Hot Stamping Machine for bottle cap

The Automatic Hot Stamping Machine delivers precise foil stamping for cylindrical containers, combining compact design with industrial reliability—ideal for cosmetics, beverages, and pharmaceuticals.

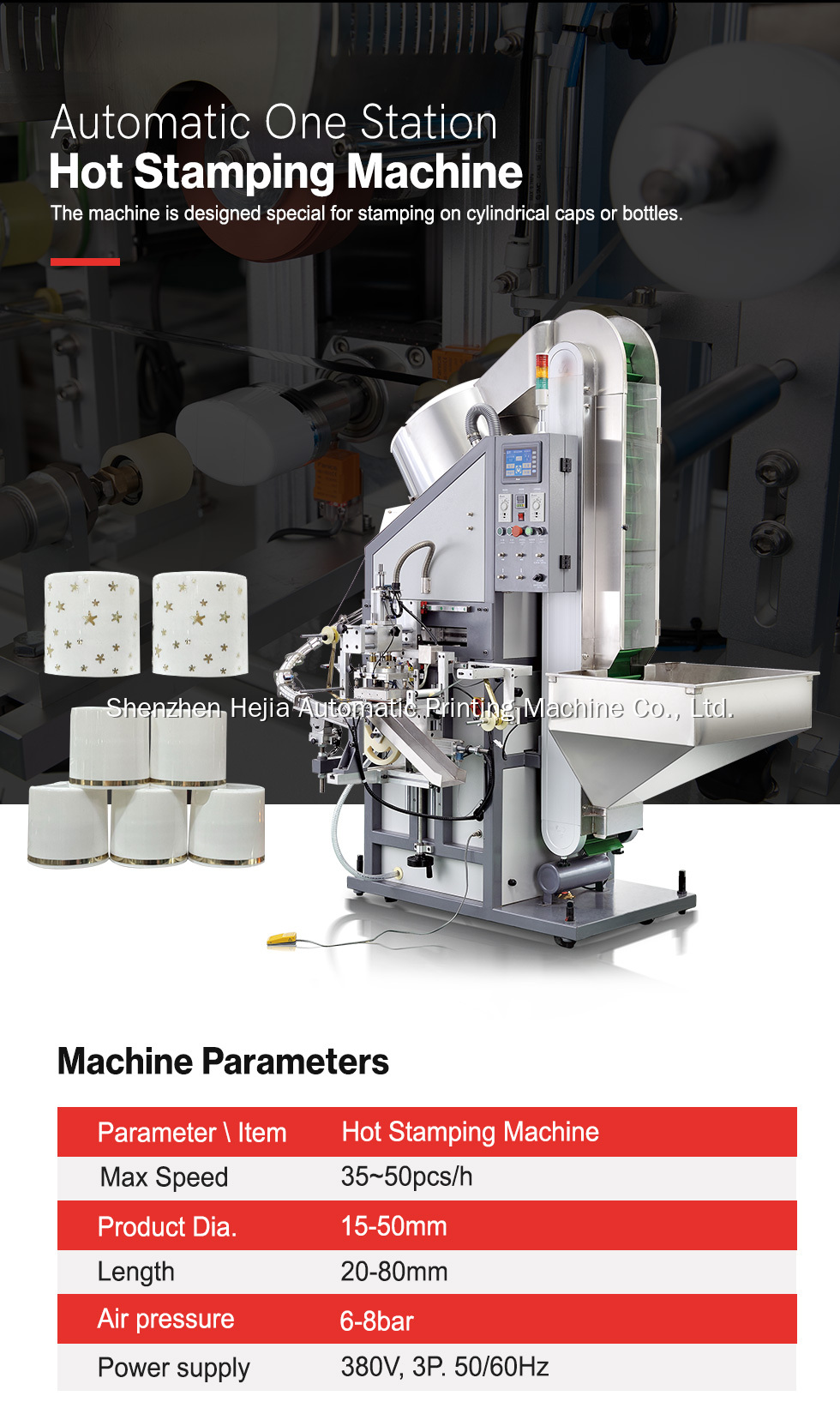

The Hot Stamping Machine for bottle cap is designed for cylindrical caps/bottles (Ø15-50mm, L:20-80mm). Featuring auto-loading, stamping, and unloading functions, it achieves speeds up to 50 pieces/hour with a space-saving rotary table structure.

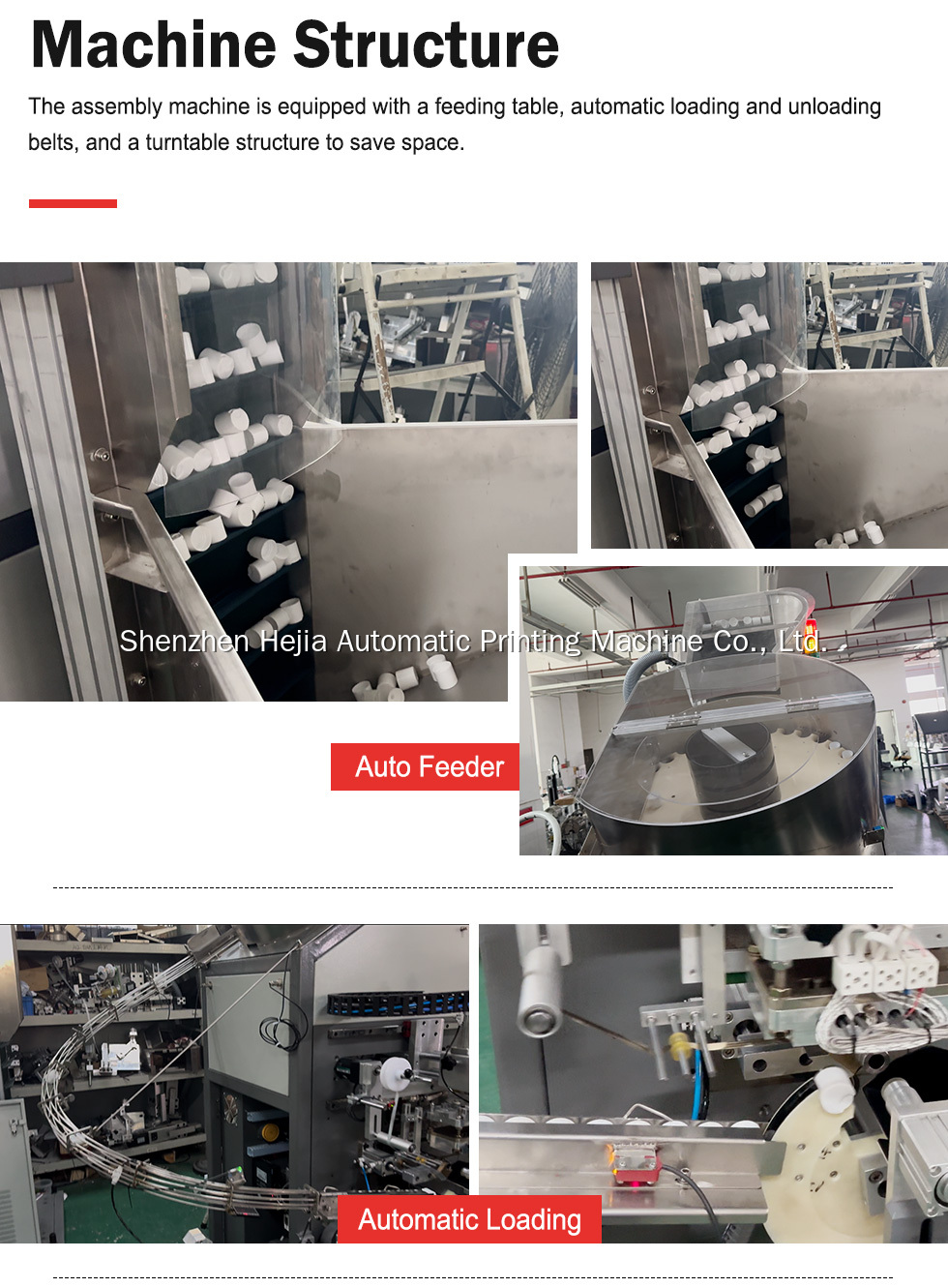

1. Automated Precision

Turntable feeding system ensures ±0.2mm stamping accuracy.

Ideal for logos, anti-counterfeit marks, and decorative foils.

2. Compact Flexibility

1.5㎡ footprint, suitable for small workshops.

Quick changeover (≤10 minutes) with universal fixtures.

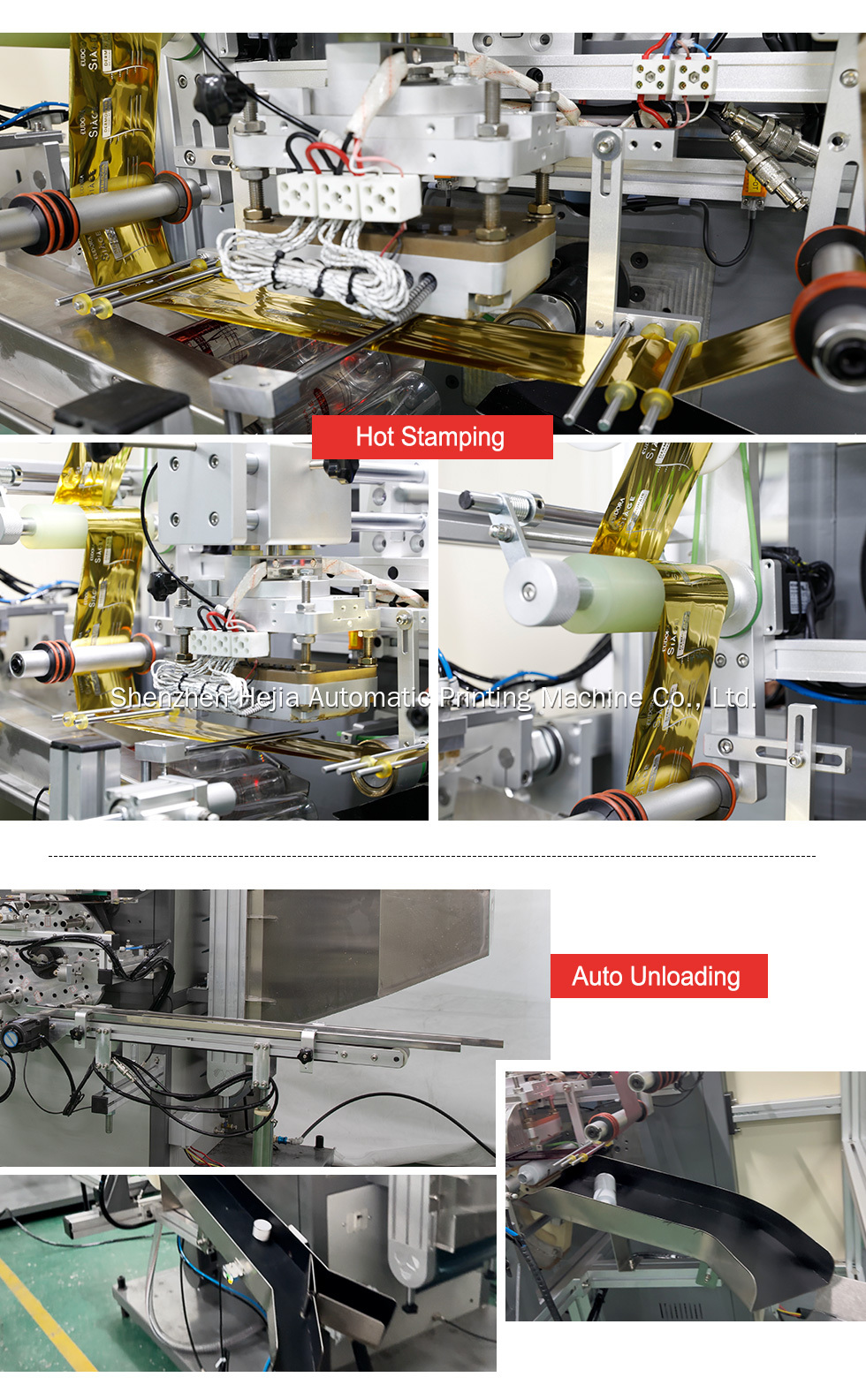

3. Industrial Reliability

380V/3-phase power, 6-8bar air pressure, <1% downtime.

High-temperature resistant stamping head (5-year lifespan).

1. Automated Precision

Turntable feeding system ensures ±0.2mm stamping accuracy.

Ideal for logos, anti-counterfeit marks, and decorative foils.

2. Compact Flexibility

1.5㎡ footprint, suitable for small workshops.

Quick changeover (≤10 minutes) with universal fixtures.

3. Industrial Reliability

380V/3-phase power, 6-8bar air pressure, <1% downtime.

High-temperature resistant stamping head (5-year lifespan).

| Parameter | Specification |

Production Speed | 35-50pcs/hour |

Product Diameter | 15-50mm |

Product Length | 20-80mm |

Air Pressure | 6-8Bar |

| Power Supply | 380V/3Ph/50-60Hz |

1. Cosmetic Caps: Metallic logo stamping and scratch-resistant coating.

2. Beverage Bottles: Foil-seal stamping and batch numbering.

3. Pharma Bottles: Anti-counterfeit labels and alcohol-resistant foils.

Q1: Can the bottle cap hot stamping machine handle non-round caps?

✅ Yes, with custom fixtures (Ø15-50mm, L:20-80mm).

Q2: What is the changeover time for this machine?

✅ The Automatic One Station Hot Stamping Machine achieves ≤10-minute changeovers.

Q3: Does it support multi-position stamping?

✅ Single-station design for precise stamping; multi-position requires sequential operation.

Q4: Is the machine safety-certified?

✅ CE-compliant with emergency stop and safety guards.

Q5: What is the MOQ?

✅ MOQ 500pcs for small-batch production.

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886