APM PRINT - LED UV system glass bottle silk screen printing machinery Auto Screen Printer

Having invested a great deal of funds to technology research and product development,Shenzhen Hejia Automatic Printing Machine Co., Ltd. has successfully worked out LED UV system glass bottle silk screen printing machinery. LED UV system glass bottle silk screen printing machinery with reasonable price, excellent performance and excellent quality, it has won wide recognition from customers. Our expertise and technologies enable tailor-made solutions for every customer.

| Plate Type: | Screen Printer | Applicable Industries: | Manufacturing Plant, Printing Shops |

| Condition: | New | Place of Origin: | Guangdong, China |

| Brand Name: | APM | Usage: | glass bottle printer |

| Automatic Grade: | Automatic | Color & Page: | single color |

| Voltage: | 380v, 50/60Hz | Dimensions(L*W*H): | 2200x1320x1800mm |

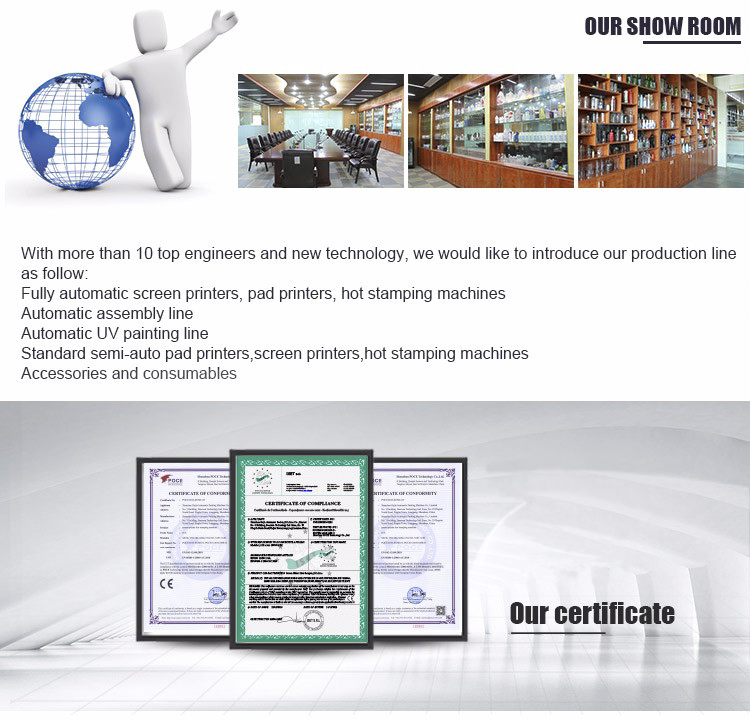

| Weight: | 800 KG | Certification: | CE Certification |

| Warranty: | 1 Year | After-sales Service Provided: | Online support, Video technical support, Engineers available to service machinery overseas |

| Key Selling Points: | Automatic | Machinery Test Report: | Provided |

| Video outgoing-inspection: | Provided | Warranty of core components: | 1 Year |

| Core Components: | Motor, PLC | Application: | Round, Square, irregular Container Printing |

| Printing Speed: | 1800-2400 pcs/h | After Warranty Service: | Video technical support, Online support, Spare parts, Field maintenance and repair service |

| Local Service Location: | United States, Spain | Showroom Location: | United States, Spain |

| Marketing Type: | Ordinary Product |

| speed | 1800-2400pcs/H |

| power | 380V, 3P 50/60Hz |

| Air supply | 6-8Bar |

| Round Container | |

| Printing Dia. | 20-100mm |

| Printing Length | 30-180mm |

| Square/Irregular container | |

| Printing Width | 20-100mm |

| Printing Length | 30-180mm |

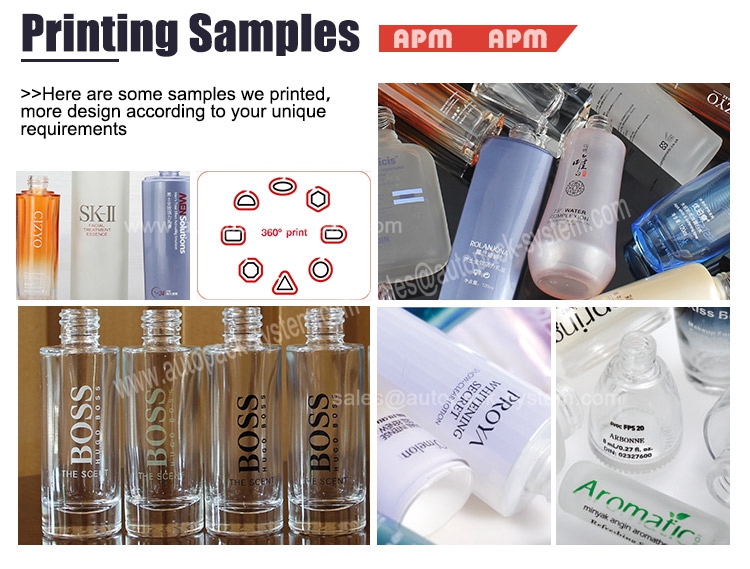

Application

Application

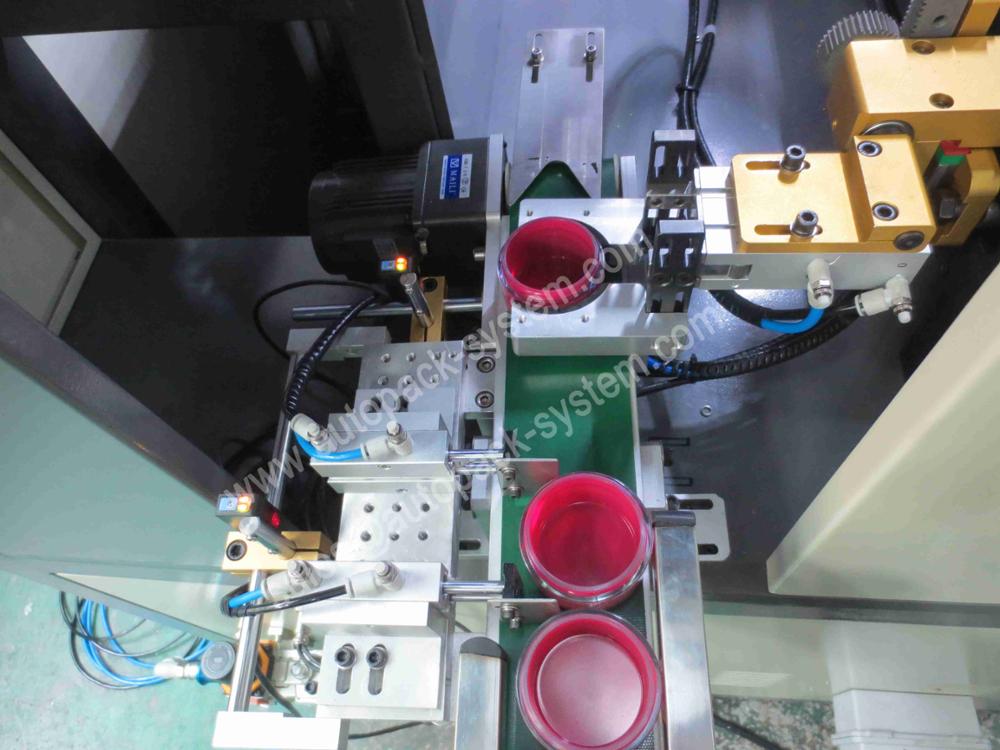

All shapes of glass bottles, cups, mugs. It can print any shape of containers all around in 1 print.

General Description

1. Automatic loading system with multi axis servo robot.

2. Servo driven transfer system.

3. Auto flame treatment

4. Automatic printing system with all servo driven: printing head, mesh frame, rotation, container up/down all driven by servo motors.

5. Multi sides printing in one process.

6. Auto UV drying

7. Super quick and easy change over from one product to another.

8. All parameters automatic setting simply in touch screen. Product change is 15 minutes only per color.

9. Automatic unloading with servo robot.

10. Safety operation with CE.

11. Repeat print to be multi colors.

Options

Camera vision system, for cylindrical products without registration point.

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886