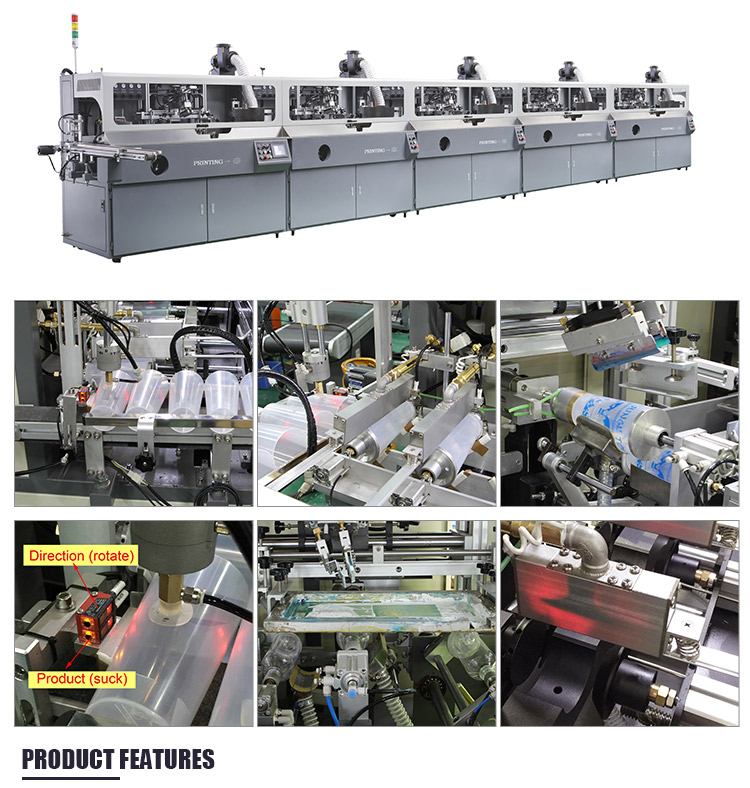

APM PRINT - S102 1-8 colors automatic bottle printing machine, flame treatment, UV drying system Auto Screen Printer

Shenzhen Hejia Automatic Printing Machine Co., Ltd. after long-term market research, we have created a brand-new product that is different from its peers. And precisely because of the clear core selling point of S102 1-8 colors automatic bottle printing machine, flame treatment, UV drying system, not only does the product have a high reputation among customers, but also allows the product to have a high degree of intimacy among customers. In this technology-driven society, 1997 focus on improving R&D strength and keep developing new technologies so as to increase our competitiveness in the industry. We aim to become one of the leading enterprises in the market.

| Plate Type: | Screen Printer | Applicable Industries: | Manufacturing Plant |

| Condition: | New | Place of Origin: | Guangdong, China |

| Brand Name: | APM | Usage: | bottle printer |

| Automatic Grade: | Automatic | Color & Page: | Multicolor |

| Voltage: | 380V | Dimensions(L*W*H): | 2500x1420x1700mm |

| Weight: | 2200KG | Certification: | CE Certification |

| Warranty: | 1 Year | After-sales Service Provided: | Online support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Engineers available to service machinery overseas |

| Application: | Bottles | Printing speed: | 3000pcs/H |

Parameter | APM-S102 |

Round container | |

Printing diameter | 20-100mm |

Printing length | 20-300mm |

Max.printing speed | 4000pcs/h |

Oval container | |

Printing width | 25-120mm |

Printing length | 25-300mm |

Max.printing speed | 5000pcs/h |

Square container | |

Printing length | 100-200mm |

Printing width | 40-100mm |

Max.printing speed | 4000pcs/h |

Machine dimension | 1908*1000*1500mm |

Power | 380V,3P,50/60Hz |

Air supply | 5-7bar |

Application

The APM-S102 is designed for multi-color decoration of cylindrical/ova/square/plastic glass bottles,cups,hard tubes at high production speeds. It is suitable for glass and plastic containers printing with UV ink. Need registration point for multi-color cylindrical bottle printing.

Reliability and speed make the S102 ideal for off-line or in-line 24/7 production.

General Description

Automatic 1-8 color screen printing line, each unit can be separated or connected;

Automatic loading system with belt and vacuum robot(bowl feeder and hopper optional;

Auto flame treatment;

Perfect transmission system. It passes over the bottles fast and smooth;

Automatic 180 degree rotation for oval and square bottles;

Quick and easy change over from one product to another;

LED UV curing system with longer life time and energy saving,electric UV system optional;

Reliable PLC control with touch screen display;

Promise of quality SMC pneumatic parts and Panasonic, Schneider Electric parts. Other brands optional;

Automatic unloading.

Procedure

Auto loading onto belt——flame treatment——printing——UV drying —— next color printing and drying——auto unloading

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886