Automatic servo bottle screen printer

The Automatic Servo Bottle Screen Printer offers 1200-2400 pcs/hr speed, 15-minute changeover, and CE-certified safety for cylindrical containers using solvent/thermoplastic inks.

The Automatic Servo Bottle Screen Printer is a single-color screen printing machine designed for cylindrical containers (bottles/jars), supporting solvent and thermoplastic inks. With multi-axis servo robots, auto loading/unloading, and IR drying, it achieves speeds of 1200-2400 pcs/hr for the cosmetics, food, and pharmaceutical industries.

1. Automatic loading system with multi-axis servo robot. Bottle standing on the belt.

2. Robot transfer system.

3. Automatic printing system with servo-driven

4. With solvent ink or thermoplastic ink printing (need to leave clamp space if using solvent ink

printing)

5. Super quick and easy changeover from one product to another.

6. All parameters are automatically set simply on the touch screen. Product change is 15 minutes only per

colour.

7. Automatic unloading with servo robot. Bottle standing unloading.

8. Safety operation with CE.

9. With IR drying bottle surface on unloading belt.

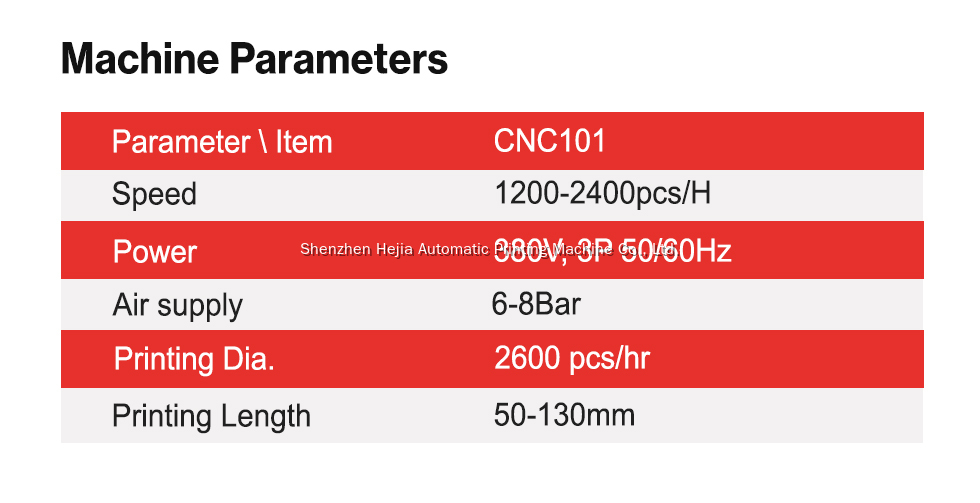

Parameter \ltem | Automatic servo bottle screen printer |

Applicable Containers | Cylindrical bottles/jars |

Printing Colors | Single-colour (expandable) |

Bottle Diameter Range | Ø10-60mm |

Bottle Length Range | 50-130mm |

Power supply | 380V, 3-phase, 50/60Hz |

| Air Pressure | 6-8bar |

| Drying Method | IR Drying |

1. Cosmetic Bottles: Logo stamping on perfume bottles, embossed jar lids.

2. Beverage Bottles: Metallic branding on premium water bottles.

3. Pharmaceuticals: Anti-tamper stamps on medicine bottles.

4. Promotions: Full-wrap foil designs for limited editions.

1. Can the Automatic servo bottle screen printer print multi-colours?

✅ Designed for single-colour, but expandable to multi-colour.

2. Does the Automatic servo bottle screen printer print support solvent inks?

✅ Yes, clamp space is required for solvent inks.

How long is mould changeover?

✅ 15 minutes per colour with a modular design.

3. What is the Automatic servo bottle screen printer print speed?

✅ Up to 1200-2400 pcs/hr, adjustable based on bottle type.

4. Does the Automatic servo bottle screen printer print support irregular bottles?

✅ Optimized for cylindrical containers; custom fixtures required for irregular shapes.

5. Is the Automatic servo bottle screen printer print CE-certified?

✅ Yes, with emergency stop and self-diagnosis features.

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886