Helmet Spraying Painting Machine Coating Line With Water Based Booth And Drying Oven

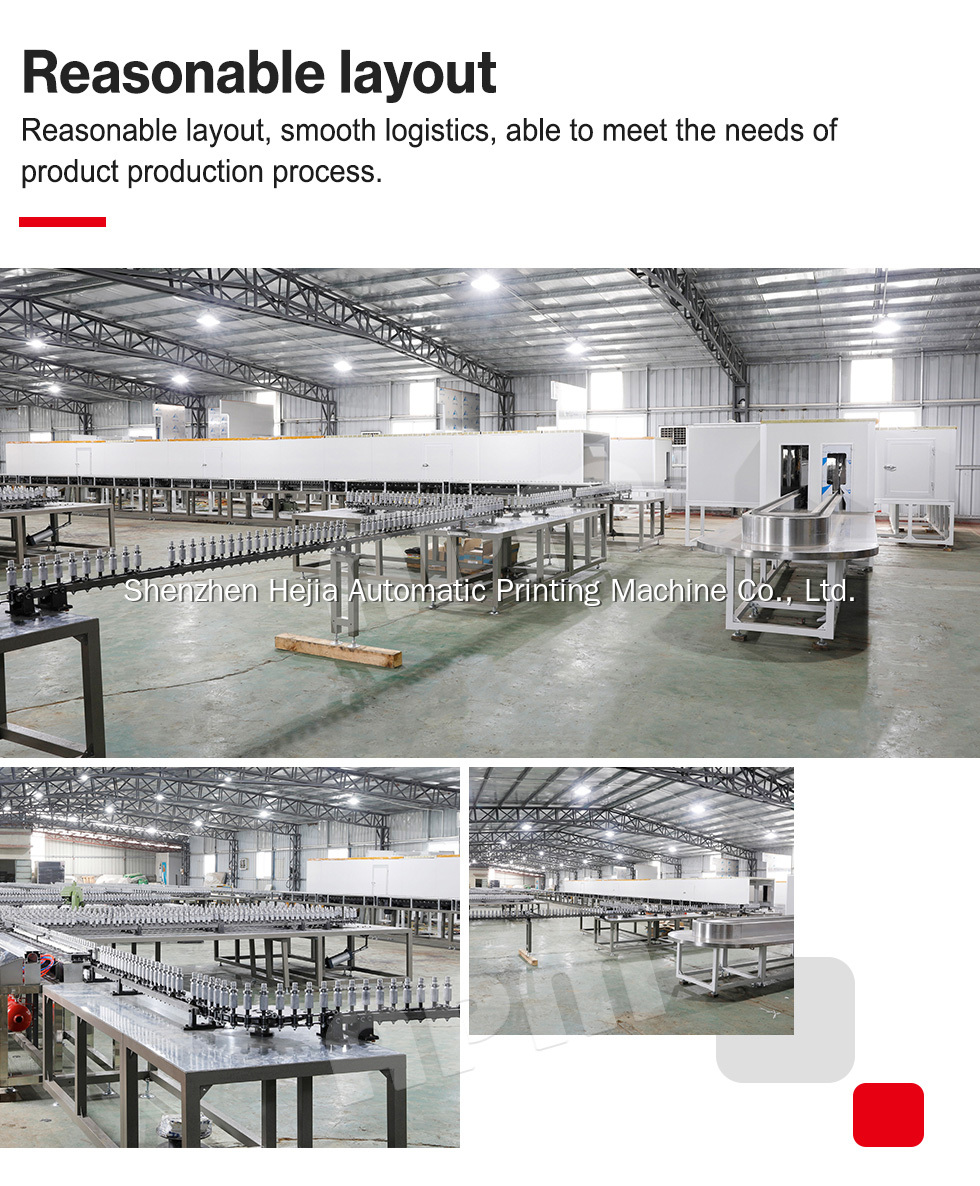

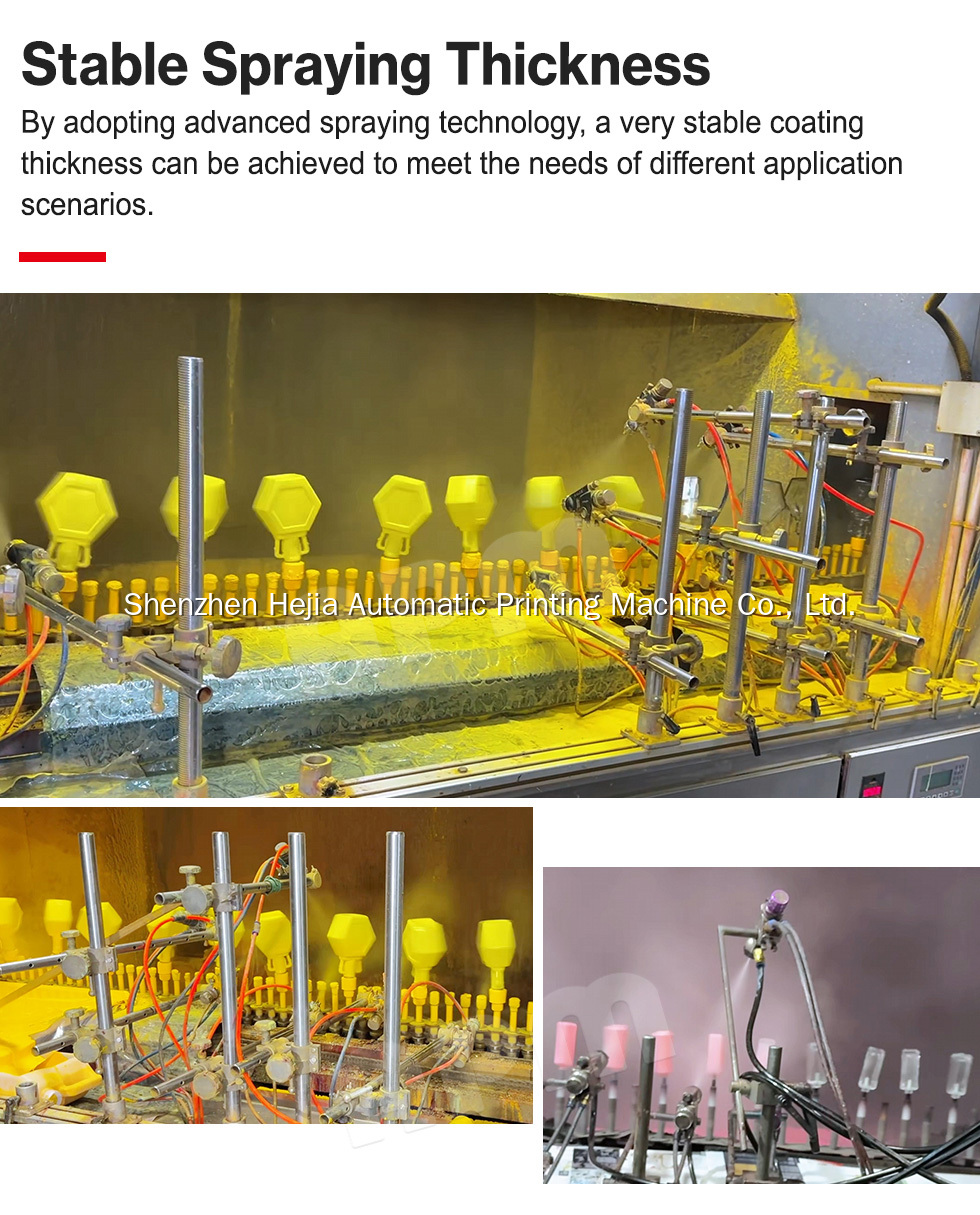

The APM Helmet Spraying Painting Machine Coating Line is a high-efficiency, automated solution designed for precise and uniform coating of helmets and plastic components made from ABS, PP, and PC materials. Equipped with a water-based spray booth and high-performance drying oven, it ensures eco-friendly, durable, and high-gloss finishes while minimizing material waste and VOC emissions. Its multi-angle robotic spraying system provides full coverage, even on complex helmet shapes, while the PLC-controlled automation enhances production efficiency and consistency. With a customizable design, energy-saving operation, and easy maintenance, this system is ideal for motorcycle, bicycle, sports, and industrial helmet manufacturers, helping businesses achieve superior surface finishing with reduced operational costs.

The APM Helmet Spraying Painting Machine Coating Line is a high-precision, fully automated system designed for helmets and plastic components made from ABS, PP, and PC materials. Featuring a water-based spray booth and an advanced drying oven, this line ensures uniform coating, high efficiency, and eco-friendly operation. It is widely used in motorcycle, bicycle, sports, and industrial helmet manufacturing, providing a durable, scratch-resistant, and high-gloss finish while minimizing material waste. With its PLC-controlled automation and multi-angle spraying capability, this system delivers consistent quality, reduces labor costs, and enhances production efficiency.

✅ Automated Spraying System – Ensures precision and uniform coating coverage.

✅ Water-Based Booth – Eco-friendly, reducing VOC emissions and improving workplace safety.

✅ High-Efficiency Drying Oven – Speeds up curing, enhances adhesion, and prevents defects.

✅ Customizable Design – Adjustable for different helmet sizes and coating types.

✅ Multi-Angle Spraying – Ensures even coating on complex helmet shapes.

✅ Energy-Saving & Cost-Effective – Reduces material waste and operational costs.

🔹 Brand: APM

🔹 Model: Helmet Spraying Painting Machine Coating Line

🔹 Customization: Available

🔹 Coating Type: Water-based

🔹 Drying Method: High-efficiency drying oven

🔹 Material Compatibility: ABS, PP, PC plastics

🔹 Control System: PLC automation with touch-screen operation

🔹 Operation Mode: Fully automated, high-precision spraying

🔹 Application: Helmets, cosmetic boxes, plastic caps, automotive accessories

✅ Motorcycle & Bicycle Helmets – Ensures durable and high-gloss coatings.

✅ Sports & Industrial Safety Helmets – Provides long-lasting protection and aesthetics.

✅ Automotive Accessories – Suitable for helmet shells and plastic trims.

✅ Cosmetic Packaging – Used for caps, boxes, and other plastic components.

✅ Regular Cleaning – Ensure booth filters are clean for optimal performance.

✅ Routine Calibration – Maintain spraying accuracy and consistency.

✅ Technical Support – On-site installation, training, and remote troubleshooting.

✅ Spare Parts Supply – Fast replacement service to minimize downtime.

✅ Preventive Maintenance – Periodic inspections to maximize equipment lifespan.

1. What helmet materials are compatible with this system?

It is designed for ABS, PP, and PC plastic helmets, ensuring strong adhesion and durability.

2. What are the advantages of a water-based spray booth?

It reduces VOC emissions, is environmentally friendly, and ensures safe workplace conditions.

3. Can this system be customized?

Yes, we offer customized solutions based on helmet size, coating type, and production capacity.

4. How does the drying oven improve coating quality?

It speeds up curing, enhances adhesion, and prevents defects like cracking or peeling.

5. What industries use this coating line?

It is widely used in helmet manufacturing, automotive, sports, and industrial safety sectors.

6. What is the system's operational efficiency?

The automated system ensures high-precision coating, reduces material waste, and lowers labor costs.

7. How is the system controlled?

It is equipped with a PLC + touchscreen interface, allowing for easy operation and programming.

8. What are the installation and maintenance requirements?

The plug-and-play design ensures quick installation, and modular components make maintenance easy.

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886