Fully Automatic Bottle Cup Screen Printer

The APM-S102 is designed for multi-colour decoration of cylindrical/oval/square plastic/glass bottles, cups, and hard tubes at high production speeds. It is suitable for glass and plastic container printing with UV ink. Need registration point for multi-colour cylindrical bottle printing. Reliability and speed make the S102 ideal for off-line or in-line 24/7 production.

The Fully Automatic Plastic Bottle Screen Printing Machine is designed for high-precision printing in the cosmetics, food, pharmaceutical, and daily chemical industries. It is suitable for cylindrical, oval, and square bottles. Equipped with a high-precision servo control system, this machine ensures accurate printing with automatic alignment, UV curing, and an efficient conveyor system. The PLC touchscreen control simplifies operation, making it an ideal choice for high-volume, high-quality production.

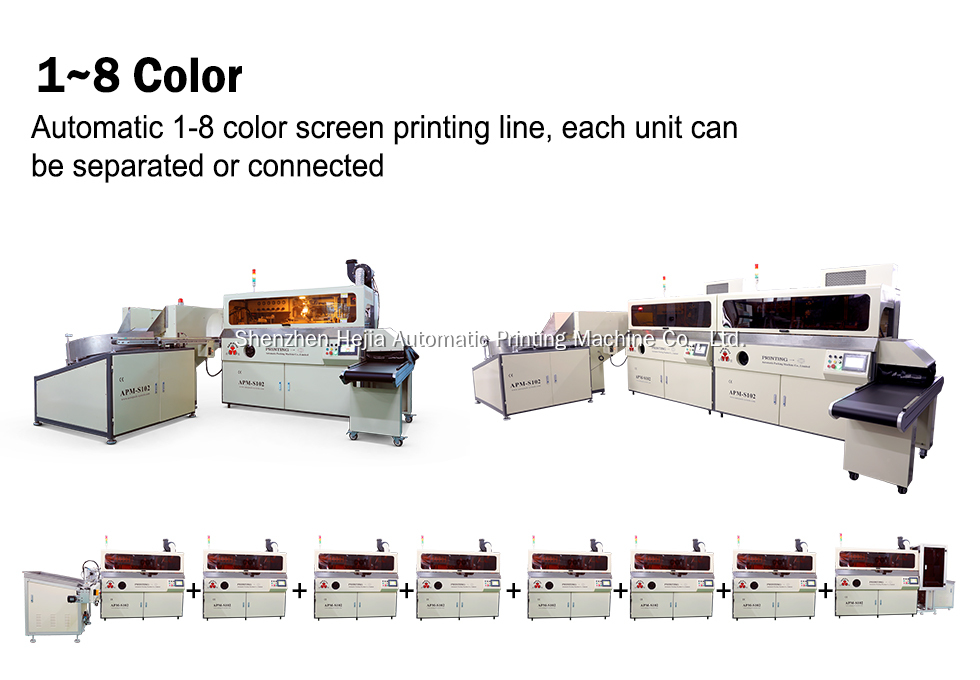

1. ✅1 to 8 Color Printing: Perfect for detailed, multi-color designs.

2. ✅Suitable for Cylindrical, Oval, and Square Containers: Versatile for all types of bottles and tubes.

3. ✅High-Speed Operation: Prints up to 5000 pcs/hr depending on the container type.

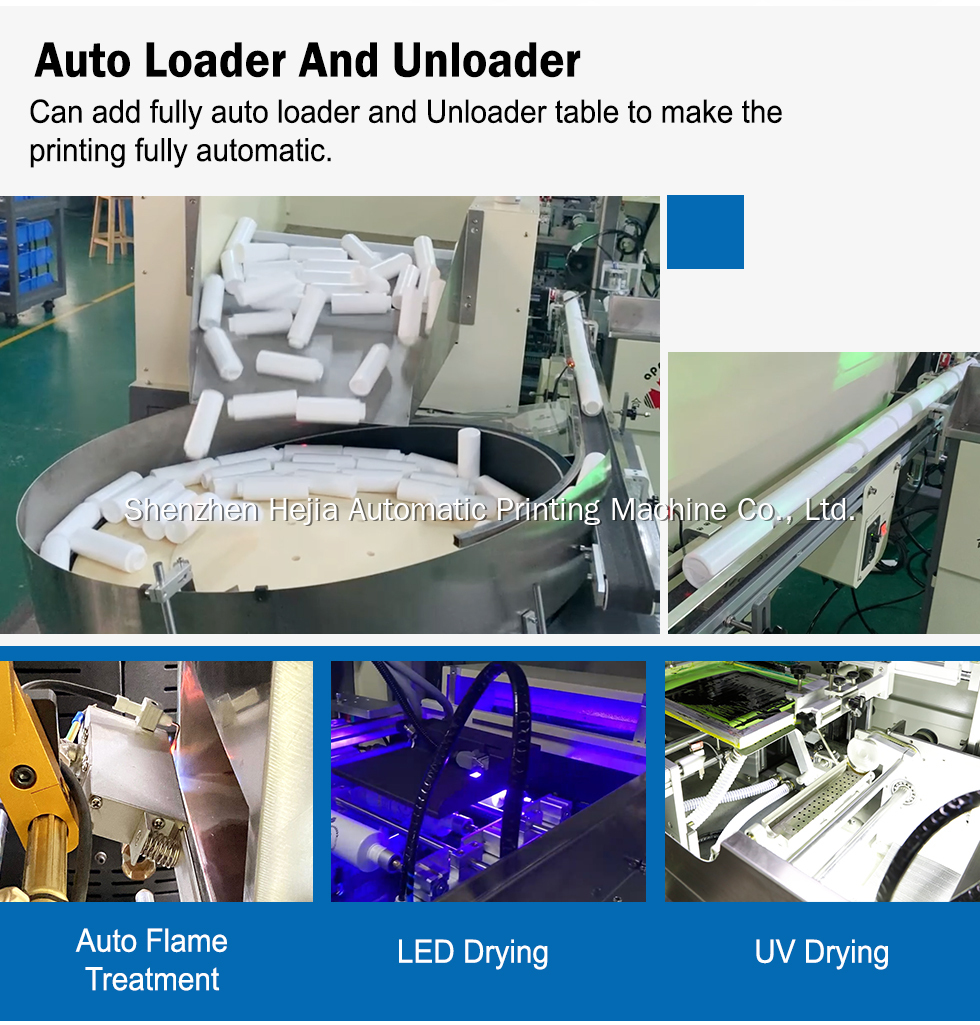

4. ✅Auto Loading & Unloading: Fully automated for efficient production.

5. ✅Flame Treatment: Ensures perfect adhesion of prints on various materials.

6. ✅Reliable PLC Control: Easy-to-use touchscreen interface for control and monitoring.

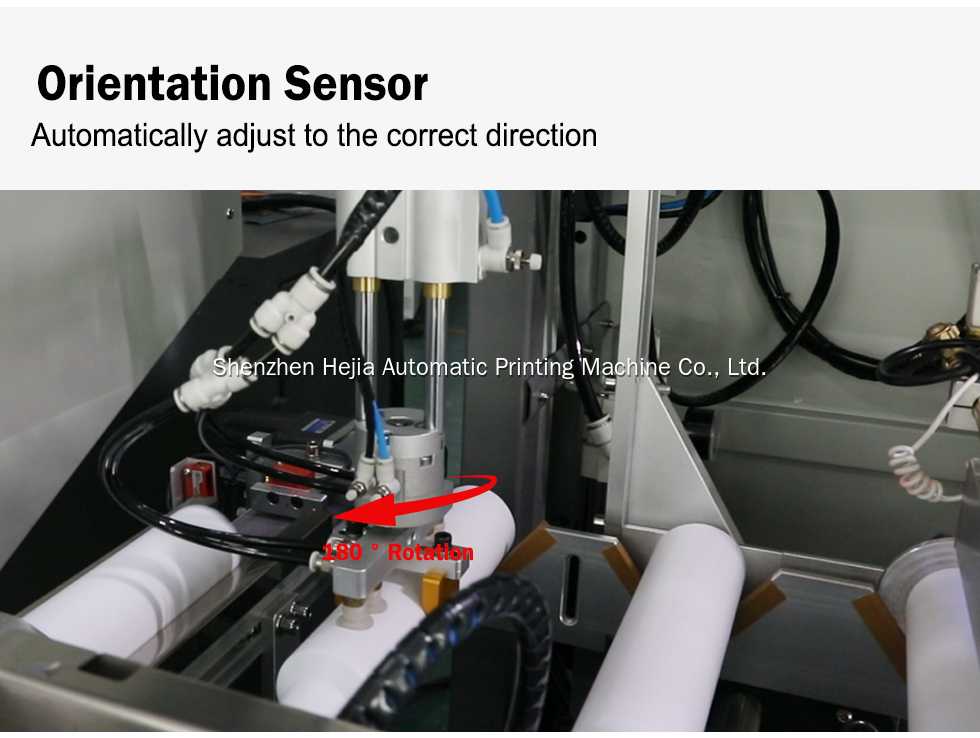

7. ✅Automatic Rotation: For oval and square containers, ensuring consistent printing.

8. ✅UV/LED Drying System: Fast drying process for durable prints.

9. ✅Quick Changeover: Easily switch between different products.

Technical Specifications | Parameters |

Max Speed | 3000-5000 pcs/hr (depending on container type) |

Printing Diameter (Round Containers) | 25–100mm |

Printing Length (Round Containers) | 150–280mm |

Max Printing Radius (Oval Containers) | R20–R250mm |

Max Printing Length (Square Containers) | 100-200mm |

Power Supply | 380V 3P, 50/60Hz, 6.5kW |

Air Consumption | 5-7 bars |

This machine is widely used in the cosmetics, food, pharmaceutical, and daily chemical industries for high-precision screen printing on various bottles, including but not limited to:

1.✅ Cosmetic Bottles – Lipstick tubes, serum bottles, foundation bottles

2.✅ Beverage Bottles – Glass bottles, plastic bottles, sports water bottles

3.✅ Pharmaceutical Bottles – Plastic medicine bottles, glass ampoules, reagent bottles

4.✅ Daily Chemical Products – Shampoo bottles, disinfectant bottles, skincare containers

1. What types of bottles can this machine print on?

✅ It is suitable for cylindrical, oval, and square plastic and glass bottles, including cosmetic, pharmaceutical, and food containers.

2. Does the machine support multi-colour printing?

✅ Yes, the machine supports 1-6 color screen printing with high-precision alignment.

3. Is UV curing necessary?

✅ Yes, UV curing ensures instant drying, stronger adhesion, and better durability.

4. Can the machine handle different bottle sizes?

✅ Yes, the quick mould change system allows adjustments for different bottle sizes and shapes.

5. What is the production speed?

✅ Up to XX pcs/hour, depending on the bottle shape and printing requirements.

6. Does the machine comply with international certifications?

✅ Yes, the machine is CE-certified and meets international safety and quality standards.

7. How long is your warranty period?

✅Our warranty period is up to one year.

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886