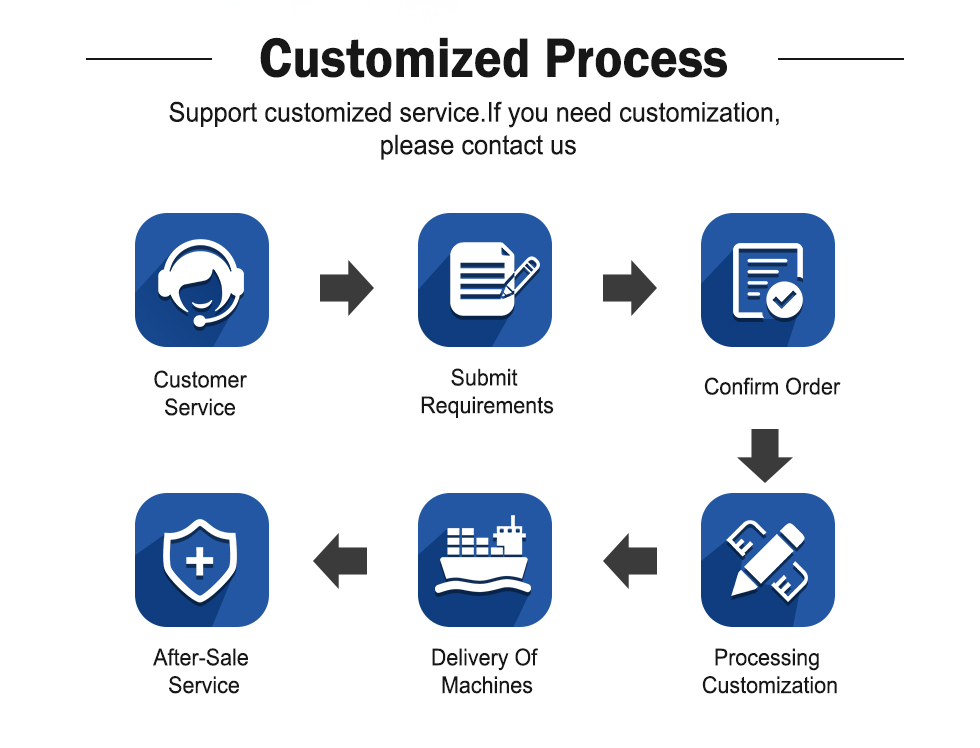

6. Is customized service provided?

Yes, we provide customized services, and customers can adjust the equipment configuration according to their own needs. For example, customers can choose different numbers of print heads, add automation devices, customize the size of the printing platform, etc. Customization services can help customers better adapt to the requirements of their production lines and improve production efficiency and printing quality.

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886