Color Spray Paint Coating Machine Production Line

Color Spray Paint Coating Machine Production Line – A high-efficiency automated spraying solution designed for automobile bodywork, bumpers, interior trims, GPS casings, and irregularly shaped objects. Featuring a multi-axis robotic system, it ensures uniform coating, high material utilization, and precision-controlled spraying with 90%-95% efficiency. The system supports multi-angle spraying, offline programming for quick setup, and a modular design for easy maintenance. The spraying process includes preheating, dust removal, spraying, IR & UV curing, and vacuum plating, ensuring a smooth, durable finish. Customizable to specific production needs, it integrates seamlessly into automated lines.

Color spray paint coating machine production line

Working range:bodywork, bumper,Interior Trims,car GPS,large and anomaly work piece , and need to multi -angle spraying.

Brand : APM

Model:Customizable

Joint number: five shafts or more

Products characteristic and purpose

1.Good flexibility and facility utilization

Large radius and good flexibility

Can spraying at inside and outside

Spraying Robot can reach 90%-95% availability

Increase the quality of spraying and material use factor.

Precision copy at spraying contrail, increase uniformity coating and quality of the finished spraying.

Reduce of the dosage in spraying and cleaning resolvent, increase the material use factor.

Easy operation and maintenance

Off-line programming, cut down a lot Field commissioning time

plug-in unit structure and modularization design , high-speed install and replace component, cut down a lot service time.

Good maintenance in all of the components, convenient for servicing .

product purpose

Suitable for use products: bodywork, bumper, Interior Trims, car GPS, large and anomaly work piece , and need to multi -angle spraying.

Model: WA-101 1.0mm caliber from Japan

Origin: imported from JapanModel: WA-101 1.0mm caliber from Japan

Origin: imported from Japan

Color spray paint coating machine production line

| Model | Color spray paint coating machine production line |

| Brand | APM |

| Size | Customization |

| Customize | Yes |

| After-sales service | Provide professional after-sales service |

| Product Keywords | Color spray paint coating machine production line |

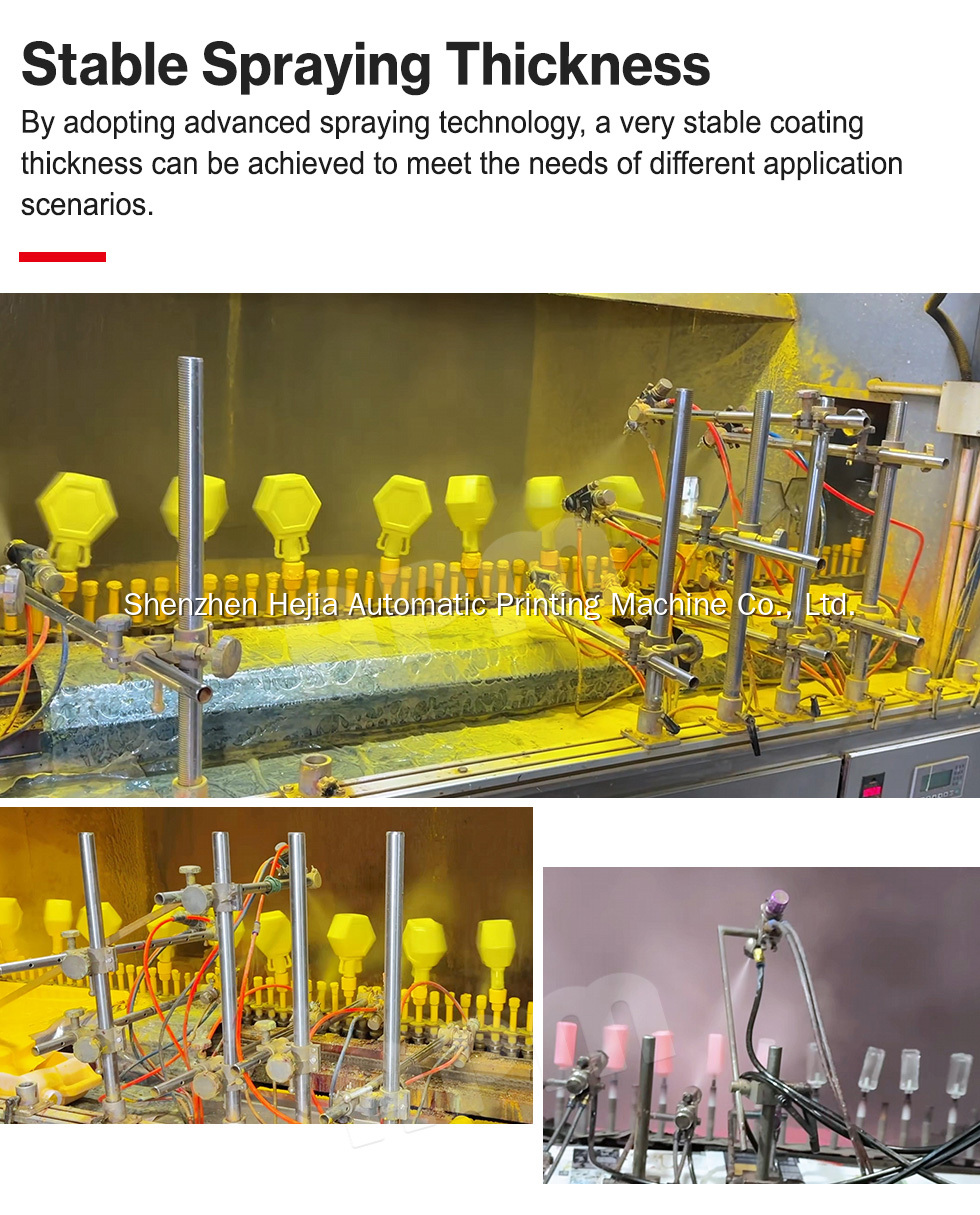

Spraying process:

Loading→ material preheat→flamedust abatement→static dust abatement→ printing→ IR →UV curing→loading→vacuum plating

Production Process

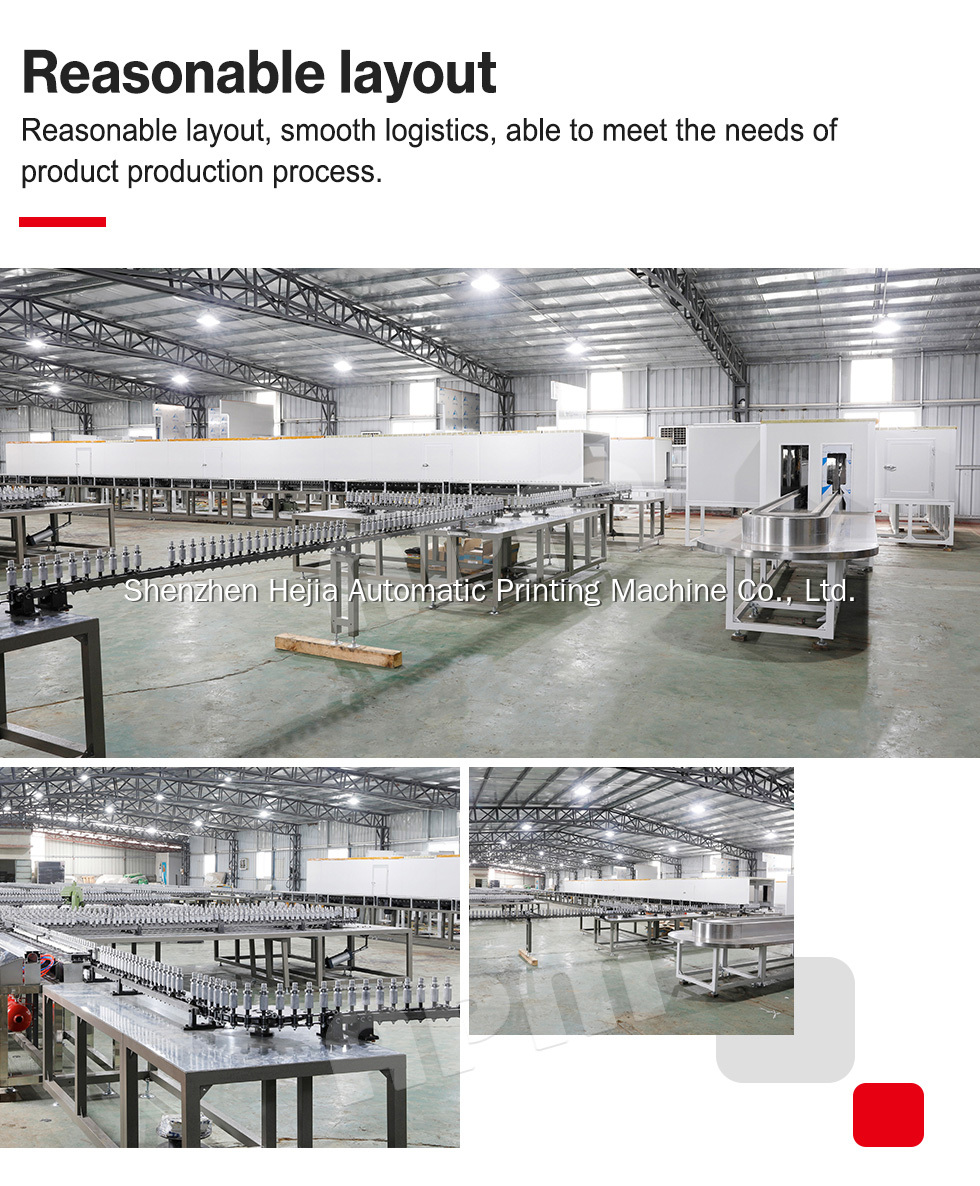

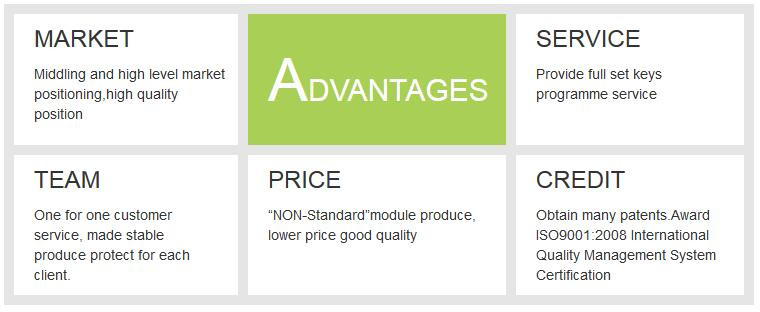

Companies adhere to the "quality first, customer first" principle, and in strict accordance with the ISO9001:2008 international quality management system, quality inspection personnel from the strict management of raw materials to the production assembly process inspection tour, and then to the product to be delivered the whole test, our employees high quality awareness, strict quality control, to ensure that qualified goods factory, factory to solve all problems. In order to eliminate the concerns of customers, the company special clerk on behalf of clients to set up a special team to test the machine debugging test of each equipment field, create high-quality products share light spraying equipment

1. Contract promised after-sales service commitment

2. After the completion of the commissioning/machine:

a) relevant materials and spare parts delivery

b) send professional spray technicians to operating personnel, maintenance of personnel training.

3. Set up exclusive customer profiles - "after-sales service file"

4. The initiative to make an appointment, on-site maintenance, monthly, quarterly active contact with maintenance

5. Maintain acceptance, use maintenance are also put forward for customer reference, record the customer feedback

6. Back to the factory the archive, and record it to the unfinished work in order to follow up in time

After-sales department development situation

Our company is the industry after the first actively.Under the influence of the financial crisis in 2008, the factory also naturally affected.In difficult circumstances, workers few things, in order to avoid loss, improve workers' production enthusiasm, firm contrarian active maintenance plan is put forward, the initiative door-to-door after-sales service for the customer.Through this move our harvest is very big:

1. Active after-sales behavior for customers to our liking, promote the friendly relationship with customers.

2. Improve the workers work enthusiasm, to avoid the staff turnover;

3. Can understand the needs of customers, under the environment of the financial crisis, in order to save the cost of the customer will choose to modify existing lines to reduce costs, because we have the professional equipment, consumable and procurement through to us.

From 2008 to now, we have the perfect after-sales service, insisted to provide quality after-sales service:

1. Installation and debugging equipment for the customer;

2. Send application professional technicians to spray commissioning and personnel training, for free on the use, maintenance and other aspects of spraying technology guidance:

3. To ensure maintenance spare parts supply, to help customers improve process, reduce the cost;

4. Timely maintenance and some maintenance advice to customers, to prevent problems;

With high quality good faith post-sale service work for many years, the company won the customer's widely recognized.Also let us have benefited a lot from, in the midst of after-sales, we can understand the procurement needs of customers in a timely manner, to equipment in the possible problems in the process of production, more understanding, reserve a large number of technical parameters for equipment research and development innovation, let the product strive for perfection.In the future, we will, as always, to provide quality good faith service, let customers choose us, choose peace of mind.a

Q1:Are you trading company or manufacturer?

A1:We are 100% manufacturer,professional supplier of spray painting line for over 12 years.

Q2:How hong is your delivery time?

A2:Generally it is 40-45 workdays,it is according to the layout.

Q3:What is your terms of payment?

A3:Multiple,we can disscuss.

Q4:What is your Pre-sales service?

A4: *Inquiry and consulting support.

*Technology solution and quotation.

*Customer visit our factory and check our production.

Q5:Where is factory? Can visit?

A5:Yes,of course.We located in Hanxishui Industrial Area, Chashan Town, Dongguan, Guangdong, China (Mainland)

You could fly to Shenzhen Baoan Airport/Guangzhou Baiyun Airport.Warmly welcome to visit us!

Q6:Could you provide the design for me?

A6:Absolutely,we can.We are a manufacturer and designer.Just let me know your product informations and requirements like product sizes,pictures,material,output,field map,technological process,or price budget and so on.We will make a layout according to your requirments.

Contact: Alice Zhou,Email: slaes @apmprinter

Phone/Wechat/Whatsapp: +8618100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886