APM PRINT - Automatic cap printing machine round cylindrical caps tube foil hot stamping machine

Since inception, we have been constantly upgrading the manufacturing technologies.Thanks to those technologies, product performance has also improved a lot. It has a wide application and now can be found in the field(s) of Heat Press Machines.

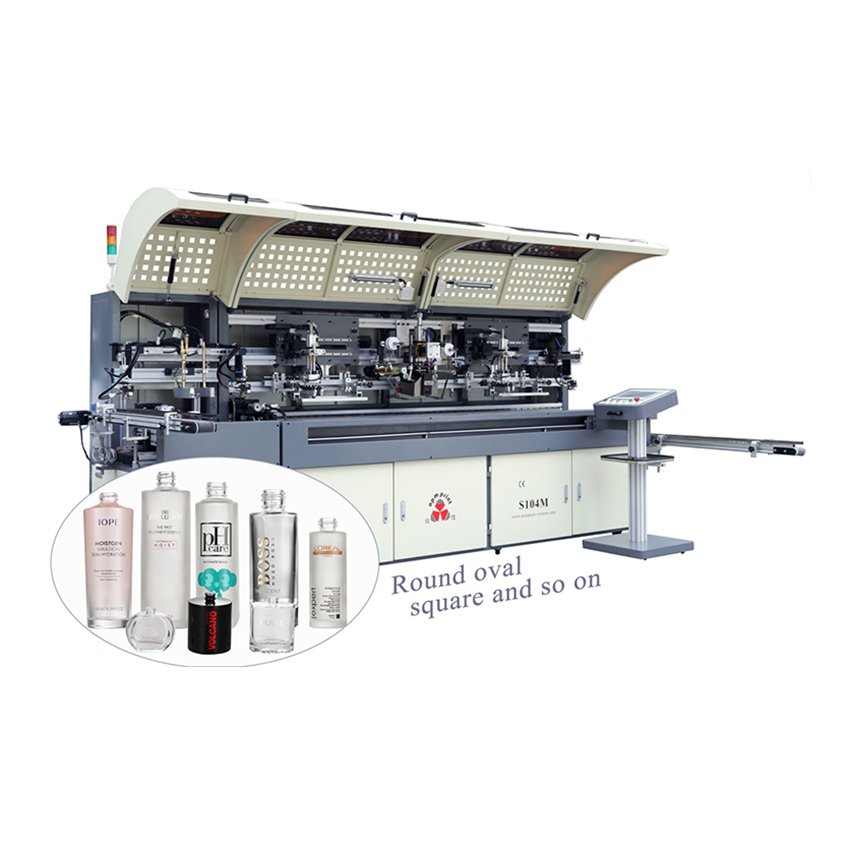

The hot stamping press contains a heating element that heats up the die or type; the marking cycle starts when the press engages the heated die or type with the foil and transfers the ink from the foil carrier onto the part to be marked. Hot stamping is very flexible in that this process is used to mark a wide variety of different materials. Hot stamping machine for plastic, leather, rubber, and fabrics are just some of the materials automatic hot stamping machines mark quite well. Hot stamping is a very popular option for monogramming and personalization.

Hot stamp machines, also known as hot foil coders, employ uncomplicated and dependable mechanical mechanisms. Through this technique, heated type is firmly pressed onto the desired surface using a ribbon or foil. This results in the transfer of pigment from a polyester carrier onto the product, creating a durable and smudge-resistant mark of superior quality. These machines are commonly utilized for imprinting fixed codes like date codes, lot numbers, expiration dates, and product codes on labels or packaging materials.

In hot stamp coders, type characters, dies, or wheel numbering units are typically engraved or cast from metal or silicone. To change the code, the operator must manually change the type characters or slugs. With basic training, it is relatively easy to accomplish this task.

In order to make the mark, the block of characters/logo is heated and stamped down with pneumatic air pressure. The raised surface of the characters makes contact with the pigmented foil/ribbon, pressing it into the substrate.

As a result of this technology, characters can last for tens of thousands of impressions over the course of a long period of time. The technology is widely used in the food and pharmaceutical industries as it provides a clean and simple coding solution. Additionally, hot stamp coders work well in dusty and sticky manufacturing environments, which are difficult for delicate non-contact inkjet coders to handle.

Hot stamping machines are able to adjust for various types of dies and marking type. Magnesium, brass, and steel are some of the materials typically used to make hot stamping type and dies, depending on your budget as well as the number of items that need to be stamped.APM PRINT has extensive experience in designing and recommending the best materials for your particular application.

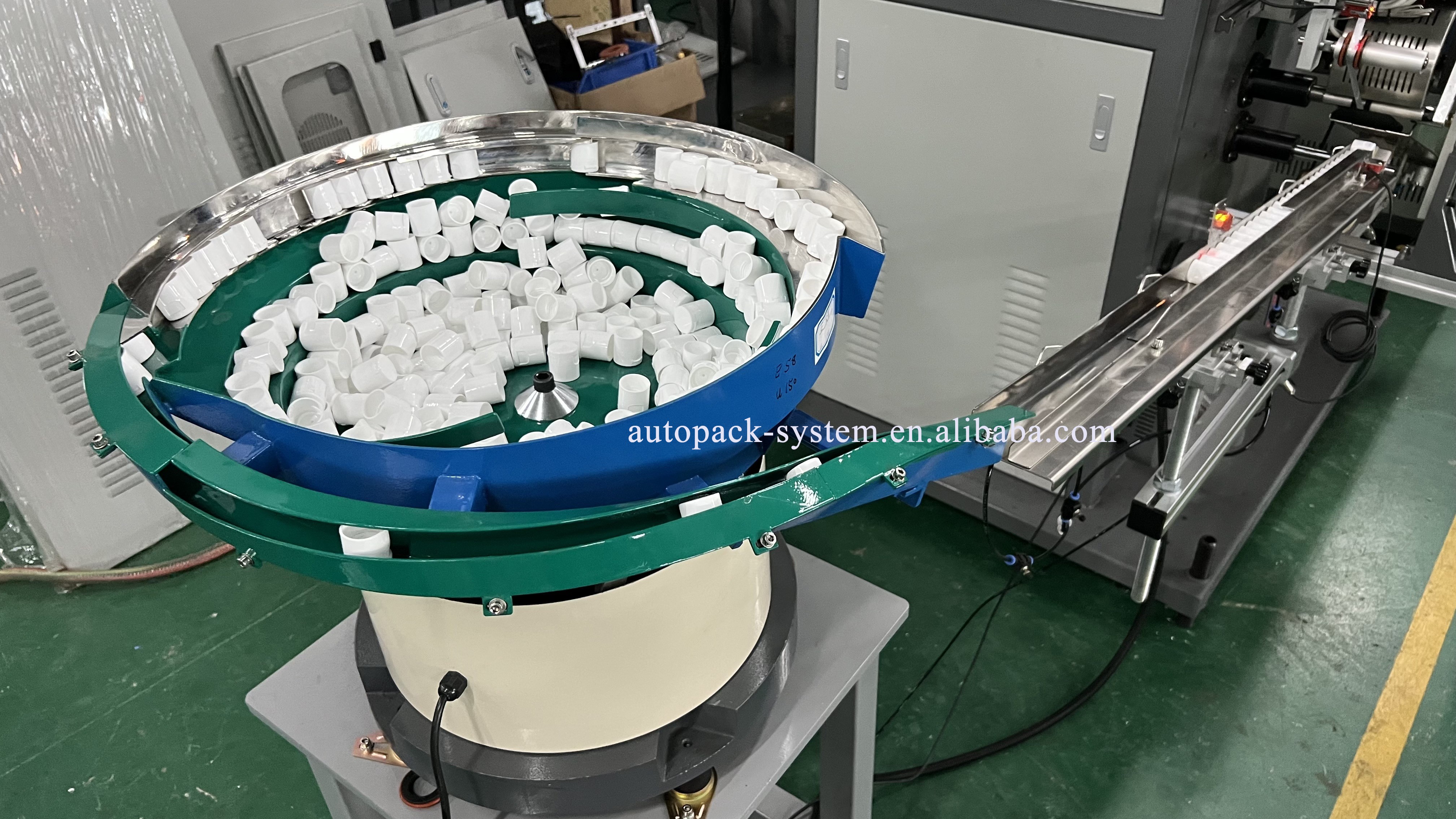

Combining the efforts of all our staff and keeping up with the trend, Shenzhen Hejia Automatic Printing Machine Co., Ltd. has developed the version of Automatic cap screen printing machine round cylindrical caps tube hot stamping machine cap printer . It is borne with the updated features and is expected to create values and benefits for customers. Technological innovation is the fundamental reason for Shenzhen Hejia Automatic Printing Machine Co., Ltd. to achieve sustainable development. Shenzhen Hejia Automatic Printing Machine Co., Ltd. always stick to the core value of 'integrity and honesty' since established. We will strive forward to manufacture and provide the fine-quality products and try hard to provide the best services for our customers.

| Type: | Heat Press Machine | Applicable Industries: | Manufacturing Plant, Printing Shops |

| Condition: | New | Plate Type: | Letterpress |

| Place of Origin: | Guangdong, China | Brand Name: | APM |

| Model Number: | H104A | Usage: | Cap and Bottle Stamping |

| Automatic Grade: | Automatic | Color & Page: | single color |

| Voltage: | 380V | Weight: | 1000 KG |

| Warranty: | 1 Year | Key Selling Points: | Easy to Operate |

| Machinery Test Report: | Provided | Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year | Core Components: | Motor, PLC |

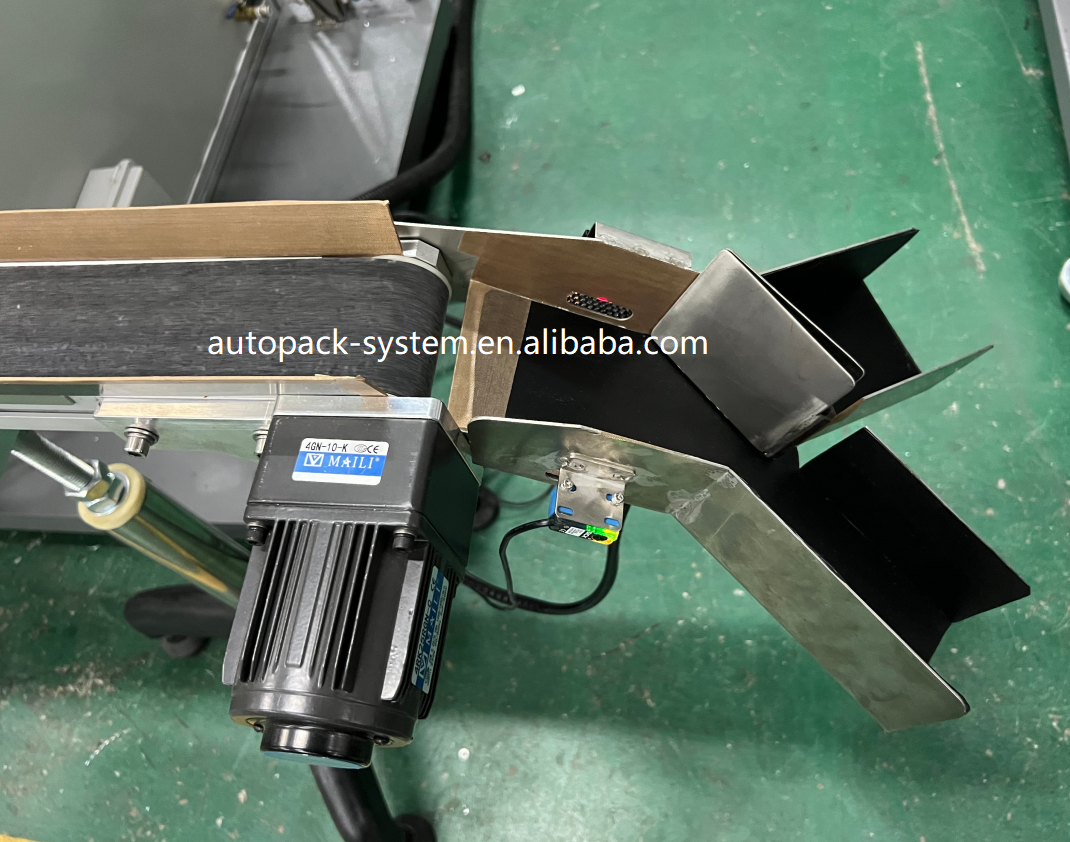

| Driven Type: | Pneumatic | Product Name: | Cap Hot Stamp Printing Machine |

| Application: | Cap and Bottle Stamping | Printing Speed: | 40-55pcs/min |

| Printing Size: | Dia.15-50mm & Len. 20-80mm | After Warranty Service: | Video technical support |

| After-sales Service Provided: | Video technical support | Marketing Type: | Ordinary Product |

| Certification: | CE Certificate |

Product Name | Auto Round Cap Hot Stamping Machine |

Printing speed | 40~55pcs/min |

Printing diameter | 15-50mm |

Printing length | 20-80mm |

Air pressure | 6-8Bar |

Power | 380V, 3P 50/60HZ |

General Description

Company Profile

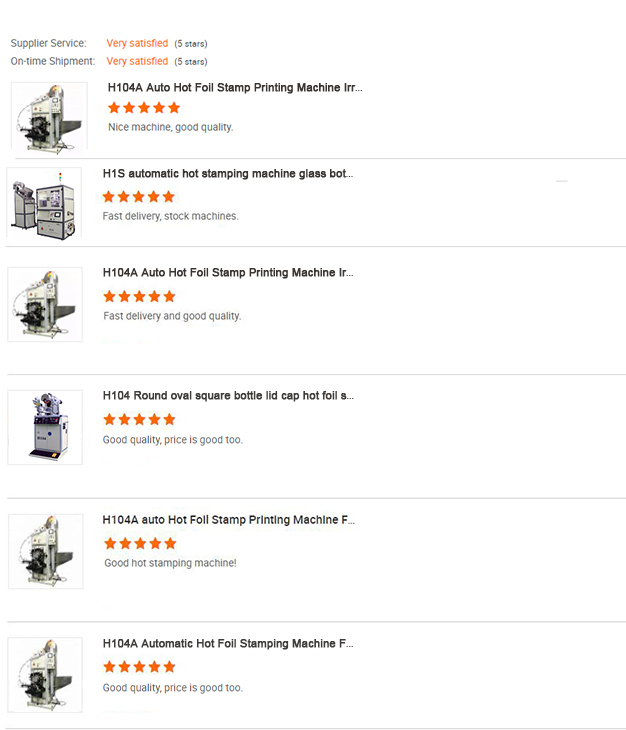

Q:Can we print samples to check the quality?

A:yes

Q:Is there operation training?

Yes, we offer free training on how to install and use the machine, and more importantly, our engineers can go overseas to repair the machine!

Q:How long warraty of the machine?

A:year+lifelong technical supports

Q:Which payment item do you accept?

A: L/C (100% irrevocable sight) or T/T (40% deposit + 60% balance before delivery)

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886