How to choose which type of APM screen printing machines?

The customer who visit our booth in K2022 bought our automatic servo screen printer CNC106.

Here are their questions and our answers:

On the website of APM company, I see the print screen machines that presented by you in the k exhibition. Please explain to me whether APM is the manufacturer of the print screen machines in China? We are manufactuerer in China with 25 years experience.

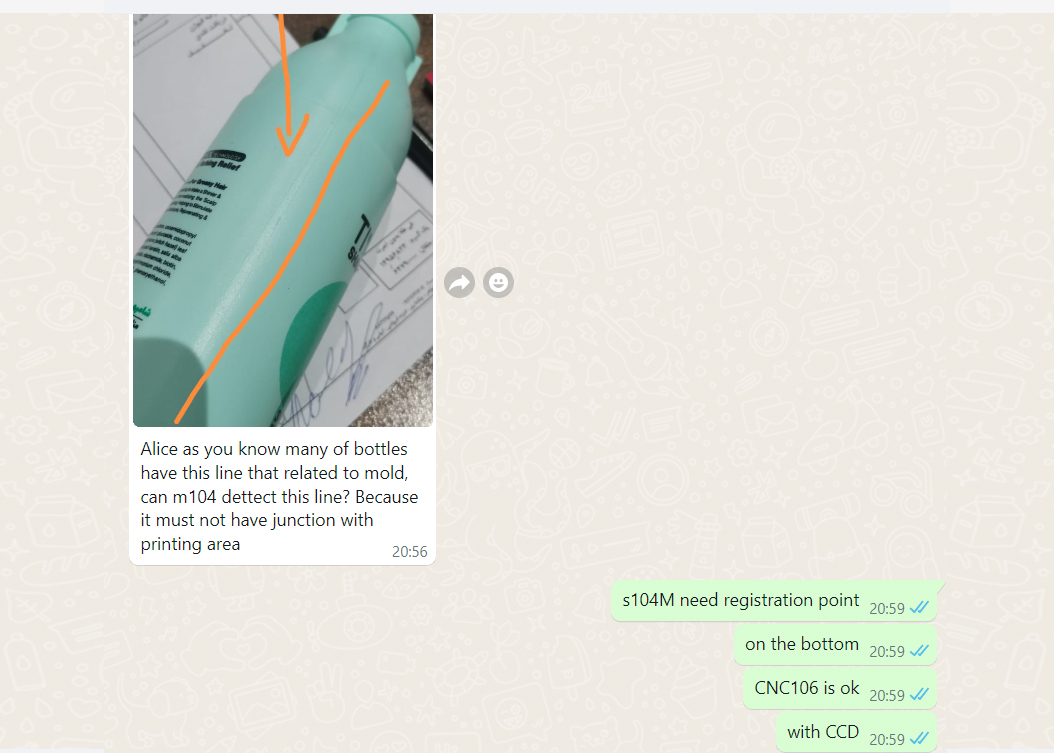

Regarding the S104M print screen machine, do we need a register point for printing or not? because we prefer not to depend on that for printing and printing on containers be independent of it. Because it is written in the description of this machine on the company's website (https://www.apm-print.com/auto-screen-printer/automatic-cap-screen-printer.html) that there is no need for this point on the container, but you explained to me at the exhibition that our container must have a register point or use a camera instead of that.

If you want to print escape molding line or first color has be on proper left-right position, then need registration point. If don’t have this, you can use our other machine CNC106 with CCD registration.

If registration you means other colors should match the first color position, then S104M is ok, we call this color registration.

● As you know the plastic bottles produced by blow molding technic and in this method all bottles and another containers may be not similar together. Actually In some cases, containers have differences from each other in shape and size, or deformation is seen in them which can affect the uniform printing and increase the waste. What is your suggestion about this problem ?

If tolerance not very big, then ok, what is your tolerance?

● Does the S104M machine have the ability to increase the printing station? Because this machine had 3 printing stations and we need more stations for some products.

Need to decide the stations at the beginning but you can turn off if no need to use. Most time we make 3 color, sometimes 2, 4, 5 colors.

●Is it possible to add a station for hot stamping in the S104M device or not?

S104M is not good for stamp, so better buy a separate semi auto hot stamping machine or use CNC106.

6- Is it possible to use vision control in the S104M device?

Sorry, this machine no space for CCD. But we install CCD on CNC106.

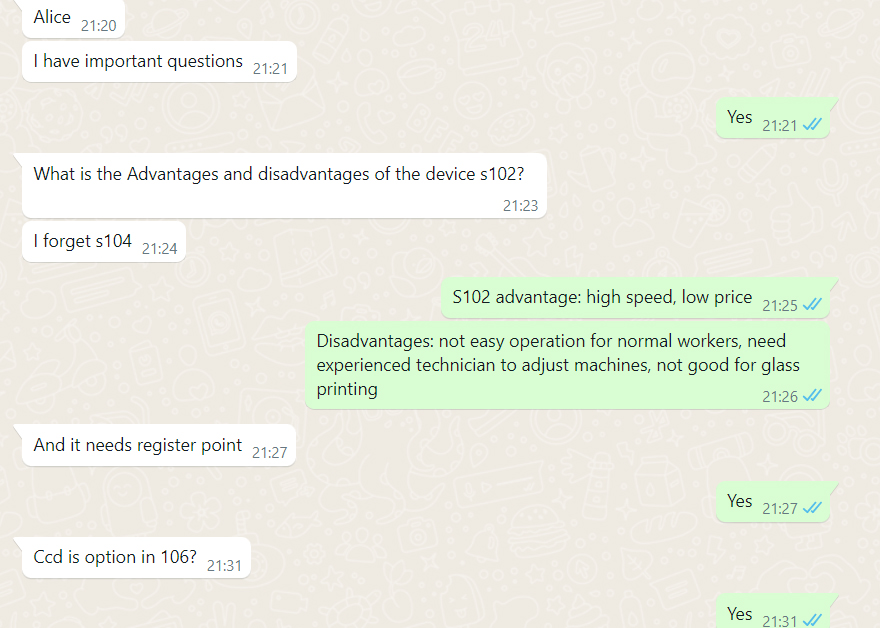

● What is the difference between the S104M machine and the cnc 106 multi-color (https://www.apm-print.com/auto-screen-printer/multicolor-bottle-automatic-screen-printer.html) machine? Please answer this question without considering the printing stations. Because I know that the s104M machine has 3 printing stations and it is linear machine and the cnc 106 multi-color machine has more than 6 printing stations and it is cicular machine .

● CNC106 with high speed and can print big quantity, normally has 10-12 fixtures, S104M is with lower speed but easy to change fixtures, only 1-2 fixtures, the operator who could operate semi auto machine can run this machine.

● CNC106 can print escape molding line for the first color with CCD registration.

S104M no space for CCD.

● As you explained, this S104M machine is modular. Is it possible for us to have a machine with two printing stations and increase these stations after a while?

This machine no. But it is ok for S102.

● How does the machine control bottle in input and output? And what defects can it control? For example if the bottle has defect in input the machine can reject it before the entrance of machine or not? And in output can it control the quality the print on bottles?

You need to buy extra quality detect system, but for now no very good ones in the world and cost very high. So better detect by people. If machine test very well, then should be no problem for printing quality.

● Can we print the image by S104M machine on each type of container shape or not? ( attached picture No.1)

It can print round, oval and square. But better not print images like a photo.

● According to website, this type of machine prints a wide range of bottle sizes, so how does the machine fixtures change size by size? For example I have some bottles with 25 mm to 100 mm in diameter, should we buy 2 machines or can we have one machine for these ranges of dimensions?

You can use one machine to do this.

But if buy 2 machines, one for small bottles, one for bigger bottles, it will be easier to adjust.

● Which type of dryer are you going to suggest? UV dryer or led dryer?

S104M can only install with LED dryer. S102, CNC106 are suitable for UV, LED drying.

● How we can adjust mesh frame and printing head? It is manual or the machine does by servodrive ?

Some operations manual, some parameters set in touch screen by servo driven (for example diameter, printing stroke...), our technicians combine together.

15- As I understand, the number of stations required for printing can be achieved by placing the s102 machine together. Actually we must connect the S102 s together for achieving more color station .

Know, main question: what is different between S104M and 3 of S102 which is connected together ?

S102 is mechanical, need professional tehcnicion to adjust it and change products.

S102 normally good for plastic bottles, but also can print glass bottles.

For 3 color S104M, only 1-2 fixtures, S102 with 3 sets fixtures(6pcs) and some transfer parts.

You need to choose machine according to product quantity and budget. (If every type bottle less than 100,000pcs, then choose S104M). Otherwise choose CNC106 or S102

QUICK LINKS

PRODUCTS

CONTACT DETAILS

Fax: +86 - 755 - 2672 3710

Mobile: +86 - 181 0027 6886

Email: sales@apmprinter.com

What sapp: 0086 -181 0027 6886