Single Color Servo Driven Screen Printer for cylindrical products

The monochrome servo screen printer supports printing with solvent-based inks and thermoplastic inks. It is used for printing on cosmetic bottles, medicine bottles, food packaging and other applications with high adhesion and weather resistance. It is equipped with a variety of technologies to achieve fully automated production.

The Single Color Servo Driven Screen Printer is designed for cylindrical bottles and jars, supporting solvent ink and thermoplastic ink printing. It meets high-adhesion and weather-resistant printing needs for cosmetic bottles, medical jars, and food packaging. Equipped with multi-axis servo robots, intelligent drying systems, and ultra-fast mould change technology, it achieves fully automated production from loading to printing and drying.

1. Fully Automated Servo-Driven Process

✅Smart Loading: Multi-axis servo robots pick and place bottles from the conveyor belt to the printing station.

✅Robot Transfer: Servo arms seamlessly connect printing and drying processes, ensuring consistent quality.

✅Upright Unloading: Printed bottles are placed upright on the unloading belt for stability.

2 . Efficient Solvent/Thermoplastic Ink Printing

✅Wide Compatibility: Supports solvent ink (with clamp space) and thermoplastic ink for corrosion resistance and high gloss.

✅IR Drying System: Integrated infrared drying on the unloading belt ensures fast curing and residue-free surfaces.

3 . Quick Changeover & Intelligent Control

✅15-Minute Color Change: Modular design + automatic parameter storage enables rapid product switching.

✅One-Touch Adjustment: Preset printing pressure, speed, and drying time via touchscreen.

4. High Precision & Stable Production

✅Servo Control: Printing alignment accuracy of ±0.05mm, speed up to 2400 pcs/hour, yield rate >99.5%.

✅CE Certification: Emergency stop, protective covers, and self-diagnosis ensure safe operation.

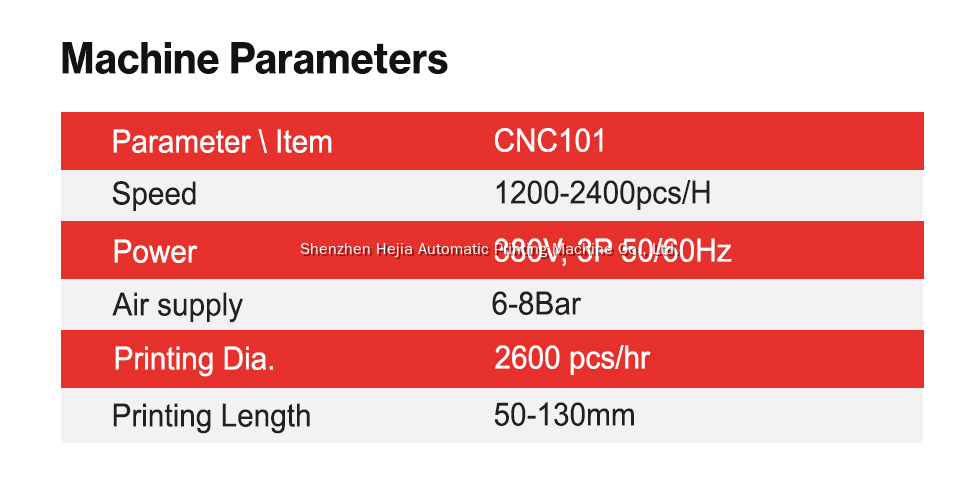

speed | 1200-2400pcs/H |

power | 380V, 3P 50/60Hz |

Max. product height | Air supply |

Printing Dia. | 10-60mm |

Machine weight | 700-800KG |

Printing Length | 50-130mm |

Solvent Ink: Industrial bottle labelling (e.g., detergent bottles, pesticide jars).

Thermoplastic Ink: Food-grade packaging (e.g., jam jars, beverage bottles), cosmetic logos.

High-Precision Printing: Medical bottle scales, and anti-counterfeit labels on glass bottles.

Customization: Optimized clamp space for solvent ink printing.

Global Delivery: Ships within 15 working days, with on-site installation and training.

Warranty: 1-year full machine warranty, lifetime support for key components.

1. What is a Single Color Servo Driven Screen Printer for cylindrical products?

✅ The Single Color Servo Driven Screen Printer is a fully automatic machine designed specifically for cylindrical bottles. It uses advanced servo systems to ensure precise pressure, alignment, and speed control, making it ideal for high-quality single-colour printing.

2. How does the Single Color Servo Driven Screen Printer outperform traditional machines?

✅ The Single Color Servo Driven Screen Printer offers three key upgrades:

Full Automation: From loading to unloading, it achieves speeds up to 2400 pcs/hour.

Quick Changeover: 15-minute colour change vs. 2+ hours on traditional machines.

Ink Compatibility: Supports both solvent and thermoplastic inks for diverse needs.

3. Can the Single Color Servo Driven Screen Printer print non-cylindrical bottles?

✅ The Single Color Servo Driven Screen Printer is optimized for cylindrical products (e.g., lipstick tubes, cans). For oval or square bottles, consider our multi-colour models.

4. Are special configurations needed for solvent ink on the Single Color Servo Driven Screen Printer?

✅ Yes, the Single Color Servo Driven Screen Printer requires clamp space to avoid contamination when using solvent ink. IR drying is also recommended for fast curing.

5. How is the 15-minute colour change achieved on the Single Color Servo Driven Screen Printer?

✅ The Single Color Servo Driven Screen Printer achieves this through modular printing units and servo memory:

After replacing screens and fixtures, parameters are automatically recalled.

Servo systems reset precisely, minimizing downtime.

6. How stable is the Single Color Servo Driven Screen Printer?

✅ The Single Color Servo Driven Screen Printer guarantees:

±0.05mm alignment accuracy and >99.5% yield rate.

CE-certified safety features (emergency stop, light curtains, air pressure monitoring).

Key components from Mitsubishi/Siemens ensure <0.3% failure rate.

7. Does the Single Color Servo Driven Screen Printer support IoT remote monitoring?

✅ Yes, the Single Color Servo Driven Screen Printer offers an optional IoT module for real-time production data (speed, yield, error codes) and mobile alerts.

📩 Contact us today for a customized solution tailored to your production needs! 🚀

Alice Zhou

📧 sales@apmprinter.com

📞 +86 18100276886

LEAVE A MESSAGE

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886