Automatic Closure Printing Machine

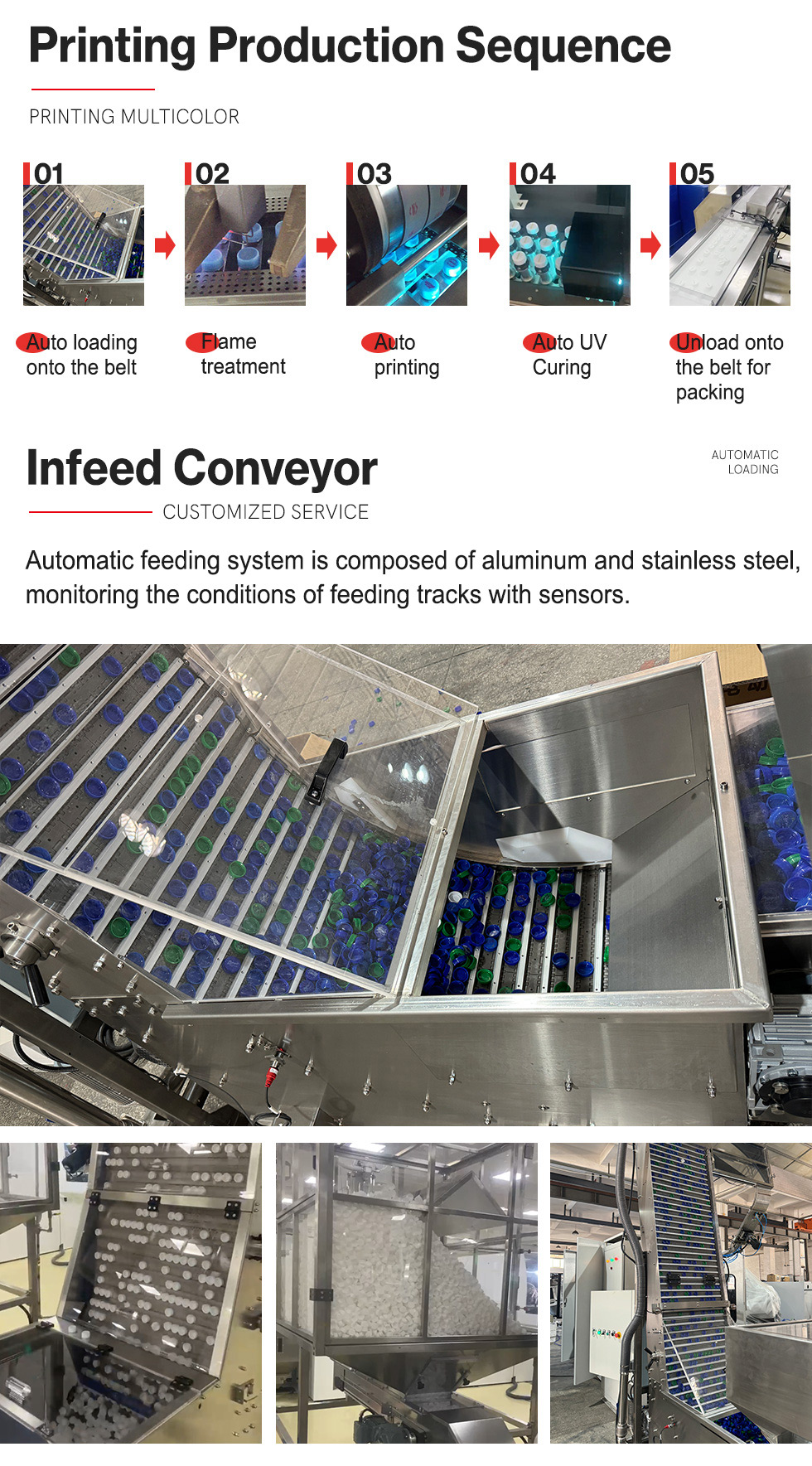

The APM-CAP2L Automatic Closure Printing Machine is an innovative and efficient solution for high-speed printing on plastic caps made of PP or PE materials with diameters ranging from 28mm to 38mm. Designed for industries like food, beverage, and cosmetics, this machine delivers exceptional performance with a production speed of up to 1000 caps per minute.

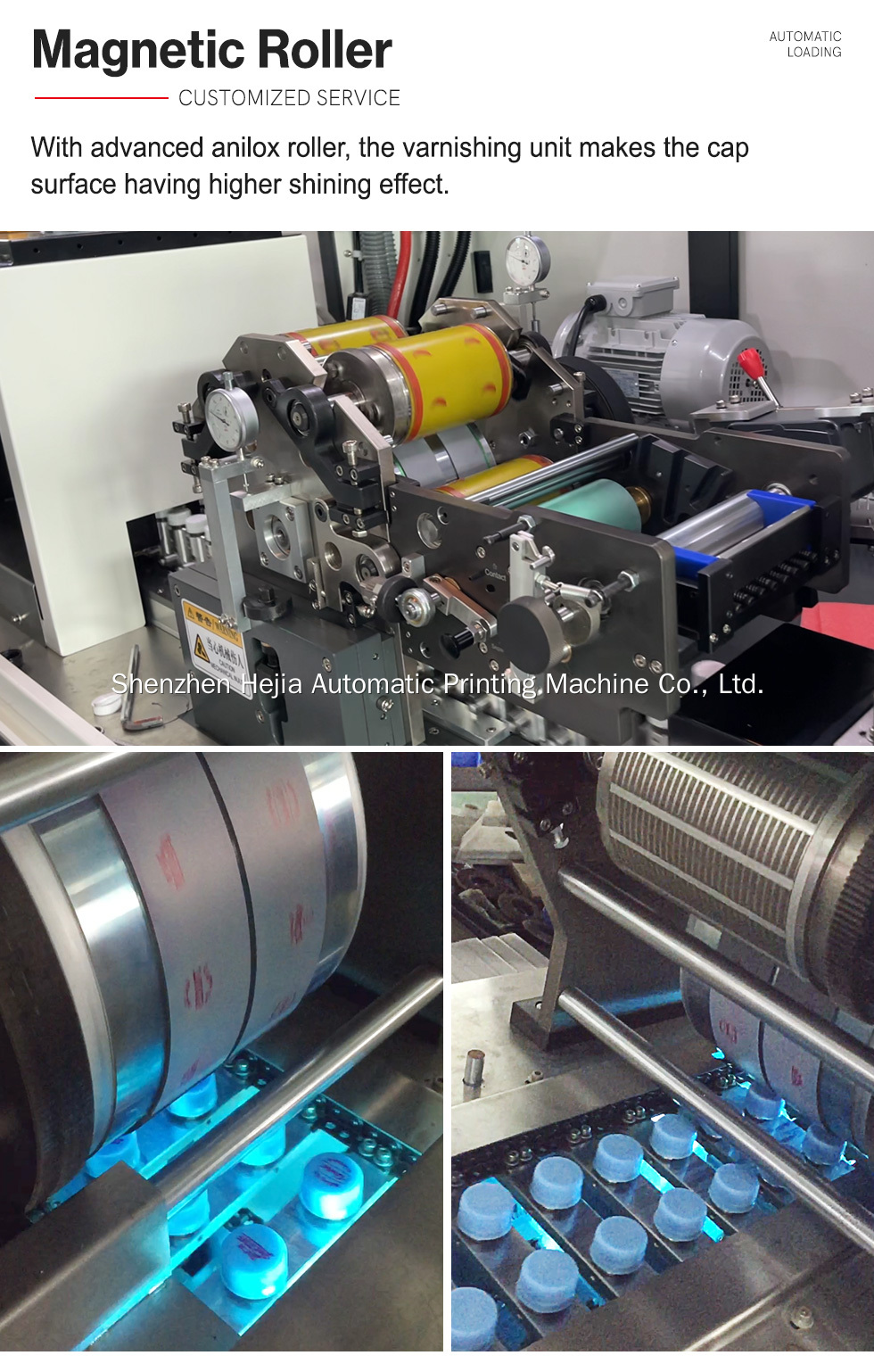

Equipped with advanced flame treatment heads, it ensures superior ink adhesion and enhanced print quality. The machine features a USA HERAEUS UV system with automatic temperature control to prevent overheating and ensure consistent curing. Its high-precision magnetic rollers and tailor-made mandrels guarantee sharp, accurate prints, supporting 1-2 color printing for versatile branding needs.

Built with durable components from trusted international brands like OMRON, HERAEUS, and SITI, the APM-CAP2L ensures long-term reliability and low maintenance costs. Whether for large-scale production or intricate designs, this machine provides a perfect blend of speed, quality, and flexibility, making it an ideal choice for businesses looking to enhance productivity and maintain superior print standards.

The APM-CAP2L Automatic Closure Printing Machine is a state-of-the-art printing solution designed for high-speed and precision printing of PP and PE caps with diameters ranging from 28mm to 38mm. Built with advanced technology, this machine delivers exceptional quality and efficiency, making it ideal for industries such as food packaging, beverages, pharmaceuticals, and cosmetics.

Equipped with a robust USA-brand UV system, high-precision magnetic rollers, and tailor-made mandrels, the APM-CAP2L ensures seamless operation for demanding production needs. With its 1000 pcs/min maximum speed, this machine is perfect for businesses looking to enhance productivity while maintaining high printing standards.

High-Speed Printing

The machine offers a maximum speed of 1000 pcs/min, significantly reducing production time while maintaining consistent quality.

Advanced Surface Treatment

Integrated flame heads ensure efficient surface treatment of caps, improving ink adhesion and overall print quality.

Precision Printing

Tailor-made printing fixtures and high-precision magnetic rollers ensure accuracy, providing sharp, high-resolution prints.

Efficient UV Curing System

The USA HERAEUS UV system features automatic temperature control and extraction systems, maximizing lamp efficiency and avoiding overheating.

Customizable Printing Options

Supports 1-2 color printing, catering to a wide range of branding and product design requirements.

Durable and High-Quality Components

Features premium components from trusted international brands such as OMRON, HERAEUS, and SITI for reliable and long-lasting operation.

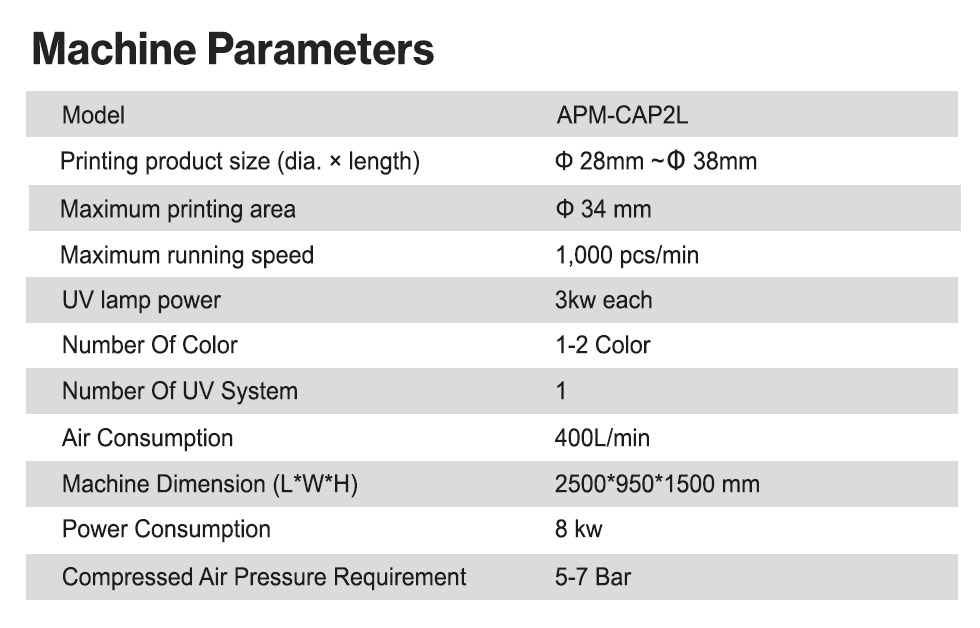

| Parameter | Closure Printing Machine |

Maximum Running Speed | 1000 pcs/min |

Power Requirement | 380V, 3P, 50Hz |

Weight | 1950 kg |

Machine Dimensions (L x W x H) | 2500X950X1500 mm |

Printing Product Size | 28-38mm |

Warranty | 1 Year |

Bran | APM |

Applications:

Cap Printing for Beverages

Suitable for printing logos, designs, or information on caps for bottled water, soft drinks, juices, and other beverages.

Cosmetic Packaging

Perfect for branding cosmetic product closures such as lotion caps, cream jar lids, and makeup packaging.

Food Packaging

Ideal for caps used in food packaging, such as condiments, sauces, and oil bottles.

Pharmaceutical and Healthcare

Used for printing on caps for medical products, supplements, and healthcare packaging to meet safety and branding requirements.

Household Products

Suitable for closures on cleaning agents, detergents, and other household product containers.

Industries:

Food and Beverage Industry

Ensures high-speed and precise printing for branding caps used in various beverage and food containers.

Cosmetics and Personal Care

Offers a solution for detailed, high-quality branding on closures of cosmetic and personal care products.

Pharmaceuticals

Provides clean, precise printing for pharmaceutical caps, ensuring compliance with industry standards.

Consumer Goods Manufacturing

Tailored for a wide range of industries producing caps for everyday household and consumer products.

Packaging Industry

Integrates seamlessly into automated production lines for large-scale cap printing in packaging plants.

1. Conveying System Maintenance

Regularly check and tighten conveyor belts to ensure smooth operation.

Clean residue and debris to prevent damage to the belt and motor.

Inspect sensors and stepper motors regularly for wear and tear.

2. Printing Component Maintenance

Calibrate mandrels and magnetic rollers periodically for precision.

Clean the flame heads and printing units to avoid blockages or ink buildup.

Replace worn printing fixtures to maintain accuracy.

3. UV Curing System Maintenance

Regularly inspect and clean UV lamps to maintain curing efficiency.

Monitor the automatic temperature control system to prevent overheating.

Replace UV lamps when required to ensure consistent curing quality.

4. Control System Maintenance

Update PLC software and back up data regularly.

Inspect touch screens and relays to avoid connectivity issues.

Maintain a clean environment around electrical components to prevent dust accumulation.

Q1: What types of caps can the APM-CAP2L print on?

A: The machine is designed to print on caps made of PP or PE material, with diameters ranging from φ28mm to φ38mm.

Q2: What is the maximum production speed?

A: The APM-CAP2L can produce up to 1000 caps per minute, making it one of the fastest in the industry.Q3: How does the flame treatment enhance printing quality?

A: The integrated flame heads improve ink adhesion by treating the surface of caps, ensuring sharp and durable prints.Q4: Can the machine handle multi-color printing?

A: Yes, the machine supports 1-2 color printing, offering flexibility for branding and design.Q5: What safety features are included?

A: The machine features emergency stop buttons, automatic temperature controls, and high-quality components from trusted brands to ensure safe and stable operation.Q6: How is the machine maintained?

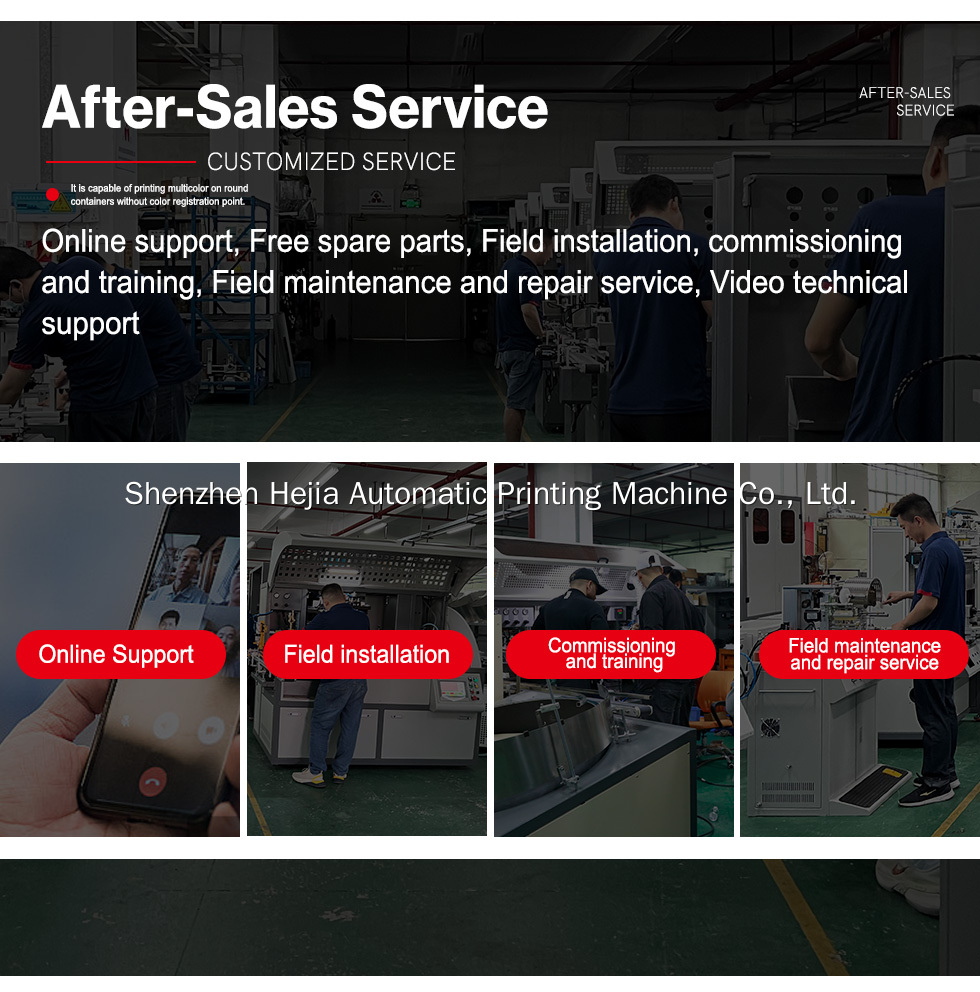

A: Regular maintenance includes cleaning the UV lamps, calibrating rollers and mandrels, and inspecting the control and conveying systems to ensure optimal performance.Q7: Is training provided for machine operation?

A: Yes, training and inspection are conducted in our Guangzhou factory. On-site commissioning by a technician is also available upon request.Q8: Can this machine be customized?

A: Yes, the APM-CAP2L can be tailored to specific production needs, including configuration adjustments and process customization.

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886