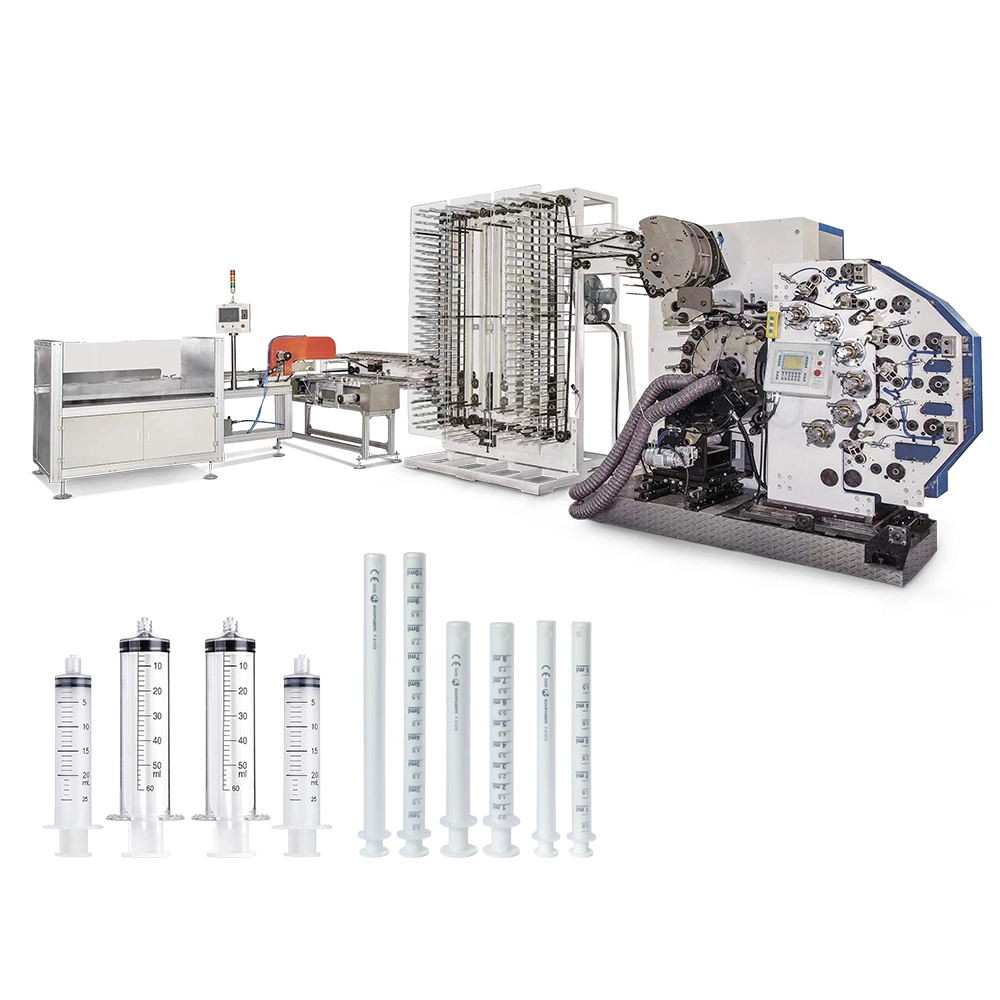

Automatic syringe offset printing machine

The syringe offset printing machine is a highly efficient printing device designed for the medical industry. It is mainly used for high-precision marking and printing on the surface of syringes. It uses advanced offset printing technology to ensure that the scale, brand logo, production date and other information of each syringe are clearly and stably displayed. The maximum printing speed of the syringe offset printer can reach 90 pieces/minute, which is suitable for large-scale production needs.

The Plastic Tube Printer is a high-efficiency 4-color printing machine designed for PP, PS, and PET tubes (Ø25-55mm, 30-220mm length). It integrates corona treatment, varnishing, and UV curing, which is ideal for the cosmetics, pharmaceuticals, and food packaging industries.

1. Fast printing speed

The maximum printing speed of the syringe offset printing machine can reach 90 pieces/minute, ensuring efficient production capacity, especially suitable for large-scale production needs, and improving overall production efficiency.

2. Multi-color printing capability

The syringe offset printing machine supports 4-color printing, different markings, scales and brand logos, increasing the visual appeal and brand recognition of the product. Supports printing of multiple materials such as PP, PS, PET, etc., adapts to syringes of different materials, and ensures the wide applicability of the equipment.

3. Multiple diameter ranges

The syringe offset printing machine can adapt to the diameter range of 25-55mm, supports the production of syringes of different specifications, and adapts to different market needs. Supports a tube length range of 30-220mm, which can meet the printing needs of syringes of different sizes, and improves the versatility and application range of the equipment.

4. Multiple printing widths and lengths

The maximum printing width of the syringe offset printing machine reaches 172mm, ensuring high-quality pattern and text printing on larger surfaces, and the maximum printing length is 190mm, providing higher precision and flexibility, ensuring clear and fine printing effects on longer syringe surfaces.

Specification | |

Max Printing Speed | 90 pcs/min |

Printing Colors | 4 colors |

Tube Diameter Range | Ø25-55mm |

Tube Length Range | 30-220mm |

Max Printing Width | 172mm |

Max Printing Length | 190mm |

| Materials | PP, PS, PET |

1. Cleaning and maintenance

After each use, clean the ink residue on the ink roller and printing cylinder in time to prevent ink accumulation from affecting the printing quality. Use professional cleaning agents and avoid using highly corrosive cleaning fluids.

2. Regular inspection

Check the working condition of the drive motor, belts, gears and other transmission parts to ensure that they are not loose, worn or damaged. Regularly check and replace lubricating oil to ensure the smooth operation of the mechanical transmission part.

3. Calibration and adjustment

Check and calibrate the alignment between the printing head and the surface of the syringe to ensure that each printing can be accurate and in place to avoid pattern and text deviation.

4. Check the electrical system

Regularly check whether the lines in the electrical system are aging or damaged, ensure the electrical safety of the equipment, and ensure the various safety devices of the machine, such as overload protection, emergency stop button, etc.

5. Prevent dust

Maintain good ventilation and cleanliness in the production area to prevent dust, oil, etc. from entering the machine. Clean the outside of the machine regularly to avoid dirt accumulation affecting equipment performance.

Delivery: 45 working days after deposit.

Payment: 30% deposit, 70% balance before shipment.

Warranty: 1-year full machine warranty.

1. Is the Automatic Syringe Offset Printing Machine suitable for standard syringes?

✅ Yes, it is designed for standard syringes (Ø5-30mm, 50-200mm length), printing dose scales and batch codes with high precision.

2. What is the printing accuracy?

✅ CCD vision alignment ensures ≤±0.02mm accuracy for critical markings.

3. Can it handle multi-batch production?

✅ Split ink systems allow batch switching in 5 minutes without contamination.

4. Is cleaning and maintenance complicated?

✅ Modular design enables quick cleaning, with IQ/OQ/PQ documentation for GMP compliance.

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886