China Factory Robot Painting Shop Powder Coating Line Online Sale For Auto Part

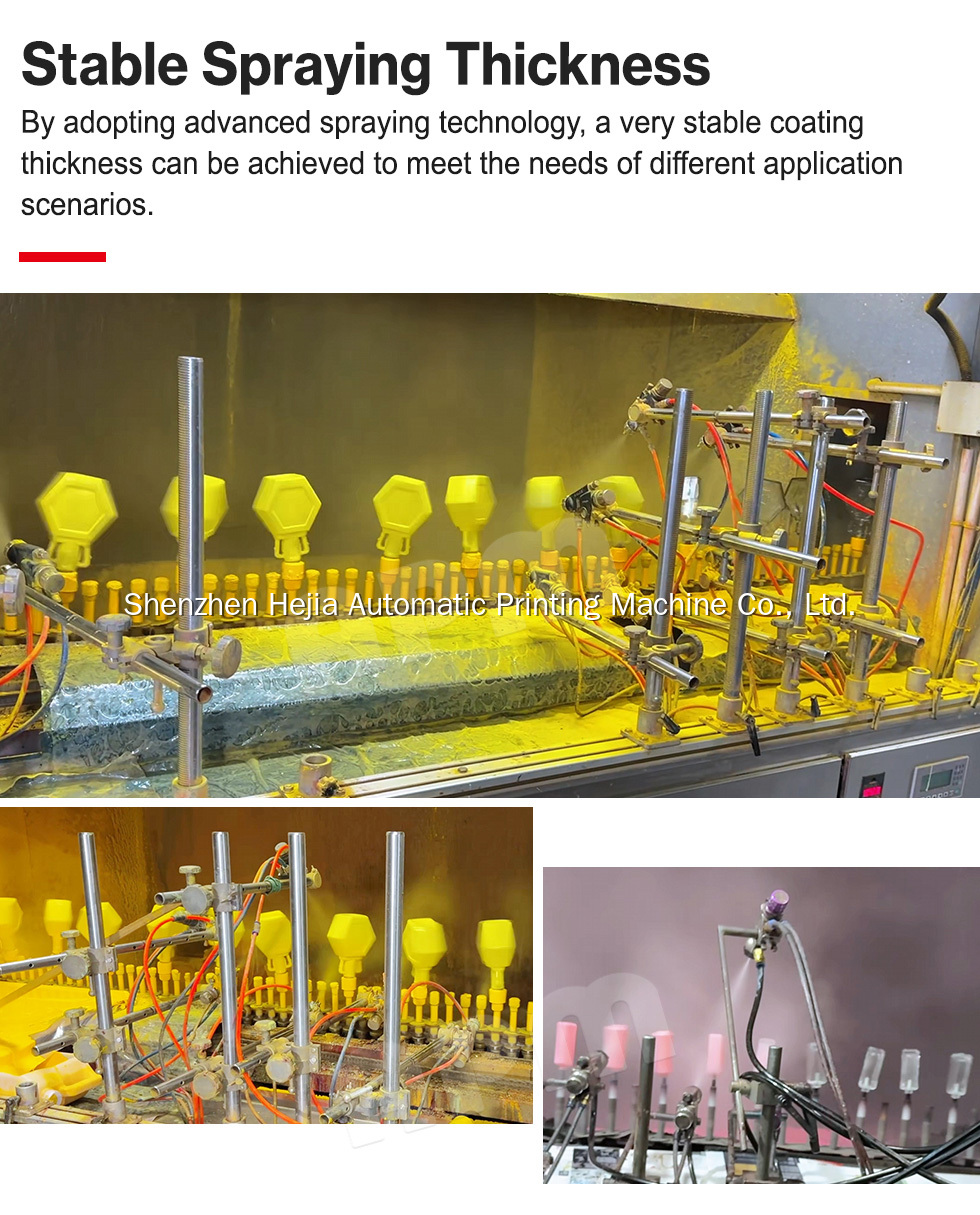

China Factory Robot Painting Shop Powder Coating Line offers an efficient and high-quality solution for automotive parts coating. With advanced robotic spraying technology, it ensures uniform coverage and excellent adhesion. The system integrates both powder coating and automated functions to maximize productivity, reduce waste, and enhance finish quality. Suitable for various auto parts, this line delivers durable, eco-friendly coatings with minimal material usage. Its customizable design and energy-efficient features make it a cost-effective choice for large-scale production. Perfect for businesses looking to improve coating quality and operational efficiency.

The Industrial Tunnel IR Oven & UV Oven is a high-performance drying and curing solution designed for electrostatic spray painting lines. It ensures fast, uniform, and energy-efficient curing for automotive, electronics, and industrial applications. This system integrates infrared (IR) heating and ultraviolet (UV) curing to enhance coating adhesion, surface smoothness, and durability, making it an ideal choice for large and complex workpieces.

1. High-Performance Heating & Curing

✅ IR Oven – Provides rapid heating & deep penetration for efficient solvent evaporation.

✅ UV Oven – Ensures fast curing with superior hardness & scratch resistance.

✅ Energy-Efficient Drying – Reduces curing time & power consumption.

2. Optimized for Complex Workpieces

✅ Multi-Angle Heating – Perfect for bumpers, interior trims, and large components.

✅ Consistent Curing – Guarantees uniform heat distribution & high-quality finishes.

✅ 90%-95% Material Utilization – Reduces waste & maximizes efficiency.

3. Flexible & Modular Design

✅ Customizable Model – Tailored for various part sizes & coating requirements.

✅ Plug-and-Play Installation – Easy setup, maintenance, and component replacement.

✅ PLC + CNC Control System – Enables precise temperature & conveyor speed adjustment.

1. Heating Type: Infrared (IR) & Ultraviolet (UV)

2. Curing Speed: Adjustable, optimized for electrostatic spray painting

3. Temperature Control: PLC system with touch-screen interface

4. Workpiece Compatibility: Bodywork, bumpers, interior trims, electronic casings, etc.

5. Material Utilization: 90%-95% coating efficiency

The IR & UV Oven System is ideal for:

✅ Automotive Industry – Car bumpers, dashboards, GPS casings.

✅ Electronics & Appliances – Mobile phone covers, laptop shells.

✅ Industrial & Consumer Goods – Lighting fixtures, furniture coatings.

✅ Luxury Packaging & Cosmetics – Perfume bottles, cosmetic caps.

1. Faster Curing Times – Improves production efficiency & reduces drying time.

2. Superior Surface Quality – Achieves high-gloss, durable, and uniform finishes.

3. Energy-Efficient Technology – Minimizes power consumption & operational costs.

4. Customizable Solutions – Designed to fit specific production needs.

1. What types of coatings can be cured in this oven?

✅ IR Oven – Ideal for solvent-based coatings, powder coatings, and waterborne paints.

✅ UV Oven – Suitable for UV-curable coatings requiring fast curing & high durability.

2. What industries commonly use this system?

✅ Automotive – Bumpers, dashboards, interior trims, GPS casings.

✅ Electronics – Mobile phone covers, laptop panels, home appliances.

✅ Industrial & Consumer Goods – Furniture coatings, lighting fixtures.

✅ Luxury Packaging & Cosmetics – Perfume bottles, cosmetic caps.

3. How does the IR oven work?

✅ Uses infrared radiation to heat and dry coatings efficiently.

✅ Fast solvent evaporation ensures smooth & durable finishes.

✅ Energy-efficient drying reduces power consumption.

4. What is the advantage of UV curing?

✅ Instant drying – No waiting time, increases productivity.

✅ Stronger adhesion – Creates a scratch-resistant & high-gloss finish.

✅ Eco-friendly – No VOC emissions, reducing environmental impact.

5. Can the oven handle different workpiece sizes?

✅ Yes! The system is customizable for various part sizes and coating requirements.

✅ It supports large & complex components needing multi-angle curing.

6. How is temperature controlled?

✅ PLC + CNC Control System allows precise temperature & conveyor speed adjustments.

✅ Touch-screen operation for easy setup and real-time monitoring.

7. What are the energy-saving features?

✅ Optimized heat distribution reduces power consumption.

✅ Efficient UV lamps minimize energy waste while ensuring rapid curing.

8. Is the system easy to install and maintain?

✅ Modular plug-and-play design for quick installation & minimal downtime.

✅ Easy component replacement ensures smooth operation & reduced maintenance costs.

9. What are the space and power requirements?

✅ The system can be customized based on available space & production needs.

✅ Compact layout options are available for space-saving installations.

10. How can I get a quote or more details?

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886